Popular Woodworking 2000-11 № 118, страница 29

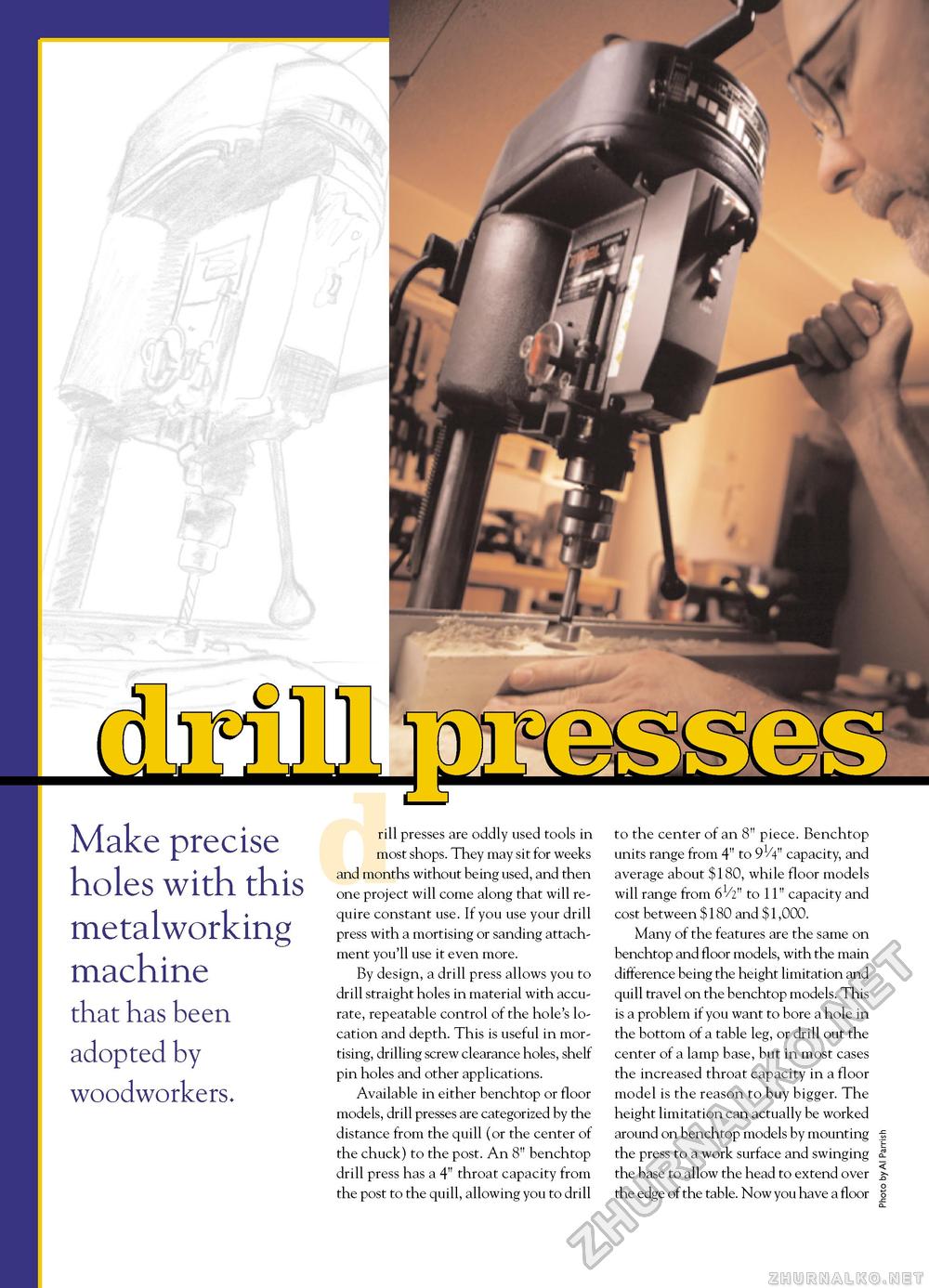

Make precise holes with this metalworking machine that has been adopted by woodworkers. rill presses are oddly used tools in most shops. They may sit for weeks and months without being used, and then one project will come along that will require constant use. If you use your drill press with a mortising or sanding attachment you'll use it even more. By design, a drill press allows you to drill straight holes in material with accurate, repeatable control of the hole's location and depth. This is useful in mortising, drilling screw clearance holes, shelf pin holes and other applications. Available in either benchtop or floor models, drill presses are categorized by the distance from the quill (or the center of the chuck) to the post. An 8" benchtop drill press has a 4" throat capacity from the post to the quill, allowing you to drill to the center of an 8" piece. Benchtop units range from 4" to 91/4" capacity, and average about $180, while floor models will range from 61/2" to 11" capacity and cost between $180 and $1,000. Many of the features are the same on benchtop and floor models, with the main difference being the height limitation and quill travel on the benchtop models. This is a problem if you want to bore a hole in the bottom of a table leg, or drill out the center of a lamp base, but in most cases the increased throat capacity in a floor model is the reason to buy bigger. The height limitation can actually be worked around on benchtop models by mounting the press to a work surface and swinging the base to allow the head to extend over the edge of the table. Now you have a floor |