Popular Woodworking 2000-10 № 117, страница 17

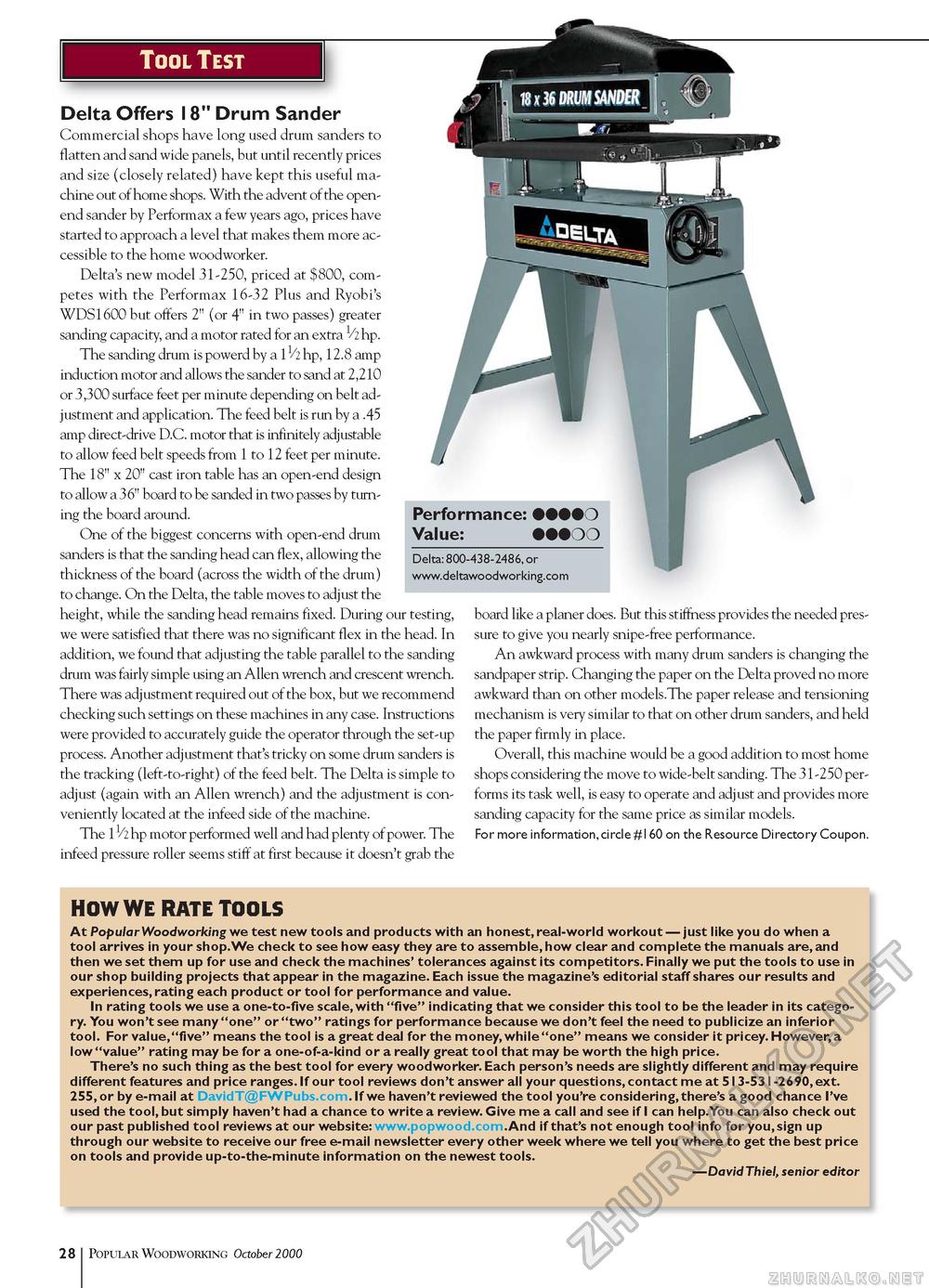

Commercial shops have long used drum sanders to flatten and sand wide panels, but until recently prices and size (closely related) have kept this useful machine out of home shops. With the advent of the open-end sander by Performax a few years ago, prices have started to approach a level that makes them more accessible to the home woodworker. Delta's new model 31-250, priced at $800, competes with the Performax 16-32 Plus and Ryobi's WDS1600 but offers 2" (or 4" in two passes) greater sanding capacity, and a motor rated for an extra 1/2 hp. The sanding drum is powerd by a 11/2 hp, 12.8 amp induction motor and allows the sander to sand at 2,210 or 3,300 surface feet per minute depending on belt adjustment and application. The feed belt is run by a .45 amp direct-drive D.C. motor that is infinitely adjustable to allow feed belt speeds from 1 to 12 feet per minute. The 18" x 20" cast iron table has an open-end design to allow a 36" board to be sanded in two passes by turning the board around. One of the biggest concerns with open-end drum sanders is that the sanding head can flex, allowing the thickness of the board (across the width of the drum) to change. On the Delta, the table moves to adjust the height, while the sanding head remains fixed. During our testing, we were satisfied that there was no significant flex in the head. In addition, we found that adjusting the table parallel to the sanding drum was fairly simple using an Allen wrench and crescent wrench. There was adjustment required out of the box, but we recommend checking such settings on these machines in any case. Instructions were provided to accurately guide the operator through the set-up process. Another adjustment that's tricky on some drum sanders is the tracking (left-to-right) of the feed belt. The Delta is simple to adjust (again with an Allen wrench) and the adjustment is conveniently located at the infeed side of the machine. The 11/2 hp motor performed well and had plenty of power. The infeed pressure roller seems stiff at first because it doesn't grab the Performance: ••••O Value: •••GO Delta: 800-438-2486, or www.deltawoodworking.com board like a planer does. But this stiffness provides the needed pressure to give you nearly snipe-free performance. An awkward process with many drum sanders is changing the sandpaper