Popular Woodworking 2000-11 № 118, страница 51

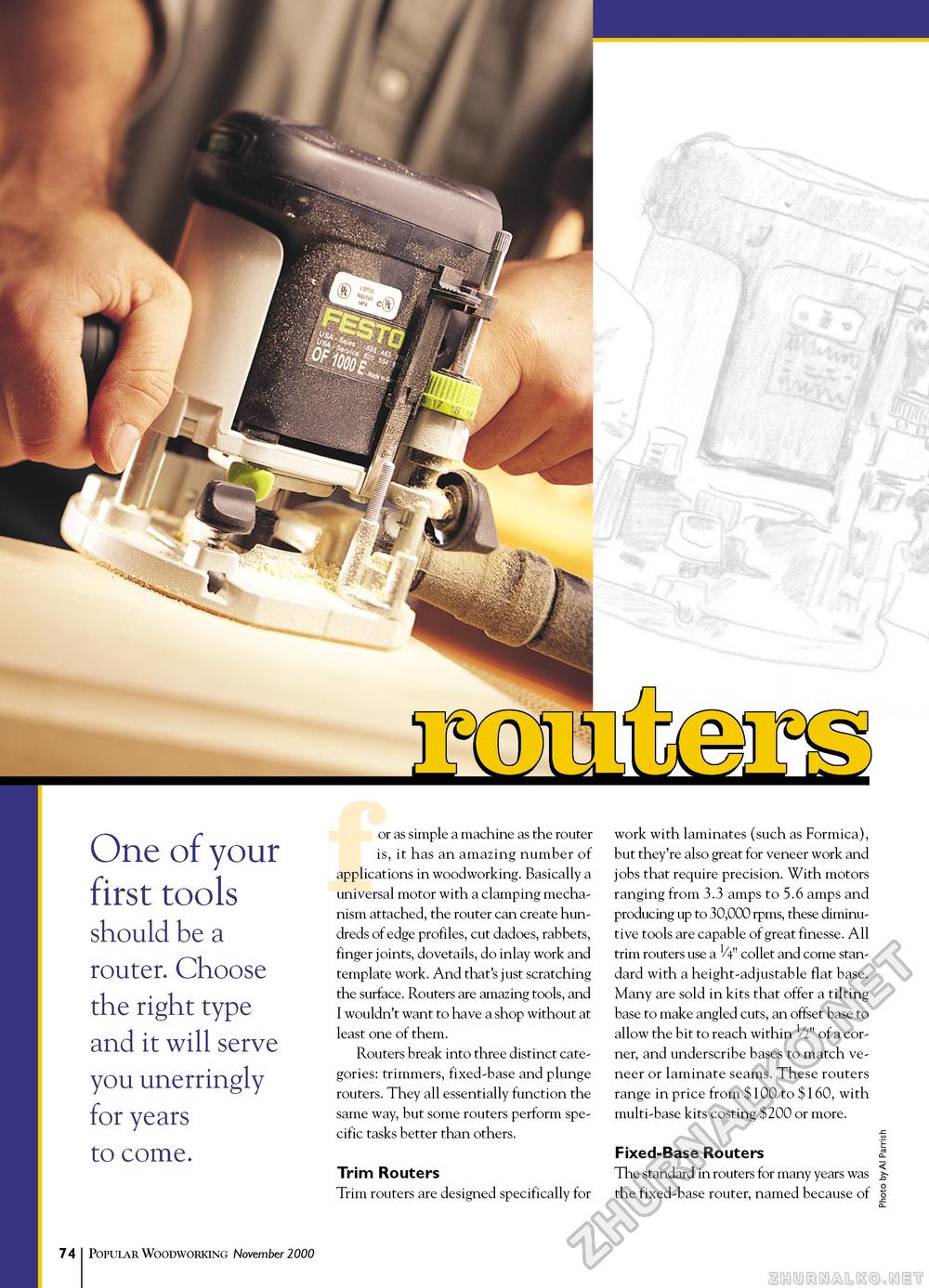

One of your first tools should be a router. Choose the right type and it will serve you unerringly for years to come. or as simple a machine as the router is, it has an amazing number of applications in woodworking. Basically a universal motor with a clamping mechanism attached, the router can create hundreds of edge profiles, cut dadoes, rabbets, finger joints, dovetails, do inlay work and template work. And that's just scratching the surface. Routers are amazing tools, and I wouldn't want to have a shop without at least one of them. Routers break into three distinct categories: trimmers, fixed-base and plunge routers. They all essentially function the same way, but some routers perform specific tasks better than others. Trim Routers Trim routers are designed specifically for work with laminates (such as Formica), but they're also great for veneer work and jobs that require precision. With motors ranging from 3.3 amps to 5.6 amps and producing up to 30,000 rpms, these diminutive tools are capable of great finesse. All trim routers use a 1/4" collet and come standard with a height-adjustable flat base. Many are sold in kits that offer a tilting base to make angled cuts, an offset base to allow the bit to reach within V2" of a corner, and underscribe bases to match veneer or laminate seams. These routers range in price from $100 to $160, with multi-base kits costing $200 or more. Fixed-Base Routers The standard in routers for many years was the fixed-base router, named because of 14 Popular Woodworking November 2000 |