Popular Woodworking 2004-04 № 140, страница 97

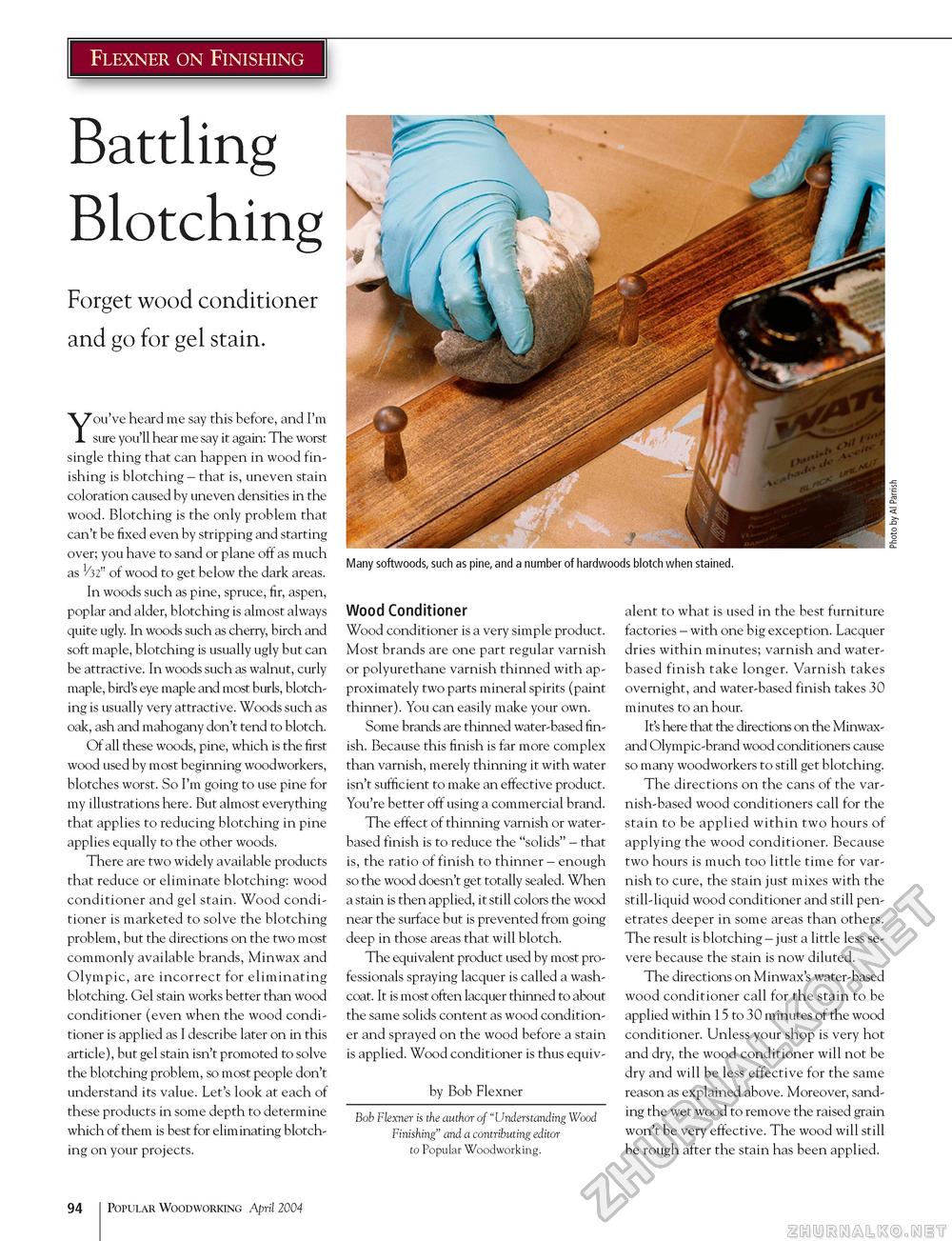

Flexner on Finishing Battling Blotching Forget wood conditioner and go for gel stain. Many softwoods, such as pine, and a number of hardwoods blotch when stained. You've heard me say this before, and I'm sure you'll hear me say it again: The worst single thing that can happen in wood finishing is blotching - that is, uneven stain coloration caused by uneven densities in the wood. Blotching is the only problem that can't be fixed even by stripping and starting over; you have to sand or plane off as much as 1/32" of wood to get below the dark areas. In woods such as pine, spruce, fir, aspen, poplar and alder, blotching is almost always quite ugly. In woods such as cherry, birch and soft maple, blotching is usually ugly but can be attractive. In woods such as walnut, curly maple, bird's eye maple and most burls, blotching is usually very attractive. Woods such as oak, ash and mahogany don't tend to blotch. Of all these woods, pine, which is the first wood used by most beginning woodworkers, blotches worst. So I'm going to use pine for my illustrations here. But almost everything that applies to reducing blotching in pine applies equally to the other woods. There are two widely available products that reduce or eliminate blotching: wood conditioner and gel stain. Wood conditioner is marketed to solve the blotching problem, but the directions on the two most commonly available brands, Minwax and Olympic, are incorrect for eliminating blotching. Gel stain works better than wood conditioner (even when the wood conditioner is applied as I describe later on in this article), but gel stain isn't promoted to solve the blotching problem, so most people don't understand its value. Let's look at each of these products in some depth to determine which of them is best for eliminating blotching on your projects. Wood Conditioner Wood conditioner is a very simple product. Most brands are one part regular varnish or polyurethane varnish thinned with approximately two parts mineral spirits (paint thinner). You can easily make your own. Some brands are thinned water-based finish. Because this finish is far more complex than varnish, merely thinning it with water isn't sufficient to make an effective product. You're better off using a commercial brand. The effect of thinning varnish or water-based finish is to reduce the "solids" - that is, the ratio of finish to thinner - enough so the wood doesn't get totally sealed. When a stain is then applied, it still colors the wood near the surface but is prevented from going deep in those areas that will blotch. The equivalent product used by most professionals spraying lacquer is called a wash-coat. It is most often lacquer thinned to about the same solids content as wood conditioner and sprayed on the wood before a stain is applied. Wood conditioner is thus equiv- by Bob Flexner Bob Flexner is the author of "Understanding Wood Finishing" and a contributing editor to Popular Woodworking. alent to what is used in the best furniture factories - with one big exception. Lacquer dries within minutes; varnish and water-based finish take longer. Varnish takes overnight, and water-based finish takes 30 minutes to an hour. It's here that the directions on the Minwax-and Olympic-brand wood conditioners cause so many woodworkers to still get blotching. The directions on the cans of the varnish-based wood conditioners call for the stain to be applied within two hours of applying the wood conditioner. Because two hours is much too little time for varnish to cure, the stain just mixes with the still-liquid wood conditioner and still penetrates deeper in some areas than others. The result is blotching - just a little less severe because the stain is now diluted. The directions on Minwax's water-based wood conditioner call for the stain to be applied within 15 to 30 minutes of the wood conditioner. Unless your shop is very hot and dry, the wood conditioner will not be dry and will be less effective for the same reason as explained above. Moreover, sanding the wet wood to remove the raised grain won't be very effective. The wood will still be rough after the stain has been applied. 94 Popular Woodworking April 2004 |