Popular Woodworking 2003-10 № 136, страница 18

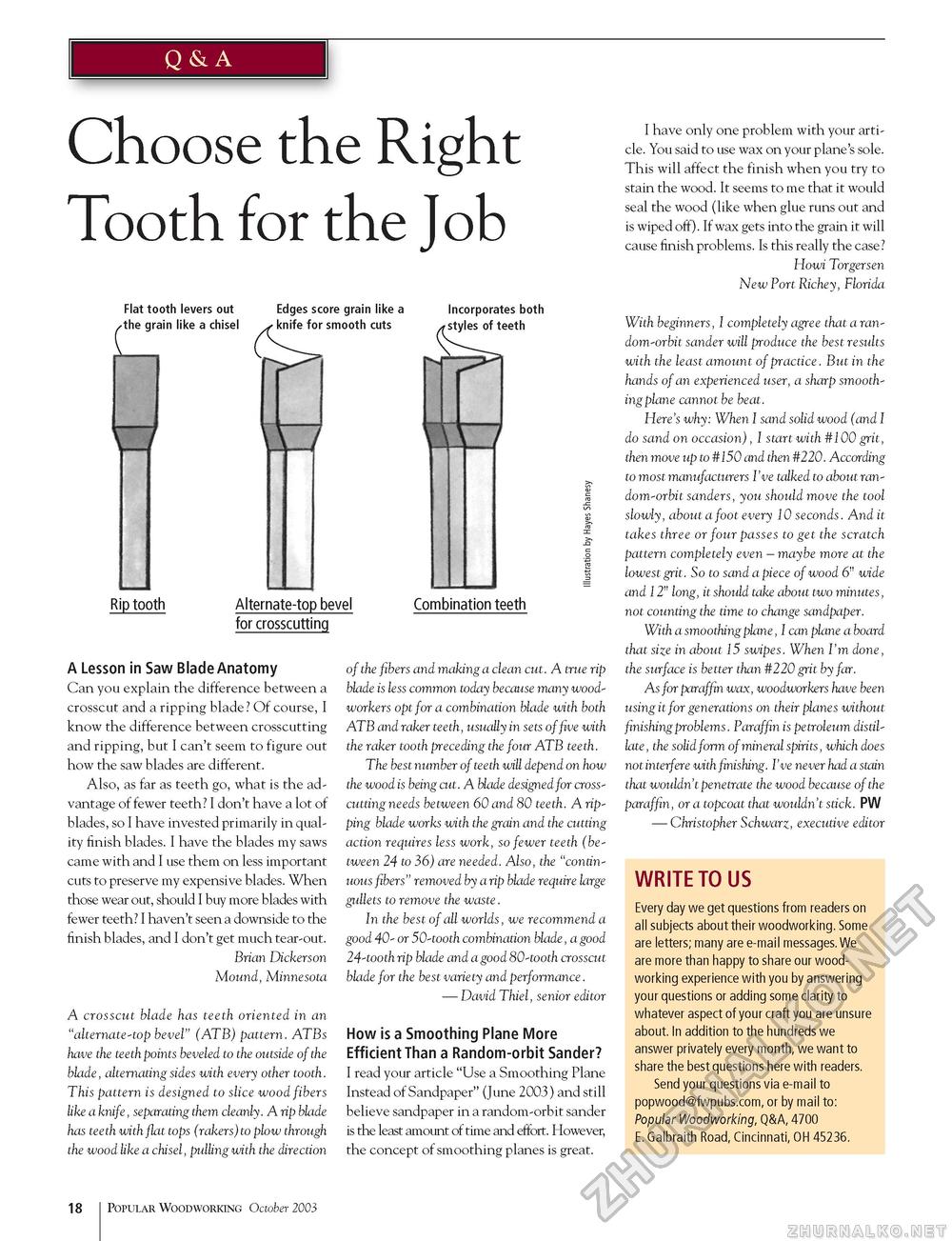

Q & A Choose the Right Tooth for the Job Flat tooth levers out Edges score grain like a ^the grain like a chisel knife for smooth cuts knife for Incorporates both r styles of teeth Rip tooth Alternate-top bevel for crosscutting Combination teeth A Lesson in Saw Blade Anatomy Can you explain the difference between a crosscut and a ripping blade? Of course, I know the difference between crosscutting and ripping, but I can't seem to figure out how the saw blades are different. Also, as far as teeth go, what is the advantage of fewer teeth? I don't have a lot of blades, so I have invested primarily in quality finish blades. I have the blades my saws came with and I use them on less important cuts to preserve my expensive blades. When those wear out, should I buy more blades with fewer teeth? I haven't seen a downside to the finish blades, and I don't get much tear-out. Brian Dickerson Mound, Minnesota A crosscut blade has teeth oriented in an "alternate-top bevel" (ATB) pattern. ATBs have the teeth points beveled to the outside of the blade, alternating sides with every other tooth. This pattern is designed to slice wood fibers like a knife, separating them cleanly. A rip blade has teeth with flat tops (rakers)to plow through the wood like a chisel, pulling with the direction of the fibers and making a clean cut. A true rip blade is less common today because many woodworkers opt for a combination blade with both ATB and raker teeth, usually in sets of five with the raker tooth preceding the four ATB teeth. The best number of teeth will depend on how the wood is being cut. A blade designed for cross-cutting needs between 60 and 80 teeth. A ripping blade works with the grain and the cutting action requires less work, so fewer teeth (between 24 to 36) are needed. Also, the "continuous fibers" removed by a rip blade require large gullets to remove the waste. In the best of all worlds, we recommend a good 40- or 50-tooth combination blade, a good 24-tooth rip blade and a good 80-tooth crosscut blade for the best variety and performance. — David Thiel, senior editor How is a Smoothing Plane More Efficient Than a Random-orbit Sander? I read your article "Use a Smoothing Plane Instead of Sandpaper" (June 