Popular Woodworking 2003-04 № 133, страница 15

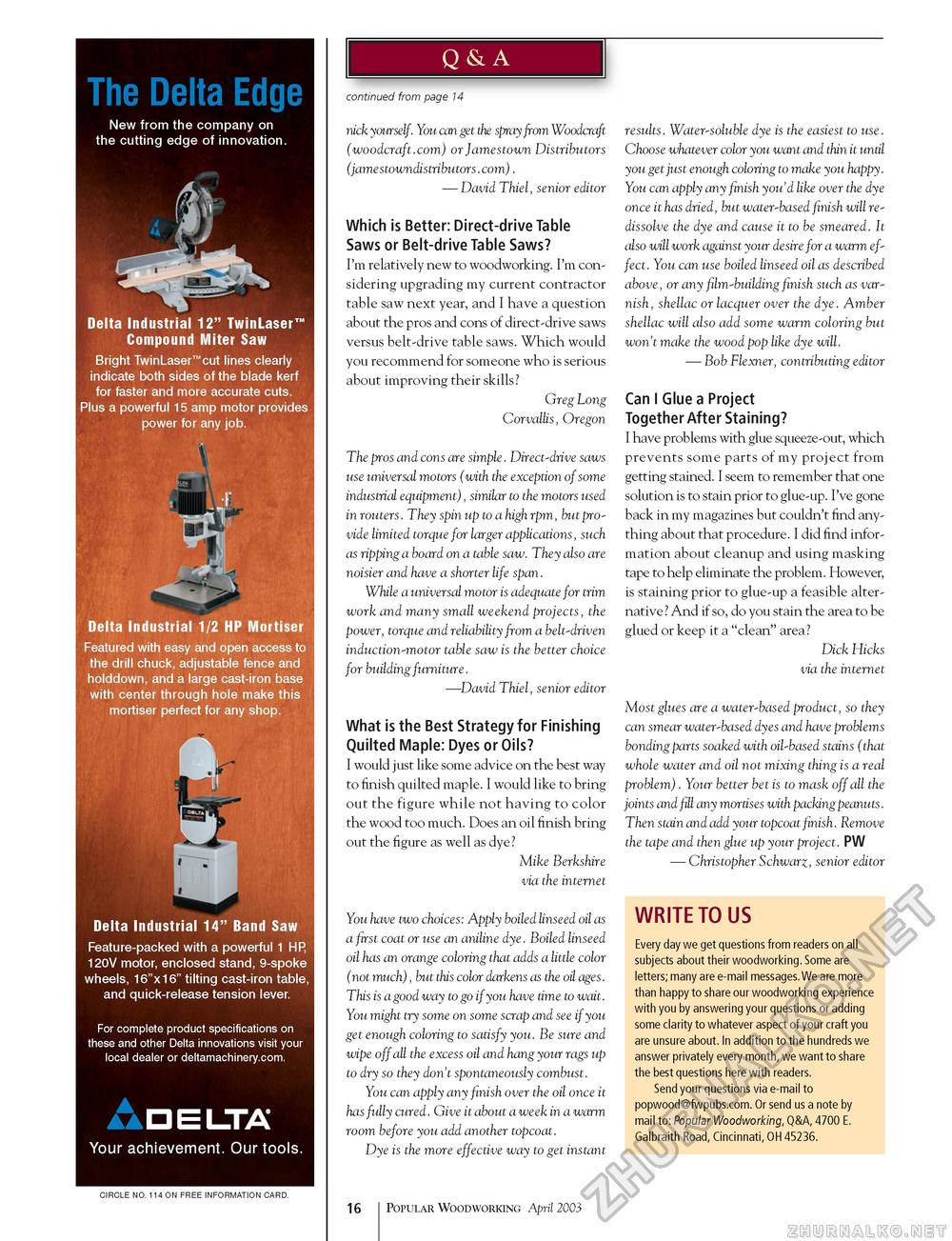

The Delta Edge New from the company on the cutting edge of innovation. Delta Industrial 12" TwinLaser™ Compound Miter Saw Bright TwinLaser™cut lines clearly indicate both sides of the blade kerf for faster and more accurate cuts. Plus a powerful 15 amp motor provides power for any job. Delta Industrial 1/2 HP Mortiser Featured with easy and open access to the drill chuck, adjustable fence and holddown, and a large cast-iron base with center through hole make this mortiser perfect for any shop. Delta Industrial 14" Band Saw Feature-packed with a powerful 1 HP, 120V motor, enclosed stand, 9-spoke wheels, 16"x16" tilting cast-iron table, and quick-release tension lever. For complete product specifications on these and other Delta innovations visit your local dealer or deltamachinery.com. Your achievement. Our tools. Q & A continued from page 14 nick yourself. You can get the spray from Woodcraft (woodcraft.com) or Jamestown Distributors (jamestowndistributors.com). — David Thiel, senior editor Which is Better: Direct-drive Table Saws or Belt-drive Table Saws? I'm relatively new to woodworking. I'm considering upgrading my current contractor table saw next year, and I have a question about the pros and cons of direct-drive saws versus belt-drive table saws. Which would you recommend for someone who is serious about improving their skills? Greg Long Corvallis, Oregon The pros and cons are simple. Direct-drive saws use universal motors (with the exception of some industrial equipment), similar to the motors used in routers. They spin up to a high rpm, butpro-vide limited torque for larger applications, such as ripping a board on a table saw. They also are noisier and have a shorter life span. While a universal motor is adequate for trim work and many small weekend projects, the power, torque and reliability from a belt-driven induction-motor table saw is the better choice for building furniture. —David Thiel, senior editor What is the Best Strategy for Finishing Quilted Maple: Dyes or Oils? I would just like some advice on the best way to finish quilted maple. I would like to bring out the figure while not having to color the wood too much. Does an oil finish bring out the figure as well as dye? Mike Berkshire via the internet You have two choices: Apply boiled linseed oil as a first coat or use an aniline dye. Boiled linseed oil has an orange coloring that adds a little color (not much), but this color darkens as the oil ages. This is a good way to go if you have time