strip. Changing the paper on the Delta proved no more awkward than on other models.The paper release and tensioning mechanism is very similar to that on other drum sanders, and held the paper firmly in place. Overall, this machine would be a good addition to most home shops considering the move to wide-belt sanding. The 31-250 performs its task well, is easy to operate and adjust and provides more sanding capacity for the same price as similar models. For more information, circle #160 on the Resource Directory Coupon. HOW WE RATE TOOLS At Popular Woodworking we test new tools and products with an honest, real-world workout — just like you do when a tool arrives in your shop.We check to see how easy they are to assemble, how clear and complete the manuals are, and then we set them up for use and check the machines' tolerances against its competitors. Finally we put the tools to use in our shop building projects that appear in the magazine. Each issue the magazine's editorial staff shares our results and experiences, rating each product or tool for performance and value. In rating tools we use a one-to-five scale,with "five" indicating that we consider this tool to be the leader in its category. You won't see many "one" or "two" ratings for performance because we don't feel the need to publicize an inferior tool. For value,"five" means the tool is a great deal for the money,while "one" means we consider it pricey. However,a low "value" rating may be for a one-of-a-kind or a really great tool that may be worth the high price. There's no such thing as the best tool for every woodworker. Each person's needs are slightly different and may require different features and price ranges. If our tool reviews don't answer all your questions, contact me at 513-531-2690, ext. 255, or by e-mail at DavidT@FWPubs.com. If we haven't reviewed the tool you're considering, there's a good chance I've used the tool, but simply haven't had a chance to write a review. Give me a call and see if I can help.You can also check out our past published tool reviews at our website: www.popwood.com.And if that's not enough tool info for you,sign up through our website to receive our free e-mail newsletter every other week where we tell you where to get the best price on tools and provide up-to-the-minute information on the newest tools. —David Thiel, senior editor 12 Popular Woodworking October 2000 |

||||||||||||||||||