Popular Woodworking 2004-04 № 140, страница 18

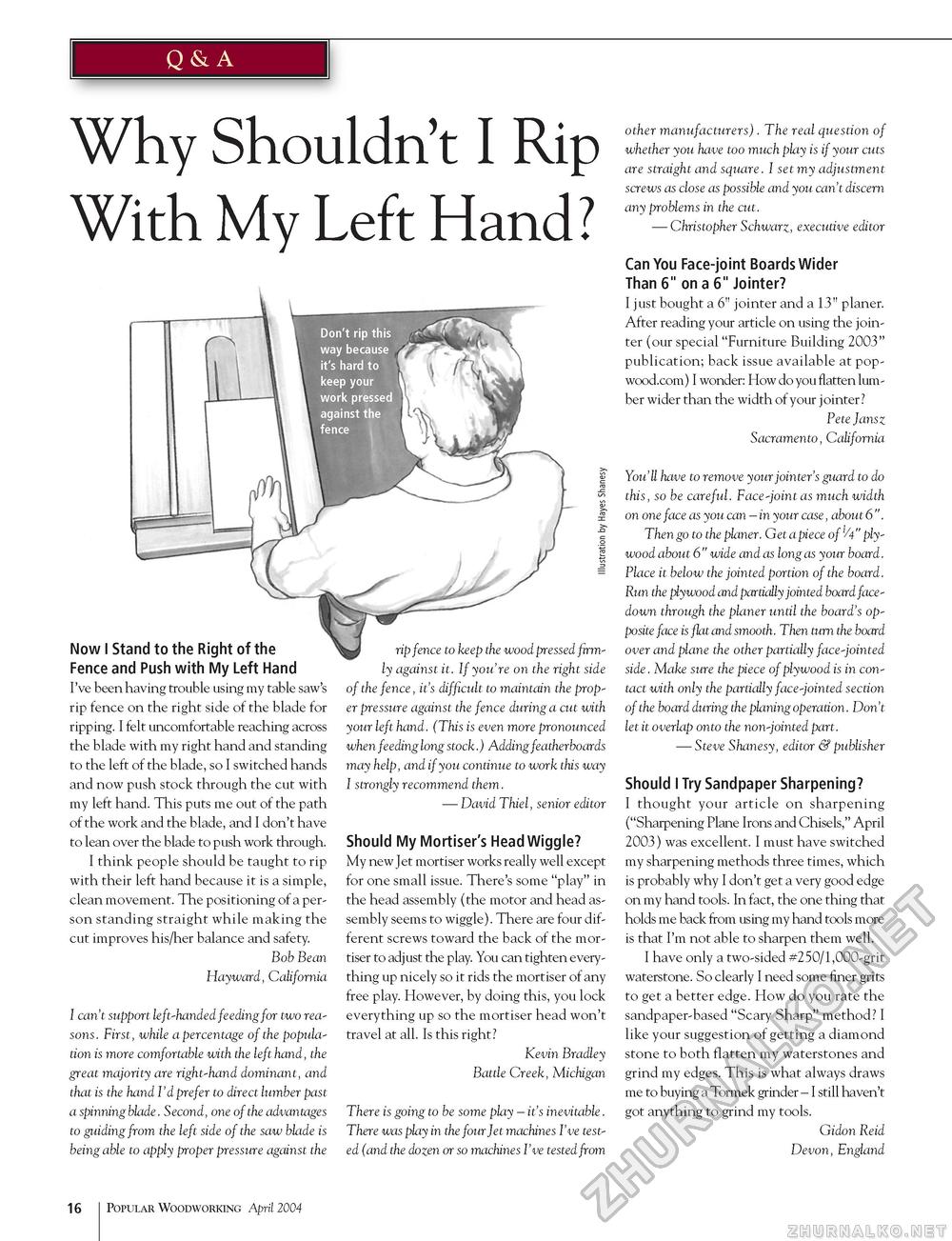

Q & A Why Shouldn't I Rip With My Left Hand? Now I Stand to the Right of the Fence and Push with My Left Hand I've been having trouble using my table saw's rip fence on the right side of the blade for ripping. I felt uncomfortable reaching across the blade with my right hand and standing to the left of the blade, so I switched hands and now push stock through the cut with my left hand. This puts me out of the path of the work and the blade, and I don't have to lean over the blade to push work through. I think people should be taught to rip with their left hand because it is a simple, clean movement. The positioning of a person standing straight while making the cut improves his/her balance and safety. Bob Bean Hayward, California I can't support left-handed feeding for two reasons. First, while a percentage of the population is more comfortable with the left hand, the great majority are right-hand dominant, and that is the hand I'd prefer to direct lumber past a spinning blade. Second, one of the advantages to guiding from the left side of the saw blade is being able to apply proper pressure against the rip fence to keep the wood pressed firmly against it. If you're on the right side of the fence, it's difficult to maintain the proper pressure against the fence during a cut with your left hand. (This is even more pronounced when feeding long stock.) Adding featherboards may help, and if you continue to work this way I strongly recommend them. — David Thiel, senior editor Should My Mortiser's Head Wiggle? My new Jet mortiser works really well except for one small issue. There's some "play" in the head assembly (the motor and head assembly seems to wiggle). There are four different screws toward the back of the mor-tiser to adjust the play. You can tighten everything up nicely so it rids the mortiser of any free play. However, by doing this, you lock everything up so the mortiser head won't travel at all. Is this right? Kevin Bradley Battle Creek, Michigan There is going to be some play - it's inevitable. There was play in the four Jet machines I've tested (and the dozen or so machines I've tested from other manufacturers). The real question of whether you have too much play is if your cuts are straight and square. I set my adjustment screws as close as possible and you can't discern any problems in the cut. — Christopher Schwarz, executive editor Can You Face-joint Boards Wider Than 6" on a 6" Jointer? I just bought a 6" jointer and a 13" planer. After reading your article on using the jointer (our special "Furniture Building 2003" publication; back issue available at pop-wood.com) I wonder: How do you flatten lumber wider than the width of your jointer? Pete Jansz Sacramento, California You'll have to remove your jointer's guard to do this, so be careful. Face-joint as much width on one face as you can - in your case, about 6". Then go to the planer. Get a piece of l/4 " plywood about 6" wide and as long as your board. Place it below the jointed portion of the board. Run the plywood and partially jointed board facedown through the planer until the board's opposite face is flat and smooth. Then turn the board over and plane the other partially face-jointed side. Make sure the piece of plywood is in contact with only the partially face-jointed section of the board during the planing operation. Don't let it overlap onto the non-jointed part. — Steve Shanesy, editor & publisher Should I Try Sandpaper Sharpening? I thought your article on sharpening ("Sharpening Plane Irons and Chisels," April 2003) was excellent. I must have switched my sharpening methods three times, which is probably why I don't get a very good edge on my hand tools. In fact, the one thing that holds me back from using my hand tools more is that I'm not able to sharpen them well. I have only a two-sided #250/1,000-grit waterstone. So clearly I need some finer grits to get a better edge. How do you rate the sandpaper-based "Scary Sharp" method? I like your suggestion of getting a diamond stone to both flatten my waterstones and grind my edges. This is what always draws me to buying a Tormek grinder - I still haven't got anything to grind my tools. Gidon Reid Devon, England 16 Popular Woodworking April 2004 |