Popular Woodworking 2004-08 № 142, страница 12

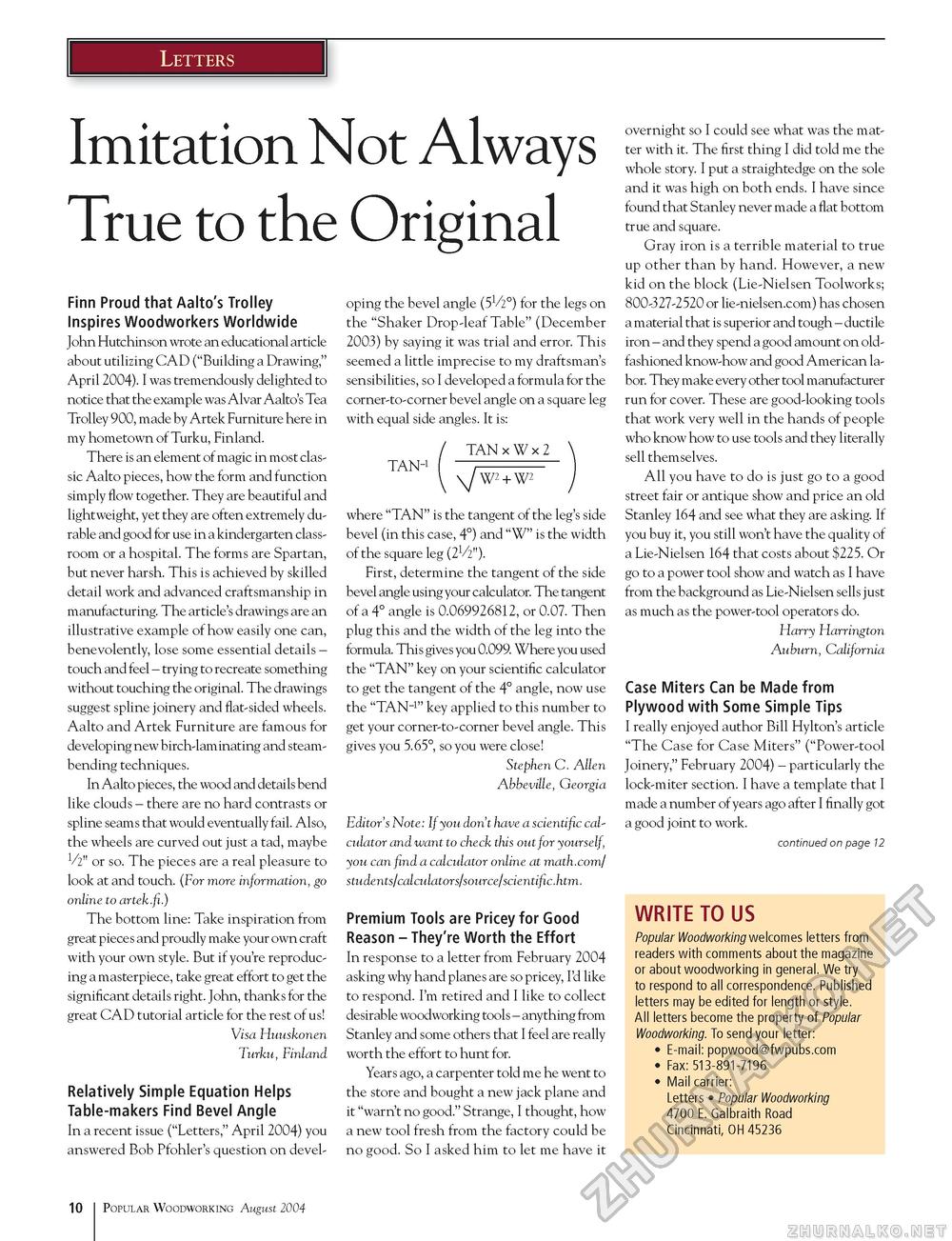

Letters Imitation Not Always True to the Original Finn Proud that Aalto's Trolley Inspires Woodworkers Worldwide John Hutchinson wrote an educational article about utilizing CAD ("Building a Drawing," April 2004). I was tremendously delighted to notice that the example was Alvar Aalto's Tea Trolley 900, made by Artek Furniture here in my hometown of Turku, Finland. There is an element of magic in most classic Aalto pieces, how the form and function simply flow together. They are beautiful and lightweight, yet they are often extremely durable and good for use in a kindergarten classroom or a hospital. The forms are Spartan, but never harsh. This is achieved by skilled detail work and advanced craftsmanship in manufacturing. The article's drawings are an illustrative example of how easily one can, benevolently, lose some essential details -touch and feel - trying to recreate something without touching the original. The drawings suggest spline joinery and flat-sided wheels. Aalto and Artek Furniture are famous for developing new birch-laminating and steam-bending techniques. In Aalto pieces, the wood and details bend like clouds - there are no hard contrasts or spline seams that would eventually fail. Also, the wheels are curved out just a tad, maybe V2" or so. The pieces are a real pleasure to look at and touch. (For more information, go online to artek.fi.) The bottom line: Take inspiration from great pieces and proudly make your own craft with your own style. But if you're reproducing a masterpiece, take great effort to get the significant details right. John, thanks for the great CAD tutorial article for the rest of us! Visa Huuskonen Turku, Finland Relatively Simple Equation Helps Table-makers Find Bevel Angle In a recent issue ("Letters," April 2004) you answered Bob Pfohler's question on devel oping the bevel angle (5V2°) for the legs on the "Shaker Drop-leaf Table" (December 2003) by saying it was trial and error. This seemed a little imprecise to my draftsman's sensibilities, so I developed a formula for the corner-to-corner bevel angle on a square leg with equal side angles. It is: / TAN x W x 2 \ TAN"1 y - y \yw2+w2 J where "TAN" is the tangent of the leg's side bevel (in this case, 4°) and "W" is the width of the square leg (2^//2"). First, determine the tangent of the side bevel angle using your calculator. The tangent of a 4° angle is 0.069926812, or 0.07. Then plug this and the width of the leg into the formula. This gives you 0.099. Where you used the "TAN" key on your scientific calculator to get the tangent of the 4° angle, now use the "TAN"1" key applied to this number to get your