Creative Woodworks & crafts 2005-09, страница 76

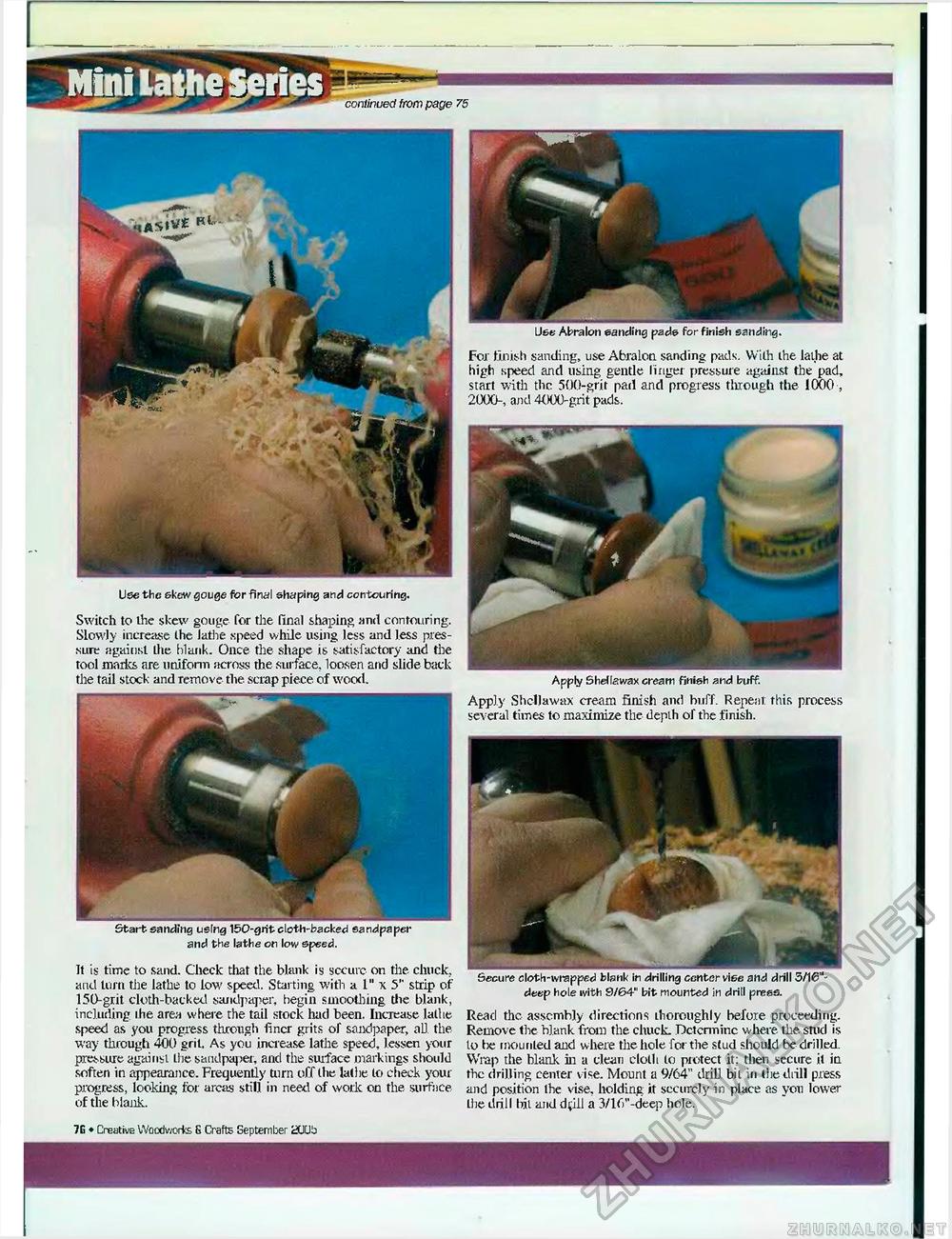

continued from page 75 Use Abralon eanding pads for finish sanding. For finish sanding, use A bra Ion sanding pads. With the lathe at high speed and using gentle linger pressure against the pad, start with the 500-grit pail and progress through the 1000 , 2U00-, and 4000-grit pads.

Apply Shetlawax cream finish and buff. Apply Shetlawax cream finish and buff. Apply ShcDawiix (Team finish and huff. Repeal this process several times to maximize the depth of the finish. Use the skew gouge for final shaping and contouring. Switch to the skew gouge for the final shaping and contouring. Slowly increase the lathe speed while using less and less pies-sure against the blank. Once the shape is satisfactory and the tool marks are uniform across the surface, loosen and slide back the tail stock and remove the scrap piece, of wood. Start sanding using 150-grit cloth-backed sandpaper and the lathe on low speed. It is time to sand. Check that the blank is secure on the. chuck, and turn the lathe to low speed. Starting with a 1" x 5" strip of 150-grit cloth-backed sandpaper, begin smoothing the blank, including ihe area where the tail stock had been. Increase lathe speed as you progress through finer grits of sandpaper, all. the way through 400 grit. As you increase lathe speed, lessen your pressure against the sandpaper, and the surface markings should soften in appearance. Frequently turn off the lathe to cheek your progress, looking for areas still in need of work on the surface of the blank. 7E ♦ Creatine Woodworks G Crafts September 3JUb Secure cloth-wrapped blank in drilling center vise and drill 3/16"-deep hole ivith 9/64" bit mounted in drill press. Read the assembly directions thoroughly before proceeding. Remove the blank from the chuck. Determine where the sftid is to tie mounted and where the hole for the stud should be drilled. Wrap the blank in a clean cloth to protect it; then secure it in the drilling center vise. Mount a 9/64" drill bit in the drill press and position the vise, holding it securely in place as you lower the drill liit and d|;iil a 3/16"-deep hole. |