Creative Woodworks & crafts 1998-07, страница 24

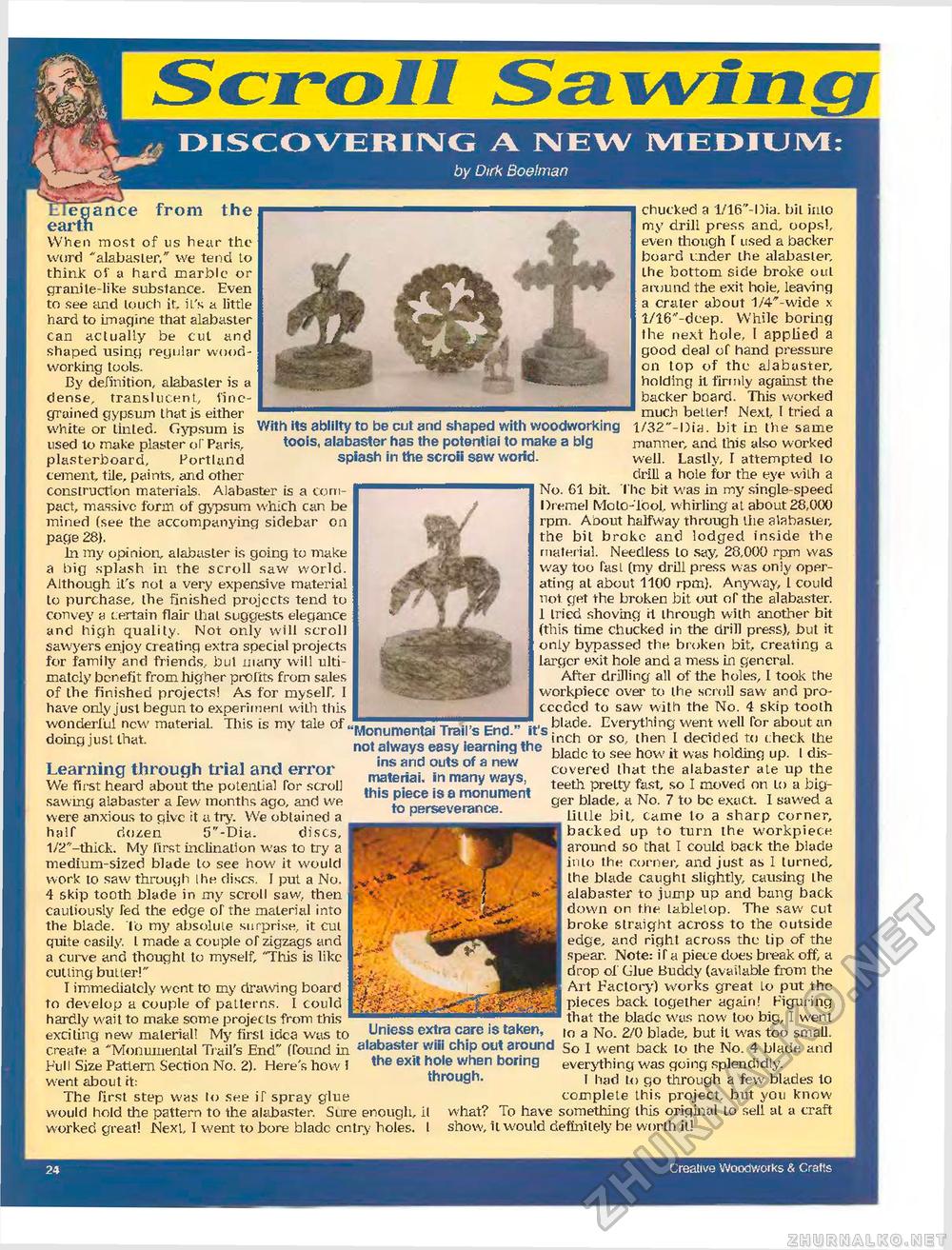

ance from the earth When most of us hear the word "alabaster," we tend to think of a hard marble or granite-like substance. Even to see and touch it, it's a little hard to imagine that alabaster can actually be cut and shaped using regular woodworking tools. By definition, alabaster is a dense, translucent., Vine-grained gypsum that is either white or tinted. Gypsum is used to make plaster of Paris, plasterboard, Portland cement, tile, paints, and other construction materials. Alabaster is a torn-pact, massive form of gypsum which can be mined (see the accompanying sidebar on page 28). In my opinion, alabaster is going to make a big splash in the scroll saw world. Although it's not a very expensive material lo purchase, the finished projects tend to convey a c ertain flair that suggests elegance and high quality. Not only will scroll sawyers enjoy creating extra special projects for family and friends., but many will ultimately benefit from higher profits from sales of the finished projects! As for myself. I have only just begun to experiment wiLh this wonderful new material. This is my tale of, doing just that. With its ability to be cut and shaped with woodworking tools, alabaster has the potential to make a big spiash in the scroii saw world. Learning through trial and error We first heard about the potential Tor scroll sawing alabaster a few months ago, and we were anxious to give it a try. We obtained a half dozen 5"-Diy. discs, 1/2*-thick. My first inclination was to try a medium-sized blade to see how it would work to saw through the discs. I put a No. 4 skip tooth blade in my scroll saw, then cautiously fed the edge of the material into the blade. Id my absolute surprise, it Cut quite easily. I made a couple of zigzags and a curve and thought to myself, 'This is like cutting butter!" I immediately went to my drawing board to develop a couple of patterns. I could hardly wait to make some projec ts from this exciting new material! My first idea was to create a "Monumental Tr ail's End" (found in Full Size Pattern Section No. 2). Here's how I went about it: The first step was to see if spray glue would hold the pattern to the alabaster. Sure enough, it worked great! Next, I went to bore blade entry holes. I chucked a l/lS"-l)ia. bit into my drill press and, oops!, even