Popular Woodworking 2000-11 № 118, страница 13

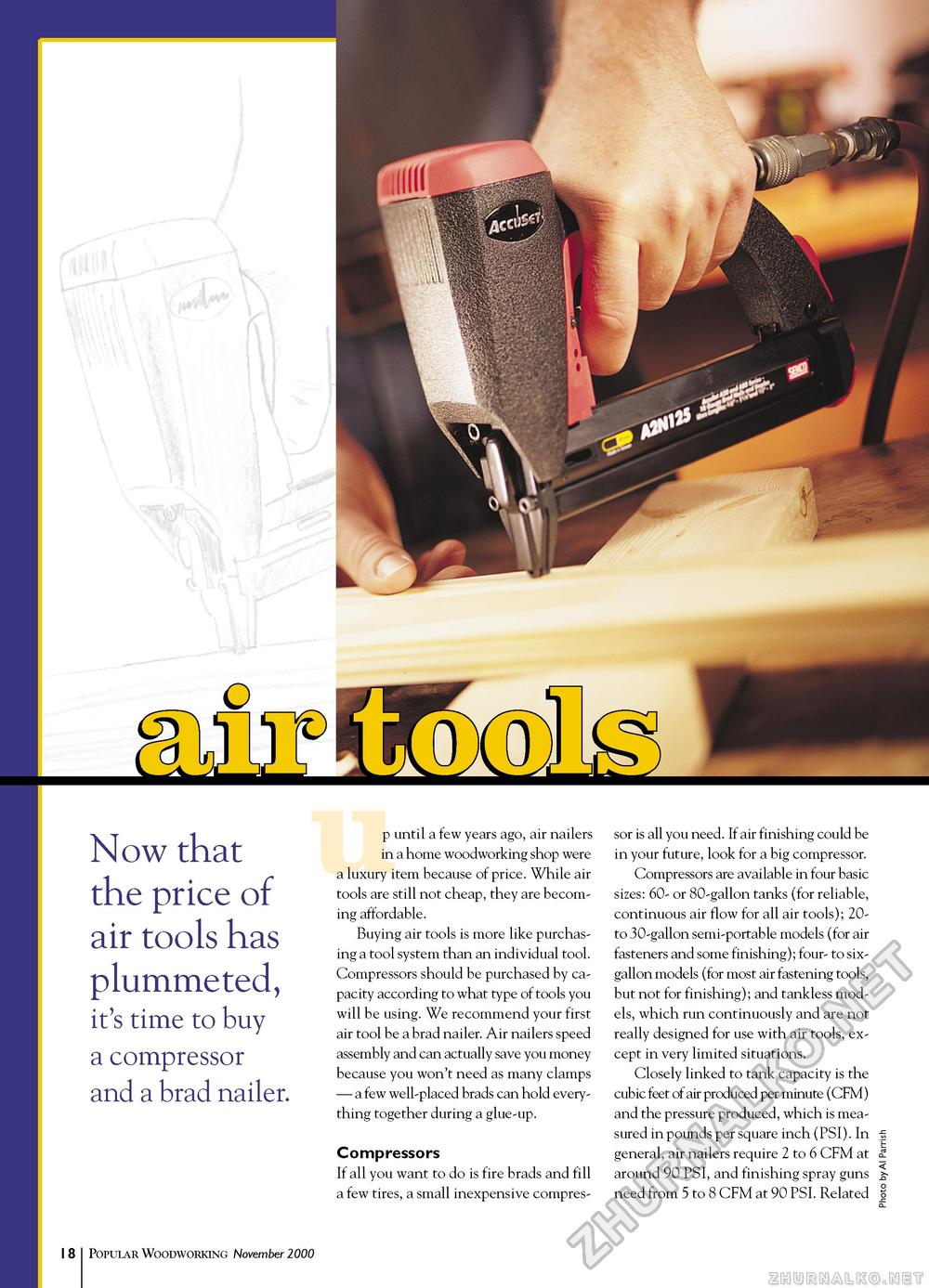

Now that the price of air tools has plummeted, it's time to buy a compressor and a brad nailer. p until a few years ago, air nailers in a home woodworking shop were a luxury item because of price. While air tools are still not cheap, they are becoming affordable. Buying air tools is more like purchasing a tool system than an individual tool. Compressors should be purchased by capacity according to what type of tools you will be using. We recommend your first air tool be a brad nailer. Air nailers speed assembly and can actually save you money because you won't need as many clamps — a few well-placed brads can hold everything together during a glue-up. Compressors If all you want to do is fire brads and fill a few tires, a small inexpensive compres sor is all you need. If air finishing could be in your future, look for a big compressor. Compressors are available in four basic sizes: 60- or 80-gallon tanks (for reliable, continuous air flow for all air tools); 20-to 30-gallon semi-portable models (for air fasteners and some finishing); four- to six-gallon models (for most air fastening tools, but not for finishing); and tankless models, which run continuously and are not really designed for use with air tools, except in very limited situations. Closely linked to tank capacity is the cubic feet of air produced per minute (CFM) and the pressure produced, which is measured in pounds per square inch (PSI). In general, air nailers require 2 to 6 CFM at around 90 PSI, and finishing spray guns need from 5 to 8 CFM at 90 PSI. Related 14 Popular Woodworking November 2000 |