Popular Woodworking 2001-12 № 125, страница 8

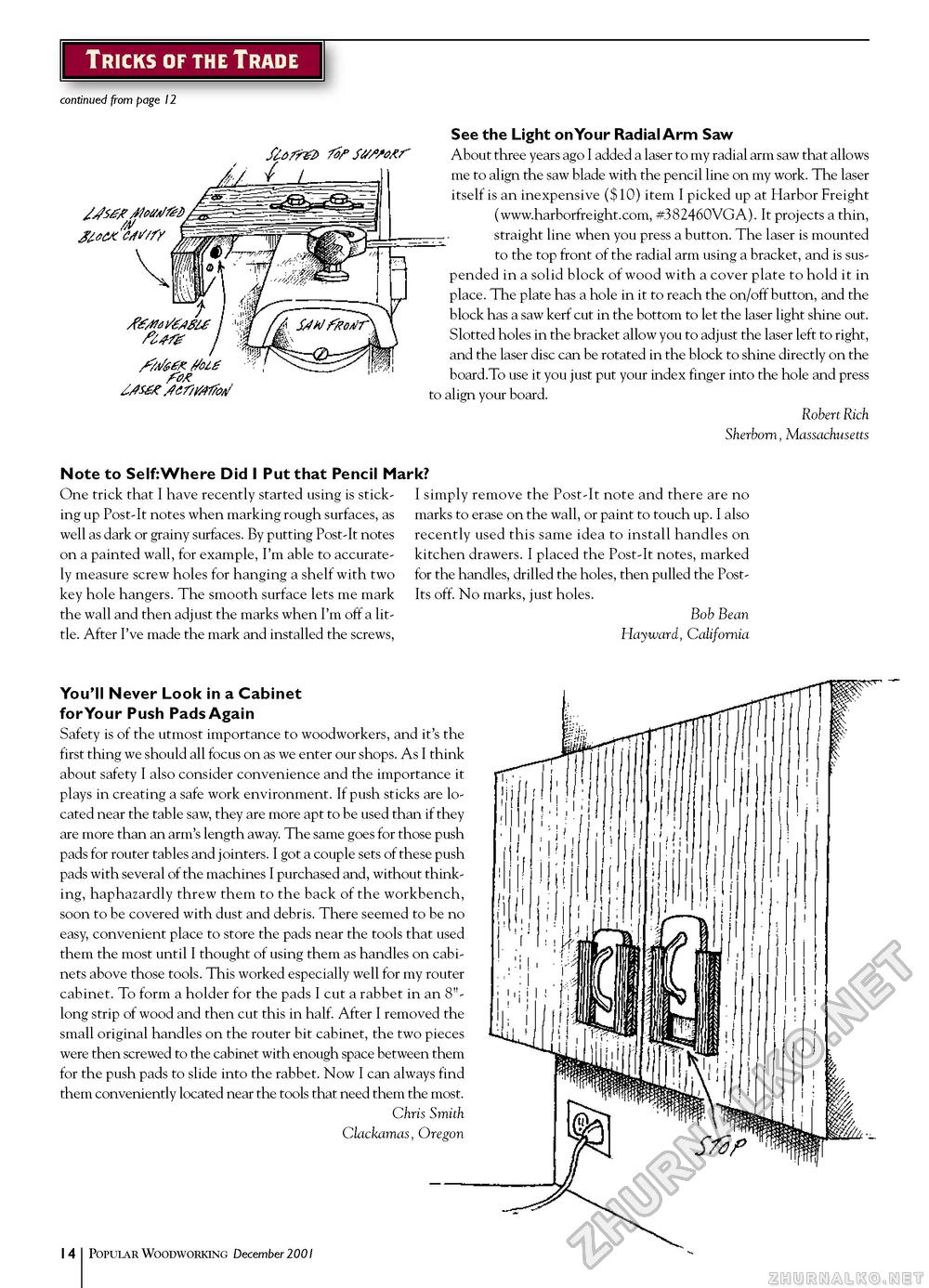

Tricks of the Trade continued from page 12 furr& fSfSWMr' 4 , fa* See the Light on Your Radial Arm Saw About three years ago I added a laser to my radial arm saw that allows me to align the saw blade with the pencil line on my work. The laser itself is an inexpensive ($10) item I picked up at Harbor Freight (www.harborfreight.com, #382460VGA). It projects a thin, straight line when you press a button. The laser is mounted to the top front of the radial arm using a bracket, and is suspended in a solid block of wood with a cover plate to hold it in place. The plate has a hole in it to reach the on/off button, and the block has a saw kerf cut in the bottom to let the laser light shine out. Slotted holes in the bracket allow you to adjust the laser left to right, and the laser disc can be rotated in the block to shine directly on the board.To use it you just put your index finger into the hole and press to align your board. Robert Rich Sherborn, Massachusetts Note to Self:Where Did I Put that Pencil Mark? One trick that I have recently started using is sticking up Post-It notes when marking rough surfaces, as well as dark or grainy surfaces. By putting Post-It notes on a painted wall, for example, I'm able to accurately measure screw holes for hanging a shelf with two key hole hangers. The smooth surface lets me mark the wall and then adjust the marks when I'm off a little. After I've made the mark and installed the screws, I simply remove the Post-It note and there are no marks to erase on the wall, or paint to touch up. I also recently used this same idea to install handles on kitchen drawers. I placed the Post-It notes, marked for the handles, drilled the holes, then pulled the Post-Its off. No marks, just holes. Bob Bean Hayward, California You'll Never Look in a Cabinet forYour Push Pads Again Safety is of the utmost importance to woodworkers, and it's the first thing we should all focus on as we enter our shops. As I think about safety I also consider convenience and the importance it plays in creating a safe work environment. If push sticks are located near the table saw, they are more apt to be used than if they are more than an arm's length away. The same goes for those push pads for router tables and jointers. I got a couple sets of these push pads with several of the machines I purchased and, without thinking, haphazardly threw them to the back of the workbench, soon to be covered with dust and debris. There seemed to be no easy, convenient place to store the pads near the tools that used them the most until I thought of using them as handles on cabinets above those tools. This worked especially well for my router cabinet. To form a holder for the pads I cut a rabbet in an 8"-long strip of wood and then cut this in half. After I removed the small original handles on the router bit cabinet, the two pieces were then screwed to the cabinet with enough space between them for the push pads to slide into the rabbet. Now I can always find them conveniently located near the tools that need them the most. Chris Smith Clackamas, Oregon 14 Popular Woodworking December 2001 |