though [ used a backer board under the alabaster, the bottom side broke out around the exit hole, leaving a crater about 1/4"-wide x l/16"-dcep. While boring the next hole, I applied a good deal of hand pressure oil top of the alabaster, holding it firmly against the backer board. This worked much better! Next, I tried a l/32"-l)ia. bit in the same manner, and this also worked well. Lastly, I attempted lo drill a hole for the eye with a No. 61 bit. The bit was in my single-speed I) rem el Molo-'lool, whirling at about 28,000 rpm. About halfway through the alabaster, the bit broke and lodged inside the material. Needless to say, 28,000 rpm was way too fast (my drill press was only operating at about 1100 rpm). Anyway, 1 could not get the broken bit out of the alabaster. 1 tried shoving it through with another bit (this time chucked in the drill press), but it only bypassed the broken bit, creating a larger exit hole and a mess in general. After drilling all of the holes, I took the workpiecc over to the scroll saw and proceeded to saw with the No. 4 skip tooth .. — . , t -,, r- j » r», blade. Everything went well for about tin 'Monumental Trail's End. its inch Qr £0 > * decidecI t() (hetk the not always easy teaming the b]adc to see h ft was ho]din , dis_ .ns and outs of a new ^^ ^ the alabaster ^e' up the teeth pretty fast, so I moved on to a bigger blade, a No. 7 to be exact. 1 sawed a little bit, came lo a sharp corner, backed up to turn the workpiece around so that I could back the blade into the corner, and just as 1 turned, the blade caught slightly, causing the alabaster to jump up and bang back down on the tabletop. The saw cut broke straight across to the outside edge, and right across the tip of the spear. Note: if a piece does break off, a drop of Glue Buddy (available from the Art Factory) works great Lo put the pieces back together again! Figuring that the blade was now too big, I went lo a No. 2/0 blade, but it was too small. So 1 went back to the No. 4 blade and everything was going splendidly. I had to go through a few blades to complete this project, but you know what? To have something this original to sell at a craft show, it would definitely be worth it! material, in many ways, this piece is a monument to perseverance. Uniess extra care is taken, alabaster will chip out around the exit hole when boring through. 24 Creative Woodworks & Crafts |