Popular Woodworking 2001-10 № 124, страница 48

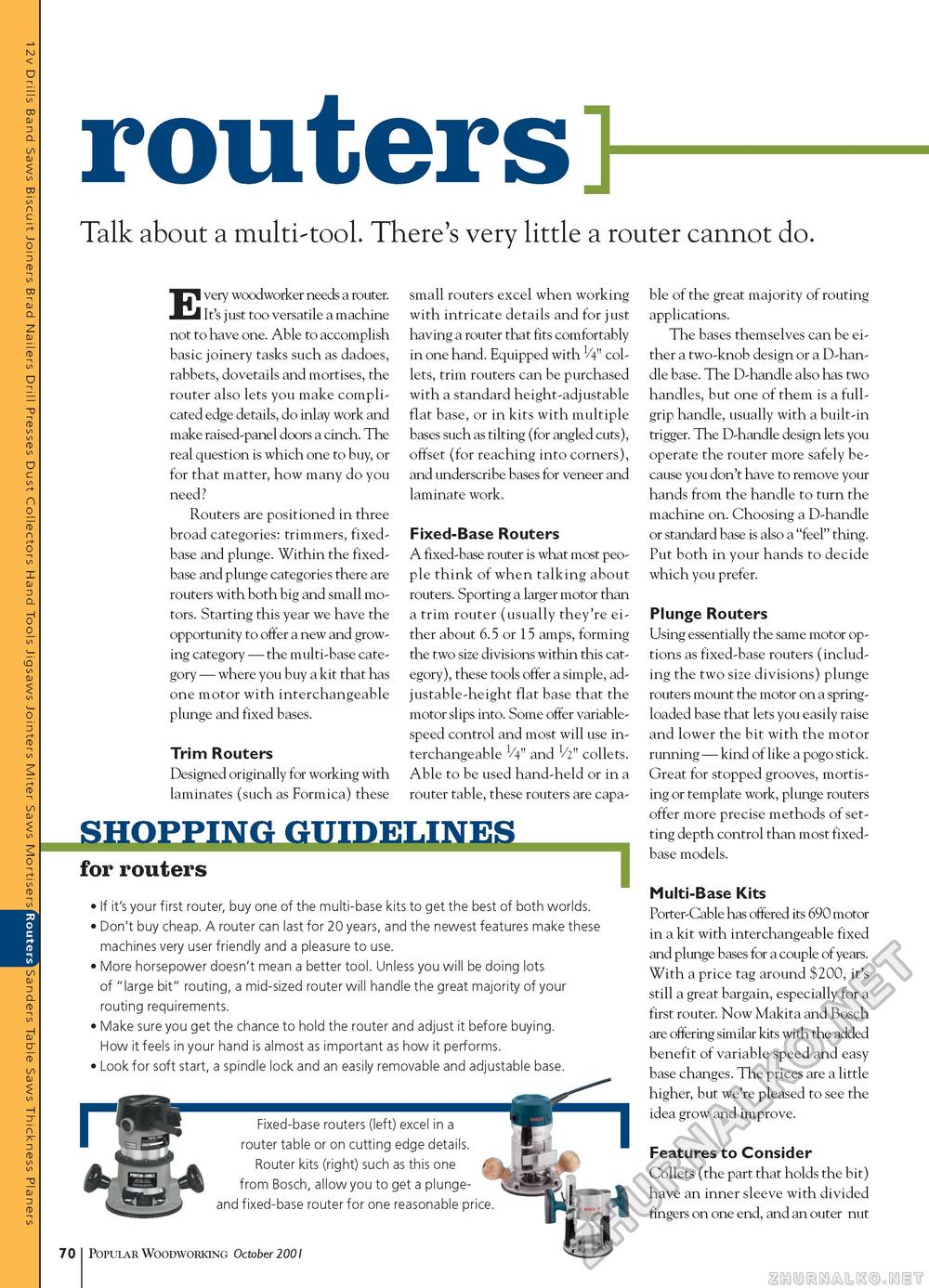

routers ]-Talk about a multi-tool. There's very little a router cannot do.Every woodworker needs a router. It's just too versatile a machine not to have one. Able to accomplish basic joinery tasks such as dadoes, rabbets, dovetails and mortises, the router also lets you make complicated edge details, do inlay work and make raised-panel doors a cinch. The real question is which one to buy, or for that matter, how many do you need? Routers are positioned in three broad categories: trimmers, fixed-base and plunge. Within the fixed-base and plunge categories there are routers with both big and small motors. Starting this year we have the opportunity to offer a new and growing category — the multi-base category — where you buy a kit that has one motor with interchangeable plunge and fixed bases. Trim Routers Designed originally for working with laminates (such as Formica) these small routers excel when working with intricate details and for just having a router that fits comfortably in one hand. Equipped with V4" collets, trim routers can be purchased with a standard height-adjustable flat base, or in kits with multiple bases such as tilting (for angled cuts), offset (for reaching into corners), and underscribe bases for veneer and laminate work. Fixed-Base Routers A fixed-base router is what most people think of when talking about routers. Sporting a larger motor than a trim router (usually they're either about 6.5 or 15 amps, forming the two size divisions within this category), these tools offer a simple, adjustable-height flat base that the motor slips into. Some offer variable-speed control and most will use interchangeable V4" and Vz" collets. Able to be used hand-held or in a router table, these routers are capa for routers • If it's your first router, buy one of the multi-base kits to get the best of both worlds. • Don't buy cheap. A router can last for 20 years, and the newest features make these machines very user friendly and a pleasure to use. • More horsepower doesn't mean a better tool. Unless you will be doing lots of "large bit" routing, a mid-sized router will handle the great majority of your routing requirements. • Make sure you get the chance to hold the router and adjust it before buying. How it feels in your hand is almost as important as how it performs. • Look for soft start, a spindle lock and an easily removable and adjustable base. Fixed-base routers (left) excel in a router table or on cutting edge details. Router kits (right) such as this one ' from Bosch, allowyou to get a plunge-and fixed-base router for one reasonable price. 10 Popular Woodworking October 2001 ble of the great majority of routing applications. The bases themselves can be either a two-knob design or a D-han-dle base. The D-handle also has two handles, but one of them is a full-grip handle, usually with a built-in trigger. The D-handle design lets you operate the router more safely because you don't have to remove your hands from the handle to turn the machine on. Choosing a D-handle or standard base is also a "feel" thing. Put both in your hands to decide which you prefer. Plunge Routers Using essentially the same motor options as fixed-base routers (including the two size divisions) plunge routers mount the motor on a spring-loaded base that lets you easily raise and lower the bit with the motor running — kind of like a pogo stick. Great for stopped grooves, mortising or template work, plunge routers offer more precise methods of setting depth control than most fixed-base models. Multi-Base Kits Porter-Cable has offered its 690 motor in a kit with interchangeable fixed and plunge bases for a couple of years. With a price tag around $200, it's still a great bargain, especially for a first router. Now Makita and Bosch are offering similar kits with the added benefit of variable speed and easy base changes. The prices are a little higher, but we're pleased to see the idea grow and improve. Features to Consider Collets (the part that holds the bit) have an inner sleeve with divided fingers on one end, and an outer nut |