Popular Woodworking 2003-10 № 136, страница 24

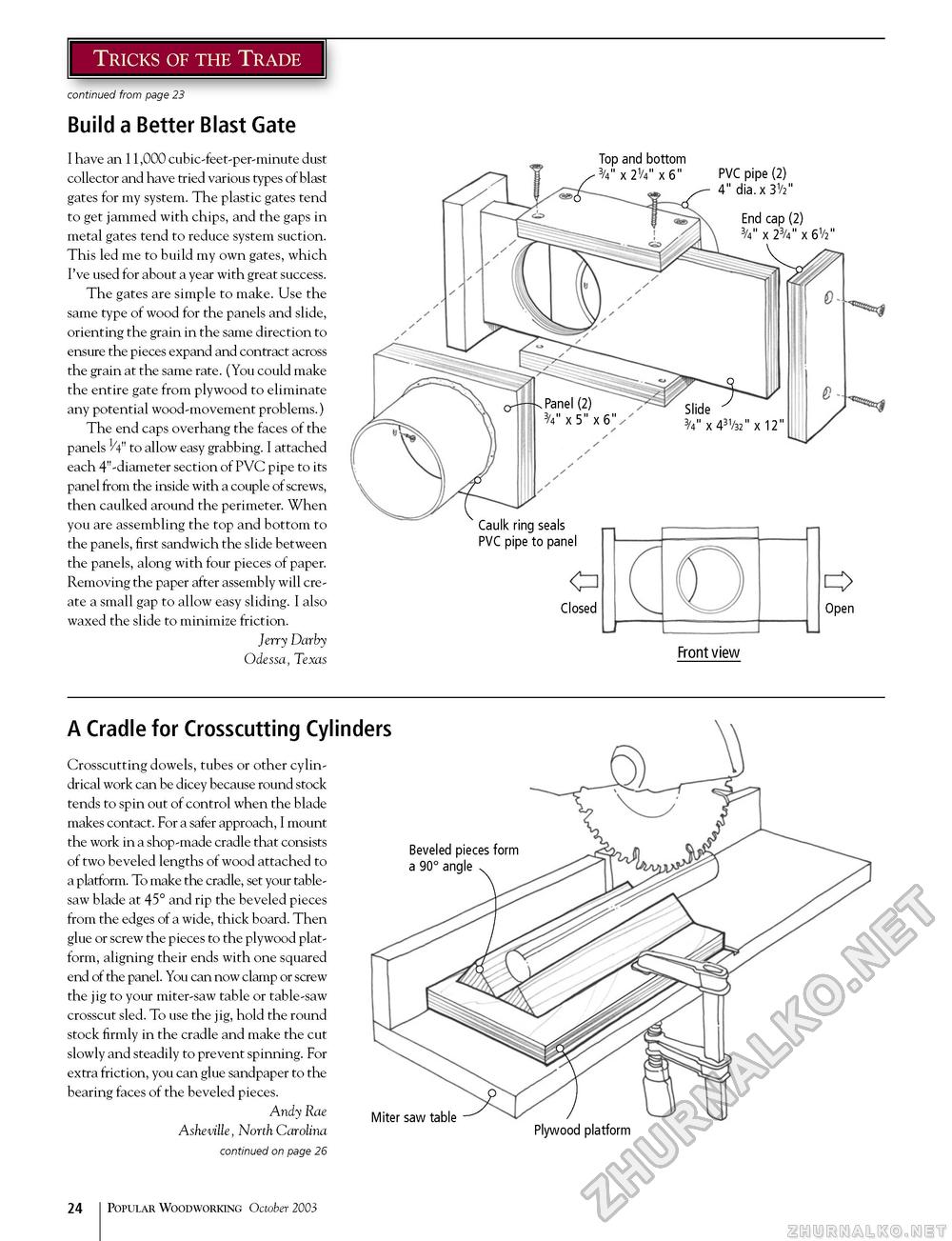

Build a Better Blast Gate I have an 11,000 cubic-feet-per-minute dust collector and have tried various types of blast gates for my system. The plastic gates tend to get jammed with chips, and the gaps in metal gates tend to reduce system suction. This led me to build my own gates, which I've used for about a year with great success. The gates are simple to make. Use the same type of wood for the panels and slide, orienting the grain in the same direction to ensure the pieces expand and contract across the grain at the same rate. (You could make the entire gate from plywood to eliminate any potential wood-movement problems.) The end caps overhang the faces of the panels V4" to allow easy grabbing. I attached each 4"-diameter section of PVC pipe to its panel from the inside with a couple of screws, then caulked around the perimeter. When you are assembling the top and bottom to the panels, first sandwich the slide between the panels, along with four pieces of paper. Removing the paper after assembly will create a small gap to allow easy sliding. I also waxed the slide to minimize friction. Jerry Darby Odessa, Texas Top and bottom -V x 2V4" x 6" PVC pipe (2) 4" dia.x 3V2" Caulk ring seals PVC pipe to panel a Closed o Open Front view A Cradle for Crosscutting Cylinders Crosscutting dowels, tubes or other cylindrical work can be dicey because round stock tends to spin out of control when the blade makes contact. For a safer approach, I mount the work in a shop-made cradle that consists of two beveled lengths of wood attached to a platform. To make the cradle, set your table-saw blade at 45° and rip the beveled pieces from the edges of a wide, thick board. Then glue or screw the pieces to the plywood platform, aligning their ends with one squared end of the panel. You can now clamp or screw the jig to your miter-saw table or table-saw crosscut sled. To use the jig, hold the round stock firmly in the cradle and make the cut slowly and steadily to prevent spinning. For extra friction, you can glue sandpaper to the bearing faces of the beveled pieces. Andy Roe Miter saw table Asheiille, North Carolina continued on page 26 Beveled pieces form a 90° angle Plywood platform 24 Popular Woodworking October 2003 |