Creative Woodworks & crafts 2004-06, страница 18

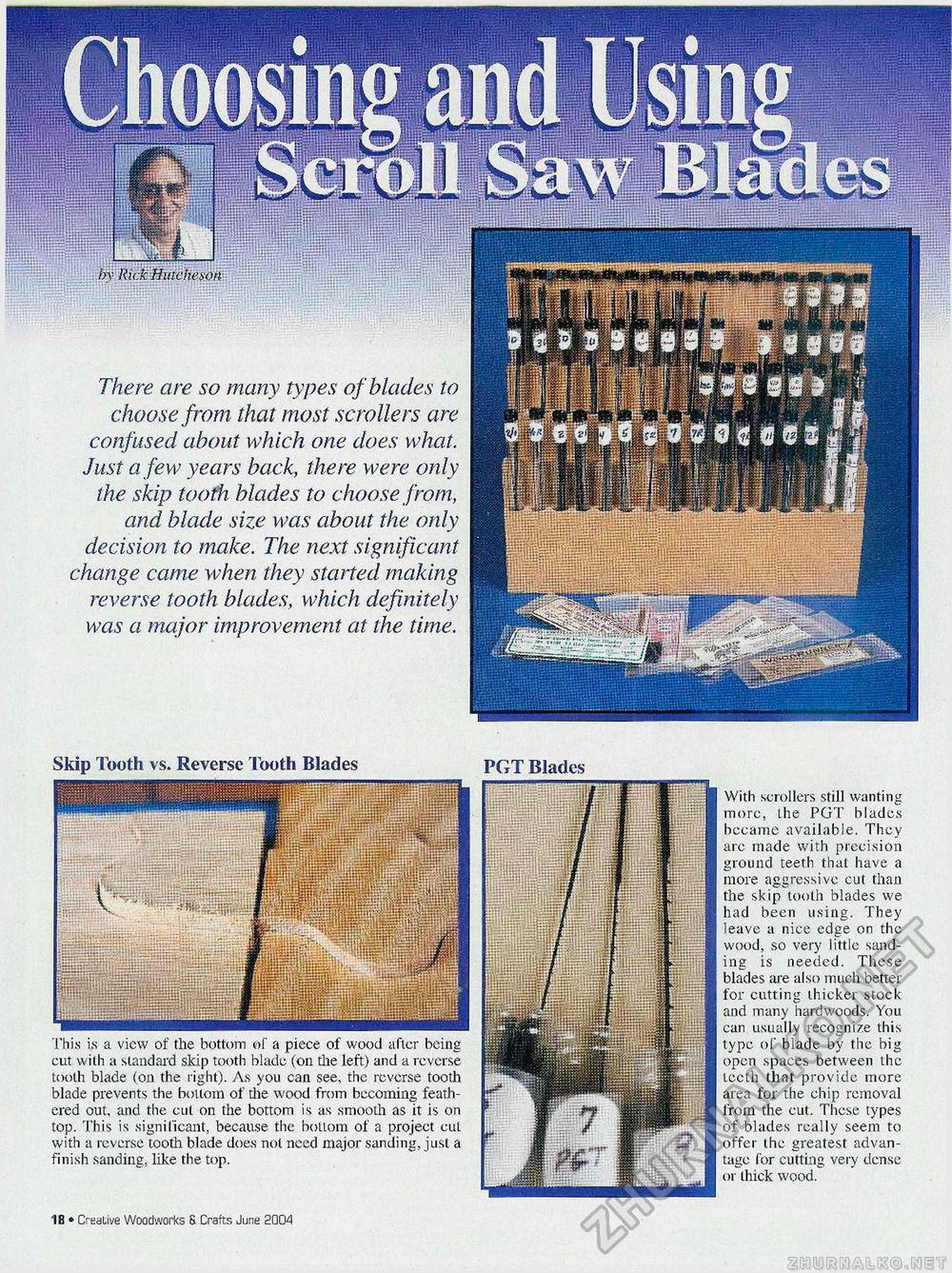

There are so many types of blades to choose from that most scrollers are confused about which one does what. Just a few years back, there were only the skip tooth blades to choose from, and blade size was about the only decision to make. The next significant change came when they started making reverse tooth blades, which definitely was a major improvement at the time. Skip Tooth vs. Reverse Tooth Blades PGT Blades This is a view of the bottom of a piece of wood after being cut with a standard skip tooth blade (on the left) and a reverse tooth blade (on the right). As you can see. the reverse tooth blade prevents the bottom of die wood from becoming feathered out, and the cut on the bottom is as smooth as it is on top. This is significant, because the bottom of a project cut with a reverse tooth blade does not need major sanding, just a finish sanding, like the top. With scrollers still wanting more, the PGT blades became available. They are made with precision ground teeth that have a more aggressive cut than the skip tooth blades we had been using. They leave a nice edge on the wood, so very little sanding is needed. These blades are also much better for cutting thicker stock and many hardwoods. You can usually recognize this type of blade by the big open spaces between the tecih that provide more area for the chip removal from the cut. These types of blades really seem to offer the greatest advantage for cutting very dense or thick wood. 18 • Creative Woodwork?; & Crafts June 2004 |