Popular Woodworking 2002-10 № 130, страница 45

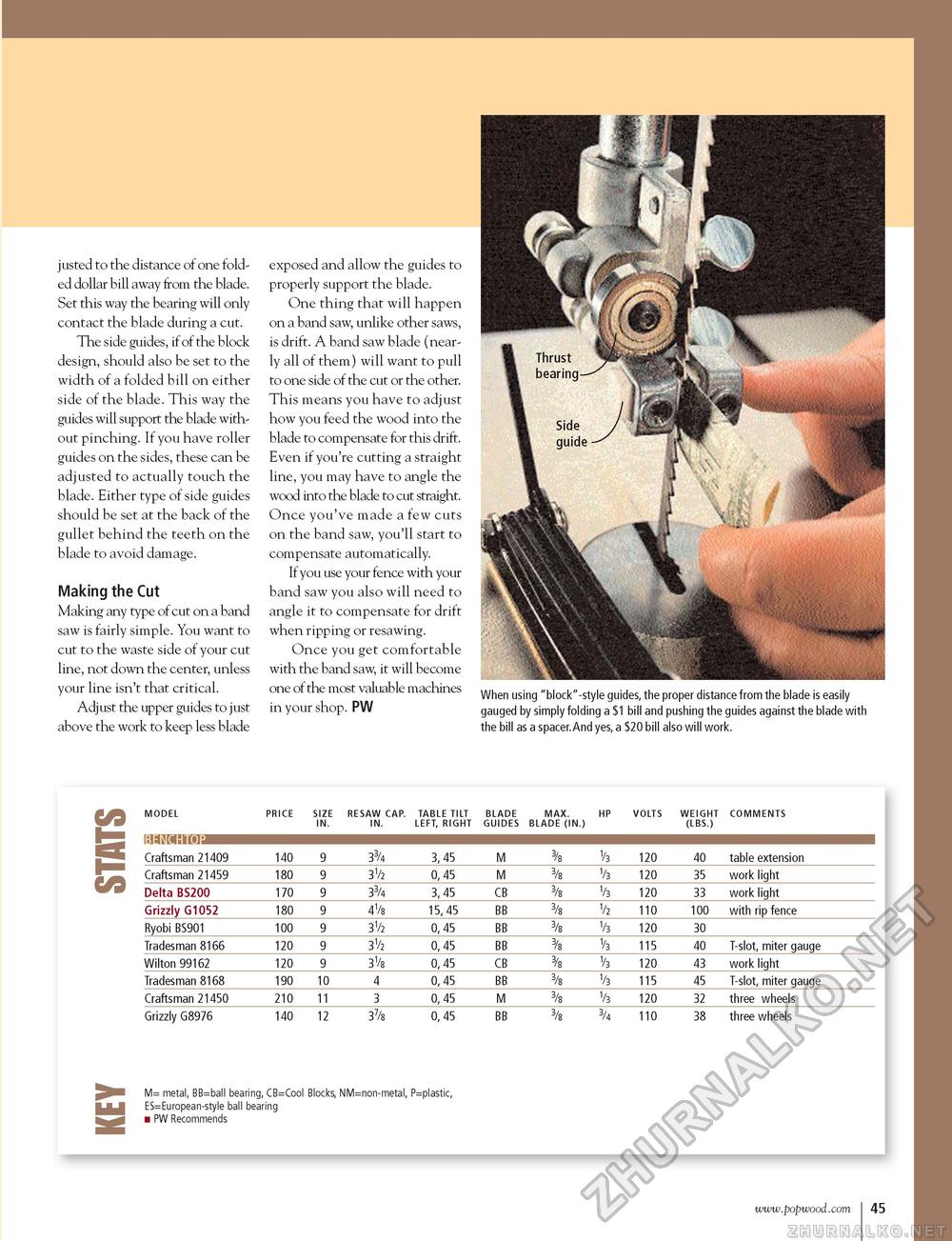

justed to the distance of one folded dollar bill away from the blade. Set this way the bearing will only contact the blade during a cut. The side guides, if of the block design, should also be set to the width of a folded bill on either side of the blade. This way the guides will support the blade without pinching. If you have roller guides on the sides, these can be adjusted to actually touch the blade. Either type of side guides should be set at the back of the gullet behind the teeth on the blade to avoid damage. Making the Cut Making any type of cut on a band saw is fairly simple. You want to cut to the waste side of your cut line, not down the center, unless your line isn't that critical. Adjust the upper guides to just above the work to keep less blade exposed and allow the guides to properly support the blade. One thing that will happen on a band saw, unlike other saws, is drift. A band saw blade (nearly all of them) will want to pull to one side of the cut or the other. This means you have to adjust how you feed the wood into the blade to compensate for this drift. Even if you're cutting a straight line, you may have to angle the wood into the blade to cut straight. Once you've made a few cuts on the band saw, you'll start to compensate automatically. If you use your fence with your band saw you also will need to angle it to compensate for drift when ripping or resawing. Once you get comfortable with the band saw, it will become one of the most valuable machines in your shop. PW When using "block"-style guides, the proper distance from the blade is easily gauged by simply folding a $1 bill and pushing the guides against the blade with the bill as a spacer.And yes, a $20 bill also will work.

M= metal, BB=ball bearing, CB=Cool Blocks, NM=non-metal, P=plastic, ES=European-style ball bearing ■ PW Recommends wujw.popwoood.com 45 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||