2003) and still believe sandpaper in a random-orbit sander is the least amount of time and effort. However, the concept of smoothing planes is great. I have only one problem with your article. You said to use wax on your plane's sole. This will affect the finish when you try to stain the wood. It seems to me that it would seal the wood (like when glue runs out and is wiped off). If wax gets into the grain it will cause finish problems. Is this really the case? Howi Torgersen New Port Richey, Florida With beginners, I completely agree that a random-orbit sander will produce the best results with the least amount of practice. But in the hands of an experienced user, a sharp smoothing plane cannot be beat. Here's why: When I sand solid wood (and I do sand on occasion), I start with #100 grit, then move up to #150 and then #220. According to most manufacturers I've talked to about random-orbit sanders, you should move the tool slowly, about a foot every 10 seconds. And it takes three or four passes to get the scratch pattern completely even - maybe more at the lowest grit. So to sand a piece of wood 6" wide and 12" long, it should take about two minutes, not counting the time to change sandpaper. With a smoothing plane, I can plane a board that size in about 15 swipes. When I'm done, the surface is better than #220 grit by far. As for paraffin wax, woodworkers have been using it for generations on their planes without finishing problems. Paraffin is petroleum distillate, the solid form of mineral spirits, which does not interfere with finishing. I've never had a stain that wouldn't penetrate the wood because of the paraffin, or a topcoat that wouldn't stick. PW — Christopher Schwarz, executive editor WRITE TO US Every day we get questions from readers on all subjects about their woodworking. Some are letters; many are e-mail messages.We are more than happy to share our woodworking experience with you by answering your questions or adding some clarity to whatever aspect of your craft you are unsure about. In addition to the hundreds we answer privately every month, we want to share the best questions here with readers. Send your questions via e-mail to popwood@fwpubs.com, or by mail to: Popular Woodworking, Q&A, 4700 E. Galbraith Road, Cincinnati, OH 45236. 18 Popular Woodworking October 2003 |