Creative Woodworks & crafts-103-2004-Holiday, страница 44

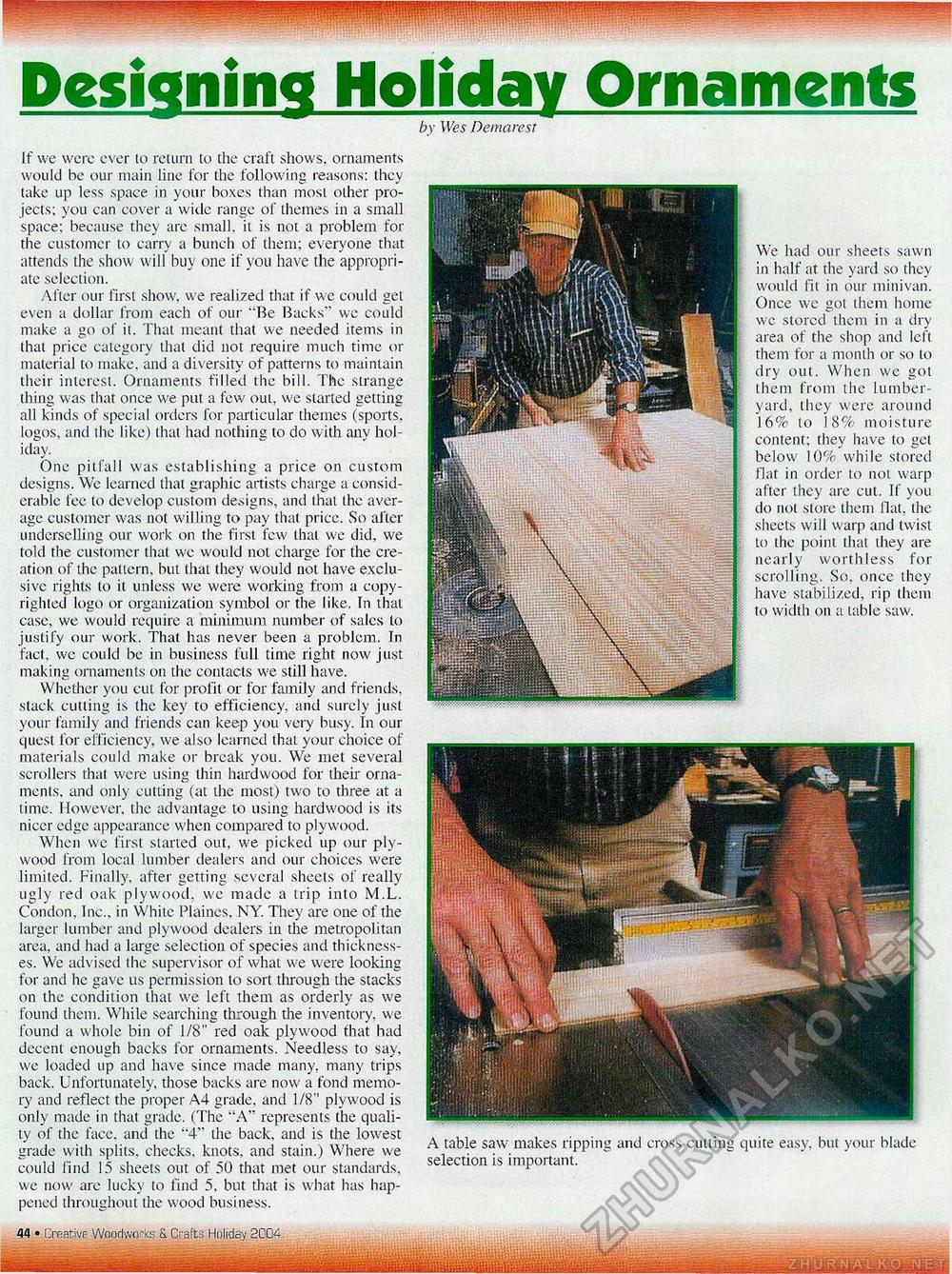

Designing Holiday Ornamentsby Wes Demarest Creative Woodworks & Craft:; Holiday 2004 • 15 If we were ever to return to the craft shows, ornaments would ho our main line for the following reasons: they lake up less space in your boxes than most other projects; you can cover a wide range of themes in a small space; because they arc small, it is not a problem for the customer to carry a bunch of them; everyone that attends the show will buy one if you have the appropriate selection. After our first show, we realized that if we could get even a dollar from each of our "Be Backs" we could make a go of it. That meant that we needed items in that price category that did not require much time or material to make, and a diversity of patterns to maintain their interest. Ornaments filled the bill. The strange thing was that once we put a few out, we started getting all kinds of special orders for particular themes (sports, logos, and the like) that had nothing to do with any holiday. One pitfall was establishing a price on custom designs. We learned that graphic artists charge a considerable fee to develop custom designs, and that the average customer was not willing to pay that price. So after underselling our work on the first few that we did, we told the customer that we would not charge for the creation of the pattern, but that they would not have exclusive rights to it unless we were working from a copyrighted logo or organization symbol or the like. In that case, we would require a minimum number of sales to justify our work. That has never been a problem. In fact, we could be in business full time right now just making ornaments on the contacts we still have. Whether you cut for profit or for family and friends, stack cutting is the key to efficiency, and surely just your family and friends can keep you very busy. In our quest for efficiency, we also learned that your choice of materials could make or break you. We met several scrollers that were using thin hardwood for their ornaments, and only cutting (at the most) two to three at a time. However, the advantage to using hardwood is its nicer edge appearance when compared to plywood. When we first started out. we picked up our plywood from local lumber dealers and our choices were limited. Finally, after getting several sheets of really ugly red oak plywood, we made a trip into M.L. Condon, Inc., in White Plaines. NY. They are one of the larger lumber and plywood dealers in the metropolitan area, and had a large selection of species and thicknesses. We advised the supervisor of what we were looking for and he gave us permission to sort through the stacks on the condition that we left them as orderly as we found them. While searching through the inventory, we found a whole bin of 1/8" red oak plywood that had decent enough backs for ornaments. Needless to say, we loaded up and have since made many, many trips back. Unfortunately, those backs are now a fond memory and reflect the proper A4 grade, and 1/8" plywood is only made in that grade. (The "A" represents the quality of the face, and the "4" the back, and is the lowest grade with splits, checks, knots, and stain.) Where we could find 15 sheets out of 50 that met our standards, we now are lucky to find 5, but that is what has happened throughout the wood business. We had our sheets sawn in half at the yard so they would fit in our minivan. Once we got them home wc stored them in a dry area of the shop and left them for a month or so to dry out. When we got them from the lumberyard. they were around 16% to 18% moisture content; they have to gel below 10% while stored flat in order to not warp after they are cut. If you do not store them flat, the sheets will warp and twist to the point that they are nearly worthless for scrolling. So, once thev have stabilized, rip them to width on a table saw. A table saw makes ripping and cross cutting quite easy, but your blade selection is important. |