Creative Woodworks & crafts 2001-04, страница 61

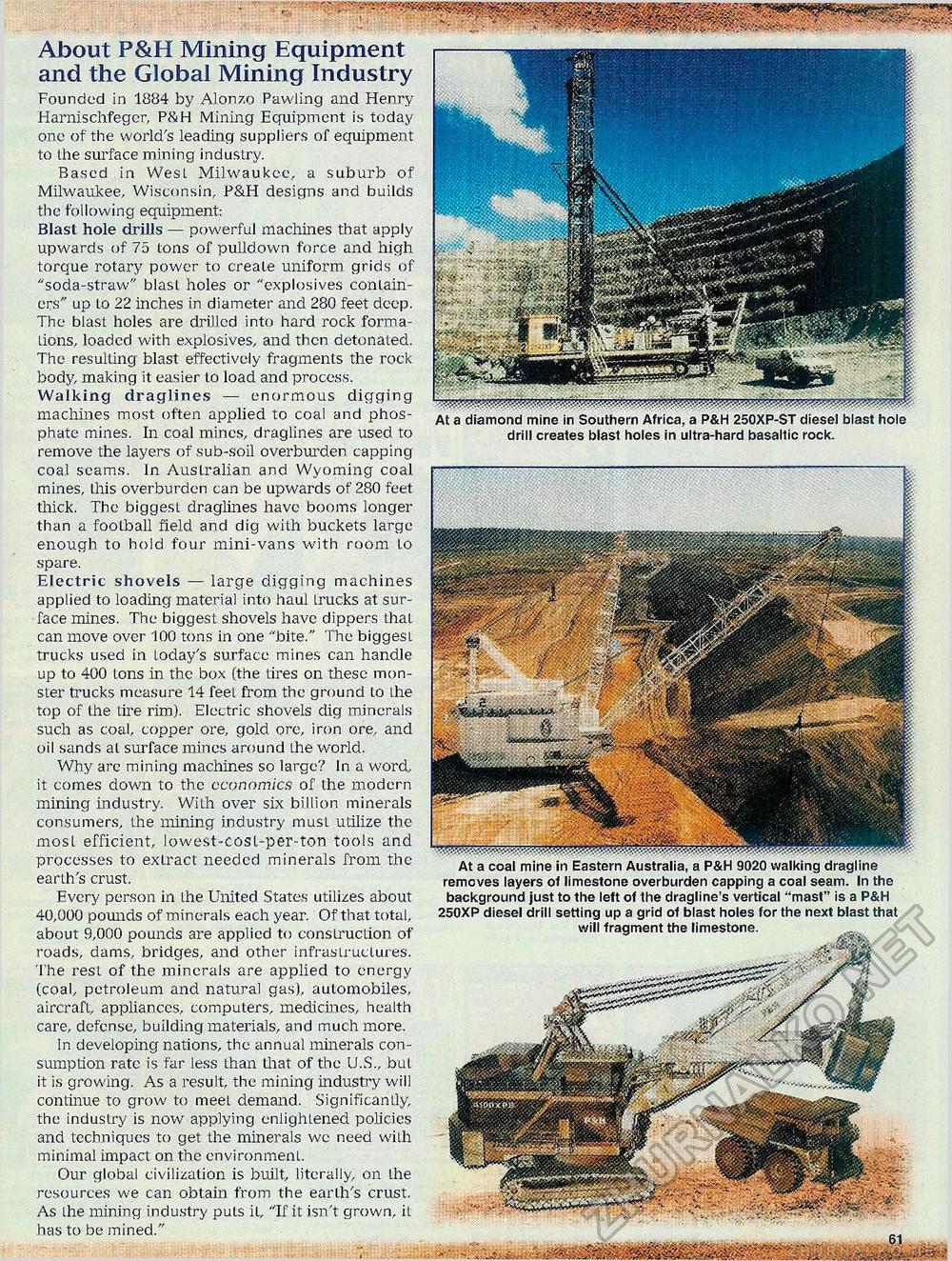

About P&H Mining Equipment and the Global Mining Industry Founded in 1884 by Alonzo Pawling and Henry Harnischfeger, P&H Mining Equipment is today-one of the world's leading suppliers of equipment to the surface mining industry. Based in VVesL Milwaukee, a suburb of Milwaukee, Wisconsin, P&H designs and builds the following equipment: Blast hole drills — powerful machines that apply upwards of 75 tons of pulldown force and high torque rotary power to create uniform grids of "soda-straw" blast holes or "explosives containers" up Lo 22 inches in diameter and 280 feet deep. The blast holes are drilled into hard rock formations, loaded with explosives, and then detonated. The resulting blast effectively fragments the rock body, making it easier lo load and process. Walking draglines — enormous digging machines most often applied to coal and phosphate mines. In coal mines, draglines are used to remove the layers of sub-soil overburden capping coal seams. In Australian and Wyoming coal mines, this overburden can be upwards of 280 feet thick. The biggest draglines have booms longer than a football field and dig with buckets large enough to hold four mini-vans with room Lo spare. Electric shovels — large digging machines applied to loading material into haul Lrucks at surface mines. The biggest shovels have dippers that can move over 100 tons in one "bite." The biggest trucks used in Loday's surface mines can handle up to 400 Ions in the box (the tires on these monster trucks measure 14 feel from the ground Lo the top of the tire rim). Electric shovels dig minerals such as coal, copper ore, gold ore, iron ore, and oil sands at surface mines around Lhe world. Why are mining machines so large? In a word, it comes down to the economics of the modern mining industry. With over six billion minerals consumers, lhe mining industry must utilize the most efficient, lowest-cost-per-ton tools and processes to extract needed minerals from the earth's crust. Every person in the United States utilizes about 40,000 pounds of minerals each year. Of that total, about 9,000 pounds are applied to construction of roads, dams, bridges, and other infrasLruclures. The resL of the minerals are applied to energy (coal, petroleum and natural gas), automobiles, aircraft, appliances, computers, medicines, health care, defense, building materials, and much more. In developing nations, the annual minerals consumption rate is far less than that of the U.S., but it is growing. As a result, the mining industry will continue to grow to meet demand. Significantly, the industry is now applying enlightened policies and techniques to get the minerals we need with minimal impact on the environment. Our global civilization is built, literally, on Lhe resources we can obtain from the earth's crust. As lhe mining industry puts il, "If it isn't grown, it has to be mined." At a coal mine in Eastern Australia, a P&H 9020 walking dragline removes layers ot limestone overburden capping a coal seam. In the background just to the left of the dragline's vertical "mast" is a P&H 250XP diesel drill setting up a grid of blast holes for the next blast that will fragment the limestone. At a diamond mine in Southern Africa, a P&H 250XP-ST diesel blast hole drill creates blast holes in ultra-hard basaltic rock. |