to wait. You might try some on some scrap and see if you get enough coloring to satisfy you. Be sure and wipe off all the excess oil and hang your rags up to dry so they don't spontaneously combust. You can apply any finish over the oil once it has fully cured. Give it about a week in a warm room before you add another topcoat. Dye is the more effective way to get instant results. Water-soluble dye is the easiest to use. Choose whatever color you want and thin it until you get just enough coloring to make you happy. You can apply any finish you'd like over the dye once it has dried, but water-based finish will re-dissolve the dye and cause it to be smeared. It also will work against your desire for a warm effect. You can use boiled linseed oil as described above, or any film-building finish such as varnish, shellac or lacquer over the dye. Amber shellac will also add some warm coloring but won't make the wood pop like dye will. — Bob Flexner, contributing editor Can I Glue a Project Together After Staining? I have problems with glue squeeze-out, which prevents some parts of my project from getting stained. I seem to remember that one solution is to stain prior to glue-up. I've gone back in my magazines but couldn't find anything about that procedure. I did find information about cleanup and using masking tape to help eliminate the problem. However, is staining prior to glue-up a feasible alternative? And if so, do you stain the area to be glued or keep it a "clean" area? Dick Hicks via the internet Most glues are a water-based product, so they can smear water-based dyes and have problems bonding parts soaked with oil-based stains (that whole water and oil not mixing thing is a real problem). Your better bet is to mask off all the joints and fill any mortises with packing peanuts. Then stain and add your topcoat finish. Remove the tape and then glue up your project. PW — Christopher Schwarz, senior editor WRITE TO US Every day we get questions from readers on all subjects about their woodworking. Some are letters; many are e-mail messages.We are more than happy to share our woodworking experience with you by answering your questions or adding some clarity to whatever aspect of your craft you are unsure about. In addition to the hundreds we answer privately every month, we want to share the best questions here with readers. Send your questions via e-mail to popwood@fwpubs.com. Or send us a note by mail to: Popular Woodworking, Q&A, 4700 E. Galbraith Road, Cincinnati, OH 45236. CIRCLE NO. 121 ON FREE INFORMATION CARD. 16 Popular Woodworking April 2003 |