corner-to-corner bevel angle. This gives you 5.65°, so you were close! Stephen C. Allen Abbeville, Georgia Editor's Note: If you don't have a scientific calculator and want to check this out for yourself, you can find a calculator online at math.com/ students/calculators/source/scientific.htm. Premium Tools are Pricey for Good Reason - They're Worth the Effort In response to a letter from February 2004 asking why hand planes are so pricey, I'd like to respond. I'm retired and I like to collect desirable woodworking tools - anything from Stanley and some others that I feel are really worth the effort to hunt for. Years ago, a carpenter told me he went to the store and bought a new jack plane and it "warn't no good." Strange, I thought, how a new tool fresh from the factory could be no good. So I asked him to let me have it overnight so I could see what was the matter with it. The first thing I did told me the whole story. I put a straightedge on the sole and it was high on both ends. I have since found that Stanley never made a flat bottom true and square. Gray iron is a terrible material to true up other than by hand. However, a new kid on the block (Lie-Nielsen Toolworks; 800-327-2520 or lie-nielsen.com) has chosen a material that is superior and tough - ductile iron - and they spend a good amount on old-fashioned know-how and good American labor. They make every other tool manufacturer run for cover. These are good-looking tools that work very well in the hands of people who know how to use tools and they literally sell themselves. All you have to do is just go to a good street fair or antique show and price an old Stanley 164 and see what they are asking. If you buy it, you still won't have the quality of a Lie-Nielsen 164 that costs about $225. Or go to a power tool show and watch as I have from the background as Lie-Nielsen sells just as much as the power-tool operators do. Harry Harrington Auburn, California Case Miters Can be Made from Plywood with Some Simple Tips I really enjoyed author Bill Hylton's article "The Case for Case Miters" ("Power-tool Joinery," February 2004) - particularly the lock-miter section. I have a template that I made a number of years ago after I finally got a good joint to work. continued on page 12 WRITE TO US Popular Woodworking welcomes letters from readers with comments about the magazine or about woodworking in general. We try to respond to all correspondence. Published letters may be edited for length or style. All letters become the property of Popular Woodworking. To send your letter: • E-mail: popwood@fwpubs.com • Fax: 513-891-7196 • Mail carrier: Letters • Popular Woodworking 4700 E. Galbraith Road Cincinnati, OH 45236 10 Popular Woodworking August 2004 |