Creative Woodworks & crafts 2003-04, страница 18

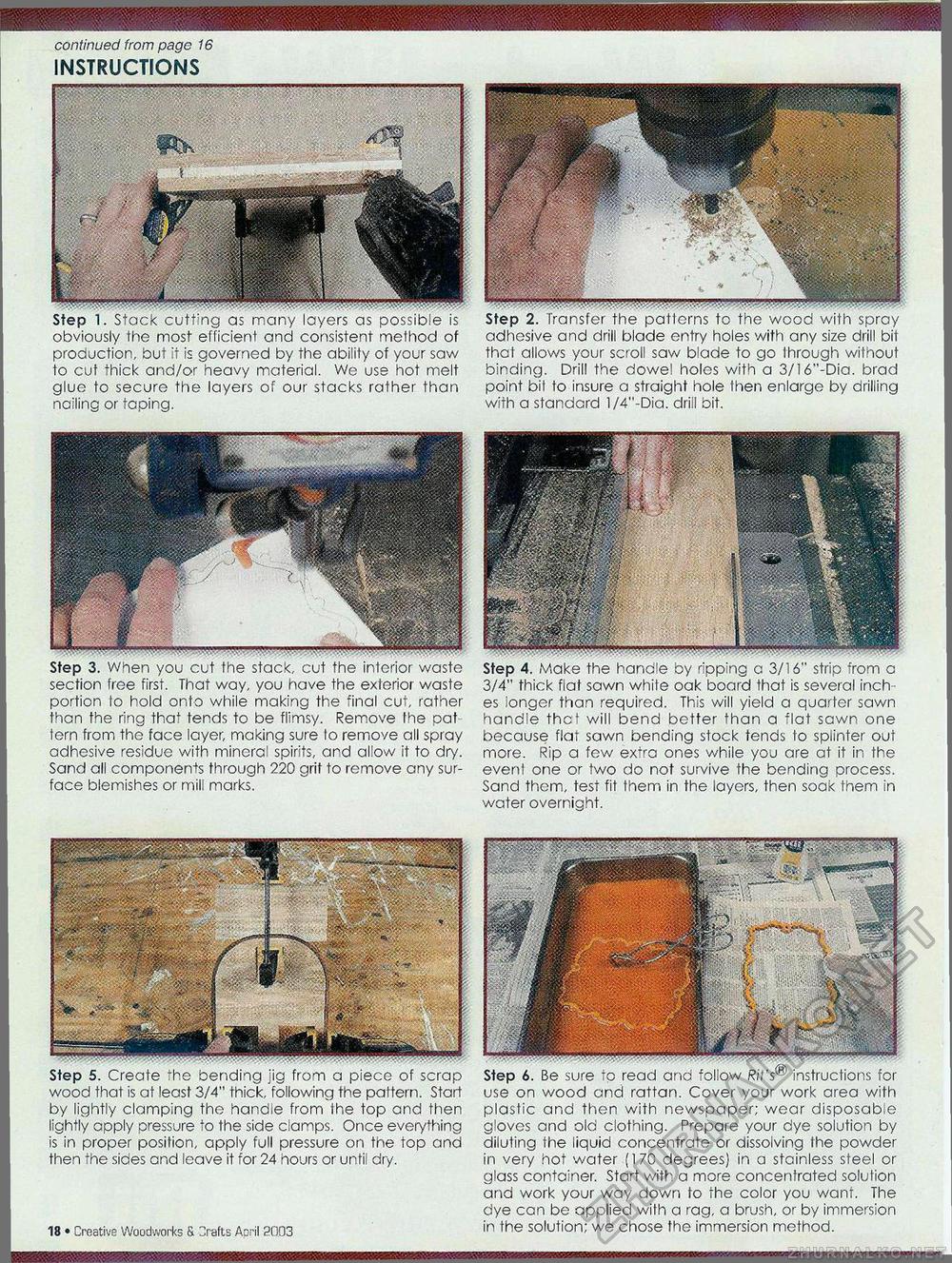

adhesive and drill blade entry holes with any size drill bit that allows your scroll saw blade to go through without binding. Drill the dowel holes with a 3/16"-Dia. brad point bil to insure a straight hole then enlarge by drilling with a standard l/4"-Dia. drill bit. Step 4. Make the handle by ripping a 3/16" strip from c 3/4" thick flat sawn white oak board that is several inch es longer than required. This will yield a quarter sawn handle thct will bend better than a flat sawn one because flat sawn bending stock tends to splinter out more. Rip a few extra ones while you are at it in the event one or two do not survive the bending process. Sand them, test fit Ihem in the layers, then soak them in water overnight. continued from page 16 INSTRUCTIONS obviously the most efficient and consistent method of production, but it is governed by the ability of your saw to cut thick and/or heavy material. We use hot melt glue to secure the layers of our stacks rather than nailing or taping. section free first. That way, you have the exterior waste portion to hold onto while making the final cut, rather than the ring that tends to be flimsy. Remove the pat tern from the face layer, making sure lo remove all spray adhesive residue with minora' spirits, ard allow it to dry. Sand all components through 220 grit to remove any surface blemishes or mill marks. Step 5. Create ^he bending jig from a piece of scrap wood that is at least 3/4" thick, following the pattern. Start by lightly clamping the handle from the top and then lightly apply pressure to the side clamps. Once everything is in proper position, apply full pressure on the top and then the sides and leave it for 24 hours or until dry. Creative Woodworks S. Crafts April 2003 • 19 Step 6. Be sure to read and follow R/7's® instructions for use on wood and rattan. Cover your work area with plastic and then with newspaper; wear disposable gloves and old clothing. Prepare your dye solution by diluting the liquid concentrate or dissolving the powder in very hot water (170 degrees) in a stainless steel or glass container. Start with a more concentrated solution and work your way down to the color you want. The dye can be applied wilh a rag, a brush, or by immersion in the solution; we chose the immersion method. |