Popular Woodworking 2003-11 № 137, страница 99

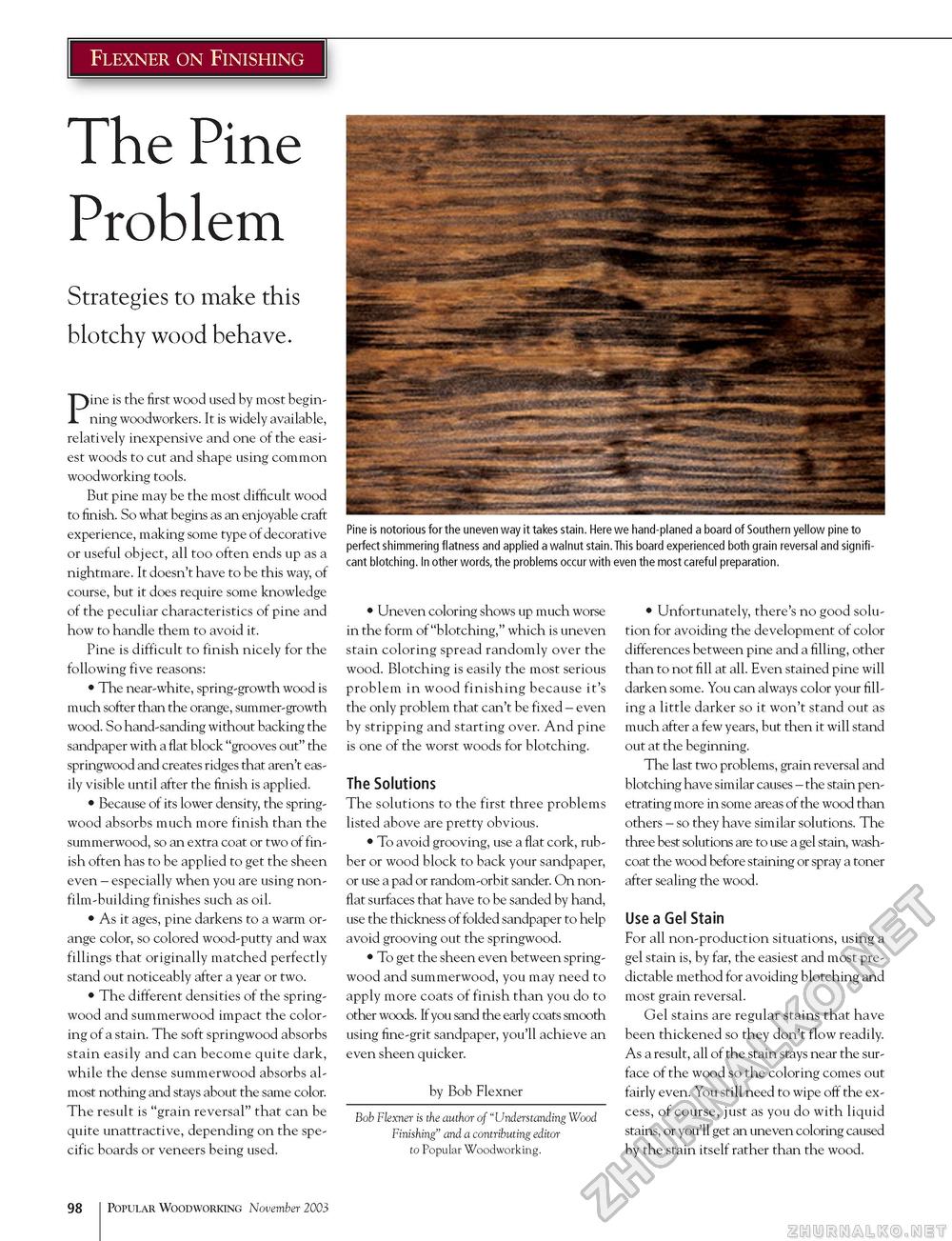

Flexner on Finishing The Pine Problem Strategies to make this blotchy wood behave. Pine is notorious for the uneven way it takes stain. Here we hand-planed a board of Southern yellow pine to perfect shimmering flatness and applied a walnut stain.This board experienced both grain reversal and significant blotching. In other words, the problems occur with even the most careful preparation. Pine is the first wood used by most beginning woodworkers. It is widely available, relatively inexpensive and one of the easiest woods to cut and shape using common woodworking tools. But pine may be the most difficult wood to finish. So what begins as an enjoyable craft experience, making some type of decorative or useful object, all too often ends up as a nightmare. It doesn't have to be this way, of course, but it does require some knowledge of the peculiar characteristics of pine and how to handle them to avoid it. Pine is difficult to finish nicely for the following five reasons: • The near-white, spring-growth wood is much softer than the orange, summer-growth wood. So hand-sanding without backing the sandpaper with a flat block "grooves out" the springwood and creates ridges that aren't easily visible until after the finish is applied. • Because of its lower density, the spring-wood absorbs much more finish than the summerwood, so an extra coat or two of finish often has to be applied to get the sheen even - especially when you are using non-film-building finishes such as oil. • As it ages, pine darkens to a warm orange color, so colored wood-putty and wax fillings that originally matched perfectly stand out noticeably after a year or two. • The different densities of the spring-wood and summerwood impact the coloring of a stain. The soft springwood absorbs stain easily and can become quite dark, while the dense summerwood absorbs almost nothing and stays about the same color. The result is "grain reversal" that can be quite unattractive, depending on the specific boards or veneers being used. • Uneven coloring shows up much worse in the form of "blotching," which is uneven stain coloring spread randomly over the wood. Blotching is easily the most serious problem in wood finishing because it's the only problem that can't be fixed - even by stripping and starting over. And pine is one of the worst woods for blotching. The Solutions The solutions to the first three problems listed above are pretty obvious. • To avoid grooving, use a flat cork, rubber or wood block to back your sandpaper, or use a pad or random-orbit sander. On non-flat surfaces that have to be sanded by hand, use the thickness of folded sandpaper to help avoid grooving out the springwood. • To get the sheen even between spring-wood and summerwood, you may need to apply more coats of finish than you do to other woods. If you sand the early coats smooth using fine-grit sandpaper, you'll achieve an even sheen quicker. by Bob Flexner Bob Flexner is the author of "Understanding Wood Finishing" and a contributing editor to Popular Woodworking. • Unfortunately, there's no good solution for avoiding the development of color differences between pine and a filling, other than to not fill at all. Even stained pine will darken some. You can always color your filling a little darker so it won't stand out as much after a few years, but then it will stand out at the beginning. The last two problems, grain reversal and blotching have similar causes - the stain penetrating more in some areas of the wood than others - so they have similar solutions. The three best solutions are to use a gel stain, wash-coat the wood before staining or spray a toner after sealing the wood. Use a Gel Stain For all non-production situations, using a gel stain is, by far, the easiest and most predictable method for avoiding blotching and most grain reversal. Gel stains are regular stains that have been thickened so they don't flow readily. As a result, all of the stain stays near the surface of the wood so the coloring comes out fairly even. You still need to wipe off the excess, of course, just as you do with liquid stains, or you'll get an uneven coloring caused by the stain itself rather than the wood. 98 Popular Woodworking November 2003 |