Popular Woodworking 2003-12 № 138, страница 99

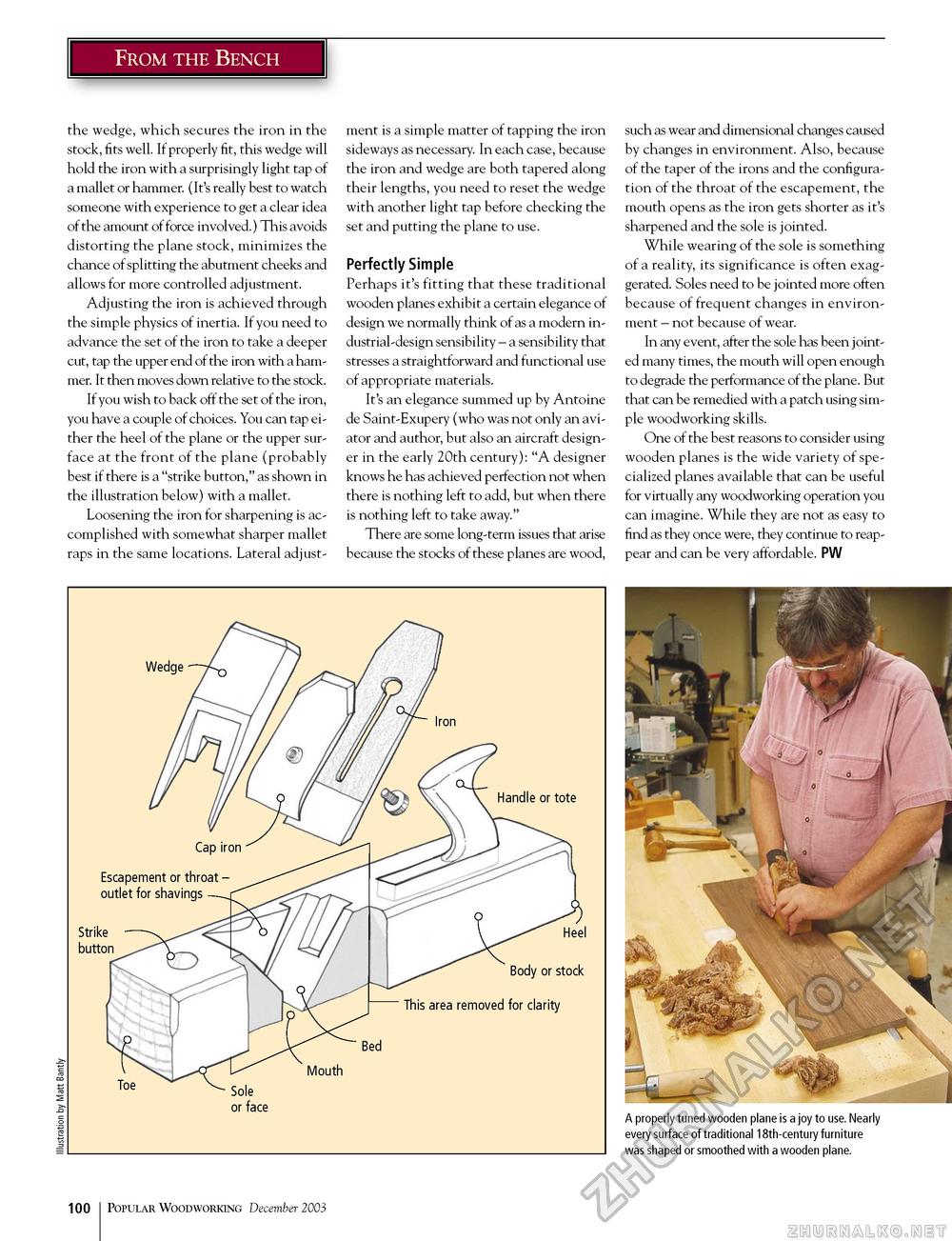

From the Bench the wedge, which secures the iron in the stock, fits well. If properly fit, this wedge will hold the iron with a surprisingly light tap of a mallet or hammer. (It's really best to watch someone with experience to get a clear idea of the amount of force involved.) This avoids distorting the plane stock, minimizes the chance of splitting the abutment cheeks and allows for more controlled adjustment. Adjusting the iron is achieved through the simple physics of inertia. If you need to advance the set of the iron to take a deeper cut, tap the upper end of the iron with a hammer. It then moves down relative to the stock. If you wish to back off the set of the iron, you have a couple of choices. You can tap either the heel of the plane or the upper surface at the front of the plane (probably best if there is a "strike button," as shown in the illustration below) with a mallet. Loosening the iron for sharpening is accomplished with somewhat sharper mallet raps in the same locations. Lateral adjust ment is a simple matter of tapping the iron sideways as necessary. In each case, because the iron and wedge are both tapered along their lengths, you need to reset the wedge with another light tap before checking the set and putting the plane to use. Perfectly Simple Perhaps it's fitting that these traditional wooden planes exhibit a certain elegance of design we normally think of as a modern industrial-design sensibility - a sensibility that stresses a straightforward and functional use of appropriate materials. It's an elegance summed up by Antoine de Saint-Exupery (who was not only an aviator and author, but also an aircraft designer in the early 20th century): "A designer knows he has achieved perfection not when there is nothing left to add, but when there is nothing left to take away." There are some long-term issues that arise because the stocks of these planes are wood, such as wear and dimensional changes caused by changes in environment. Also, because of the taper of the irons and the configuration of the throat of the escapement, the mouth opens as the iron gets shorter as it's sharpened and the sole is jointed. While wearing of the sole is something of a reality, its significance is often exaggerated. Soles need to be jointed more often because of frequent changes in environment - not because of wear. In any event, after the sole has been jointed many times, the mouth will open enough to degrade the performance of the plane. But that can be remedied with a patch using simple woodworking skills. One of the best reasons to consider using wooden planes is the wide variety of specialized planes available that can be useful for virtually any woodworking operation you can imagine. While they are not as easy to find as they once were, they continue to reappear and can be very affordable. PW A properly tuned wooden plane is a joy to use. Nearly every surface of traditional 18th-century furniture was shaped or smoothed with a wooden plane. 100 Popular Woodworking December 2003 |