Popular Woodworking 2002-10 № 130, страница 76

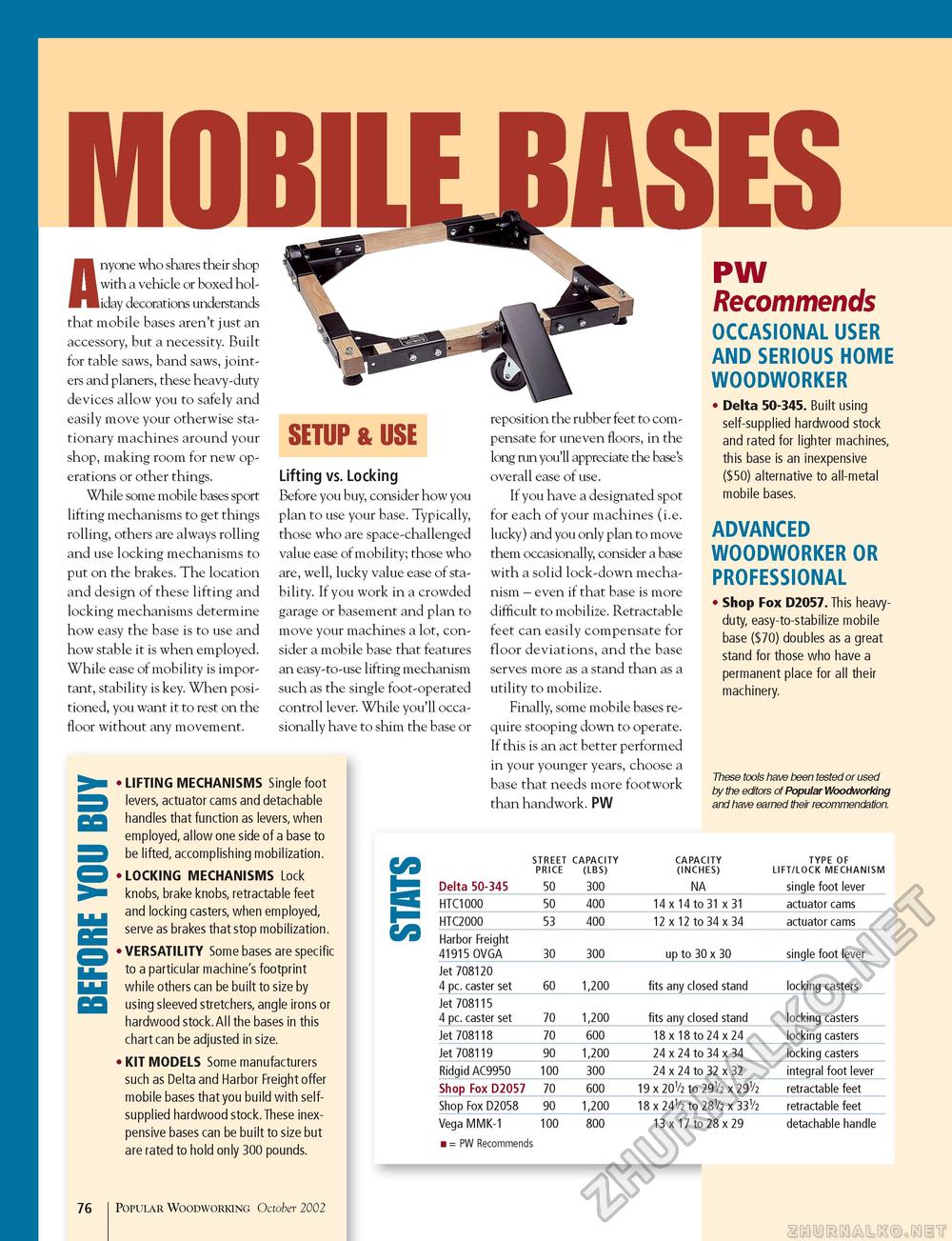

Anyone who shares their shop with a vehicle or boxed holiday decorations understands that mobile bases aren't just an accessory, but a necessity. Built for table saws, band saws, jointers and planers, these heavy-duty devices allow you to safely and easily move your otherwise stationary machines around your shop, making room for new operations or other things. While some mobile bases sport lifting mechanisms to get things rolling, others are always rolling and use locking mechanisms to put on the brakes. The location and design of these lifting and locking mechanisms determine how easy the base is to use and how stable it is when employed. While ease of mobility is important, stability is key. When positioned, you want it to rest on the floor without any movement. SETUP & USE Lifting vs. Locking Before you buy, consider how you plan to use your base. Typically, those who are space-challenged value ease of mobility; those who are, well, lucky value ease of stability. If you work in a crowded garage or basement and plan to move your machines a lot, consider a mobile base that features an easy-to-use lifting mechanism such as the single foot-operated control lever. While you'll occasionally have to shim the base or LIFTING MECHANISMS Single foot levers, actuator cams and detachable handles that function as levers, when employed, allow one side of a base to be lifted, accomplishing mobilization. LOCKING MECHANISMS Lock knobs, brake knobs, retractable feet and locking casters, when employed, serve as brakes that stop mobilization. VERSATILITY Some bases are specific to a particular machine's footprint while others can be built to size by using sleeved stretchers, angle irons or hardwood stock.All the bases in this chart can be adjusted in size. KIT MODELS Some manufacturers such as Delta and Harbor Freight offer mobile bases that you build with self-supplied hardwood stock.These inexpensive bases can be built to size but are rated to hold only 300 pounds. reposition the rubber feet to compensate for uneven floors, in the long run you'll appreciate the base's overall ease of use. If you have a designated spot for each of your machines (i.e. lucky) and you only plan to move them occasionally, consider a base with a solid lock-down mechanism - even if that base is more difficult to mobilize. Retractable feet can easily compensate for floor deviations, and the base serves more as a stand than as a utility to mobilize. Finally, some mobile bases require stooping down to operate. If this is an act better performed in your younger years, choose a base that needs more footwork than handwork. PW PW Recommends OCCASIONAL USER AND SERIOUS HOME WOODWORKER • Delta 50-345. Built using self-supplied hardwood stock and rated for lighter machines, this base is an inexpensive ($50) alternative to all-metal mobile bases. ADVANCED WOODWORKER OR PROFESSIONAL • Shop Fox D2057. This heavy-duty, easy-to-stabilize mobile base ($70) doubles as a great stand for those who have a permanent place for all their machinery. These tools have been tested or used by the editors of Popular Woodworking and have earned their recommendation.

: PW Recommends : PW Recommends 76 Popular Woodworking October 2002 |