Popular Woodworking 2004-04 № 140, страница 89

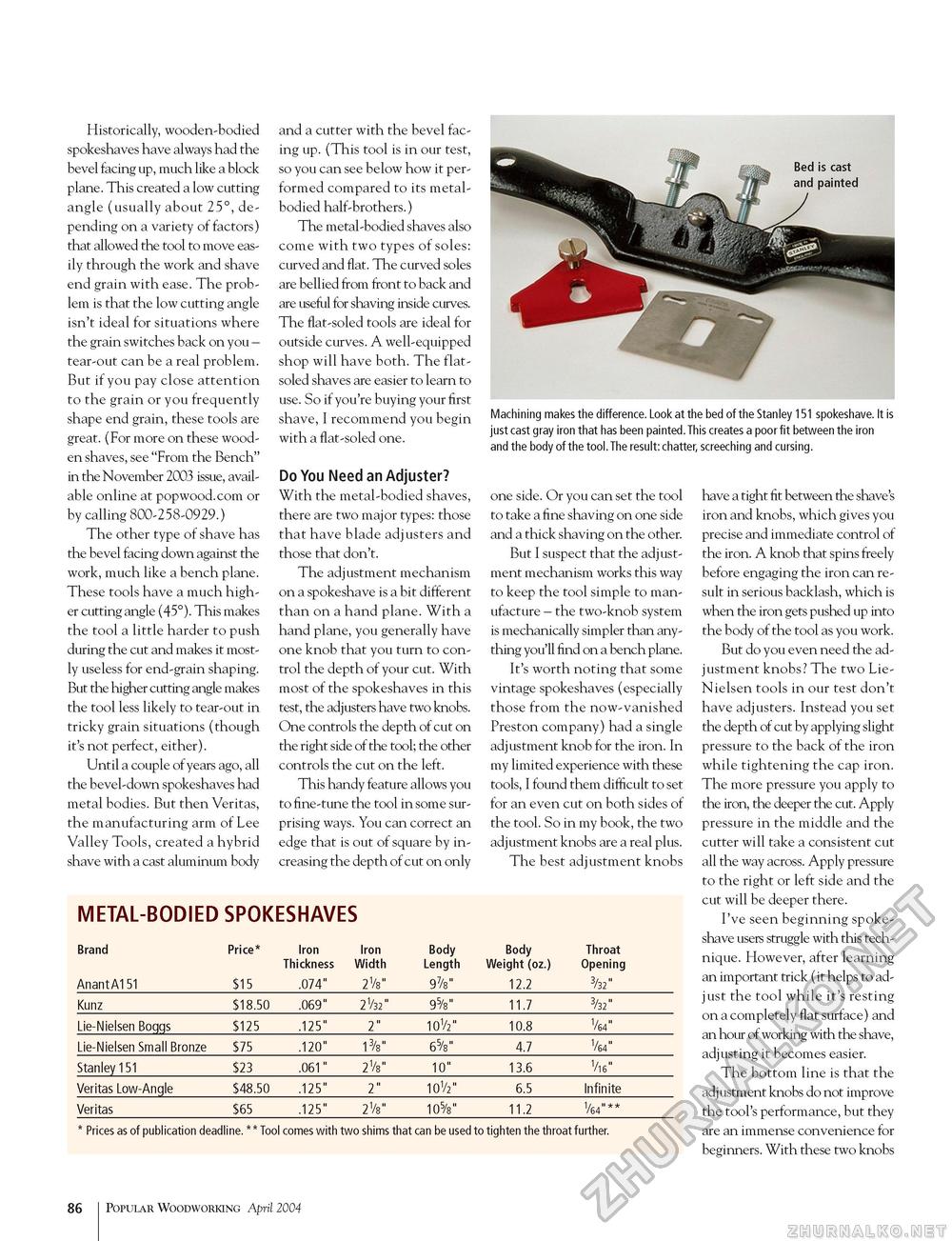

Machining makes the difference. Look at the bed of the Stanley 151 spokeshave. It is just cast gray iron that has been painted.This creates a poor fit between the iron and the body of the tool.The result: chatter, screeching and cursing. Historically, wooden-bodied spokeshaves have always had the bevel facing up, much like a block plane. This created a low cutting angle (usually about 25°, depending on a variety of factors) that allowed the tool to move easily through the work and shave end grain with ease. The problem is that the low cutting angle isn't ideal for situations where the grain switches back on you -tear-out can be a real problem. But if you pay close attention to the grain or you frequently shape end grain, these tools are great. (For more on these wooden shaves, see "From the Bench" in the November 2003 issue, available online at popwood.com or by calling 800-258-0929.) The other type of shave has the bevel facing down against the work, much like a bench plane. These tools have a much higher cutting angle (45°). This makes the tool a little harder to push during the cut and makes it mostly useless for end-grain shaping. But the higher cutting angle makes the tool less likely to tear-out in tricky grain situations (though it's not perfect, either). Until a couple of years ago, all the bevel-down spokeshaves had metal bodies. But then Veritas, the manufacturing arm of Lee Valley Tools, created a hybrid shave with a cast aluminum body and a cutter with the bevel facing up. (This tool is in our test, so you can see below how it performed compared to its metal-bodied half-brothers.) The metal-bodied shaves also come with two types of soles: curved and flat. The curved soles are bellied from front to back and are useful for shaving inside curves. The flat-soled tools are ideal for outside curves. A well-equipped shop will have both. The flat-soled shaves are easier to learn to use. So if you're buying your first shave, I recommend you begin with a flat-soled one. Do You Need an Adjuster? With the metal-bodied shaves, there are two major types: those that have blade adjusters and those that don't. The adjustment mechanism on a spokeshave is a bit different than on a hand plane. With a hand plane, you generally have one knob that you turn to control the depth of your cut. With most of the spokeshaves in this test, the adjusters have two knobs. One controls the depth of cut on the right side of the tool; the other controls the cut on the left. This handy feature allows you to fine-tune the tool in some surprising ways. You can correct an edge that is out of square by increasing the depth of cut on only one side. Or you can set the tool to take a fine shaving on one side and a thick shaving on the other. But I suspect that the adjustment mechanism works this way to keep the tool simple to manufacture - the two-knob system is mechanically simpler than anything you'll find on a bench plane. It's worth noting that some vintage spokeshaves (especially those from the now-vanished Preston company) had a single adjustment knob for the iron. In my limited experience with these tools, I found them difficult to set for an even cut on both sides of the tool. So in my book, the two adjustment knobs are a real plus. The best adjustment knobs have a tight fit between the shave's iron and knobs, which gives you precise and immediate control of the iron. A knob that spins freely before engaging the iron can result in serious backlash, which is when the iron gets pushed up into the body of the tool as you work. But do you even need the adjustment knobs? The two Lie-Nielsen tools in our test don't have adjusters. Instead you set the depth of cut by applying slight pressure to the back of the iron while tightening the cap iron. The more pressure you apply to the iron, the deeper the cut. Apply pressure in the middle and the cutter will take a consistent cut all the way across. Apply pressure to the right or left side and the cut will be deeper there. I've seen beginning spoke-shave users struggle with this technique. However, after learning an important trick (it helps to adjust the tool while it's resting on a completely flat surface) and an hour of working with the shave, adjusting it becomes easier. The bottom line is that the adjustment knobs do not improve the tool's performance, but they are an immense convenience for beginners. With these two knobs METAL-BODIED SPOKESHAVES

86 Popular Woodworking April 2004 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||