Popular Woodworking 2004-11 № 144, страница 30

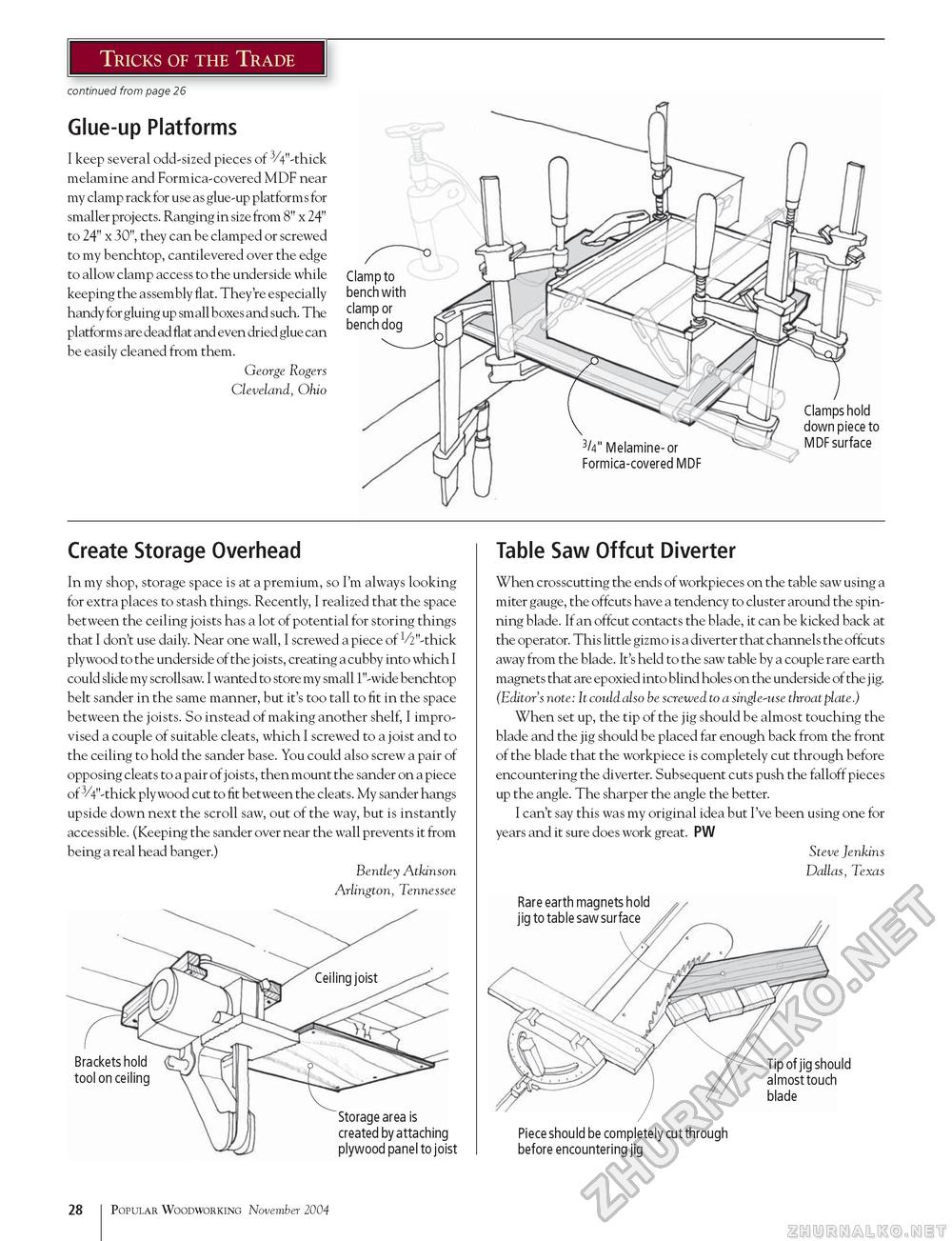

Tricks of the Trade continued from page 26 Glue-up Platforms I keep several odd-sized pieces of 3/4"-thick melamine and Formica-covered MDF near my clamp rack for use as glue-up platforms for smaller projects. Ranging in size from 8" x 24" to 24" x 30", they can be clamped or screwed to my benchtop, cantilevered over the edge to allow clamp access to the underside while keeping the assembly flat. They're especially handy for gluing up small boxes and such. The platforms are dead flat and even dried glue can be easily cleaned from them. George Rogers Cleveland, Ohio Clamp to bench with clamp or bench dog Clamps hold down piece to MDF surface Create Storage Overhead In my shop, storage space is at a premium, so I'm always looking for extra places to stash things. Recently, I realized that the space between the ceiling joists has a lot of potential for storing things that I don't use daily. Near one wall, I screwed a piece of V2"-thick plywood to the underside of the joists, creating a cubby into which I could slide my scrollsaw. I wanted to store my small l"-wide benchtop belt sander in the same manner, but it's too tall to fit in the space between the joists. So instead of making another shelf, I improvised a couple of suitable cleats, which I screwed to a joist and to the ceiling to hold the sander base. You could also screw a pair of opposing cleats to a pair of joists, then mount the sander on a piece of 3/4"-thick plywood cut to fit between the cleats. My sander hangs upside down next the scroll saw, out of the way, but is instantly accessible. (Keeping the sander over near the wall prevents it from being a real head banger.) Bentley Atkinson Arlington, Tennessee Table Saw Offcut Diverter When crosscutting the ends of workpieces on the table saw using a miter gauge, the offcuts have a tendency to cluster around the spinning blade. If an offcut contacts the blade, it can be kicked back at the operator. This little gizmo is a diverter that channels the offcuts away from the blade. It's held to the saw table by a couple rare earth magnets that are epoxied into blind holes on the underside of the j ig. (Editor's note: It could also be screwed to a single-use throat plate.) When set up, the tip of the jig should be almost touching the blade and the jig should be placed far enough back from the front of the blade that the workpiece is completely cut through before encountering the diverter. Subsequent cuts push the falloff pieces up the angle. The sharper the angle the better. I can't say this was my original idea but I've been using one for years and it sure does work great. PW Steve Jenkins Dallas, Texas Piece should be completely cut through before encountering jig 28 Popular Woodworking November 2004 |