Popular Woodworking 2005-04 № 147, страница 14

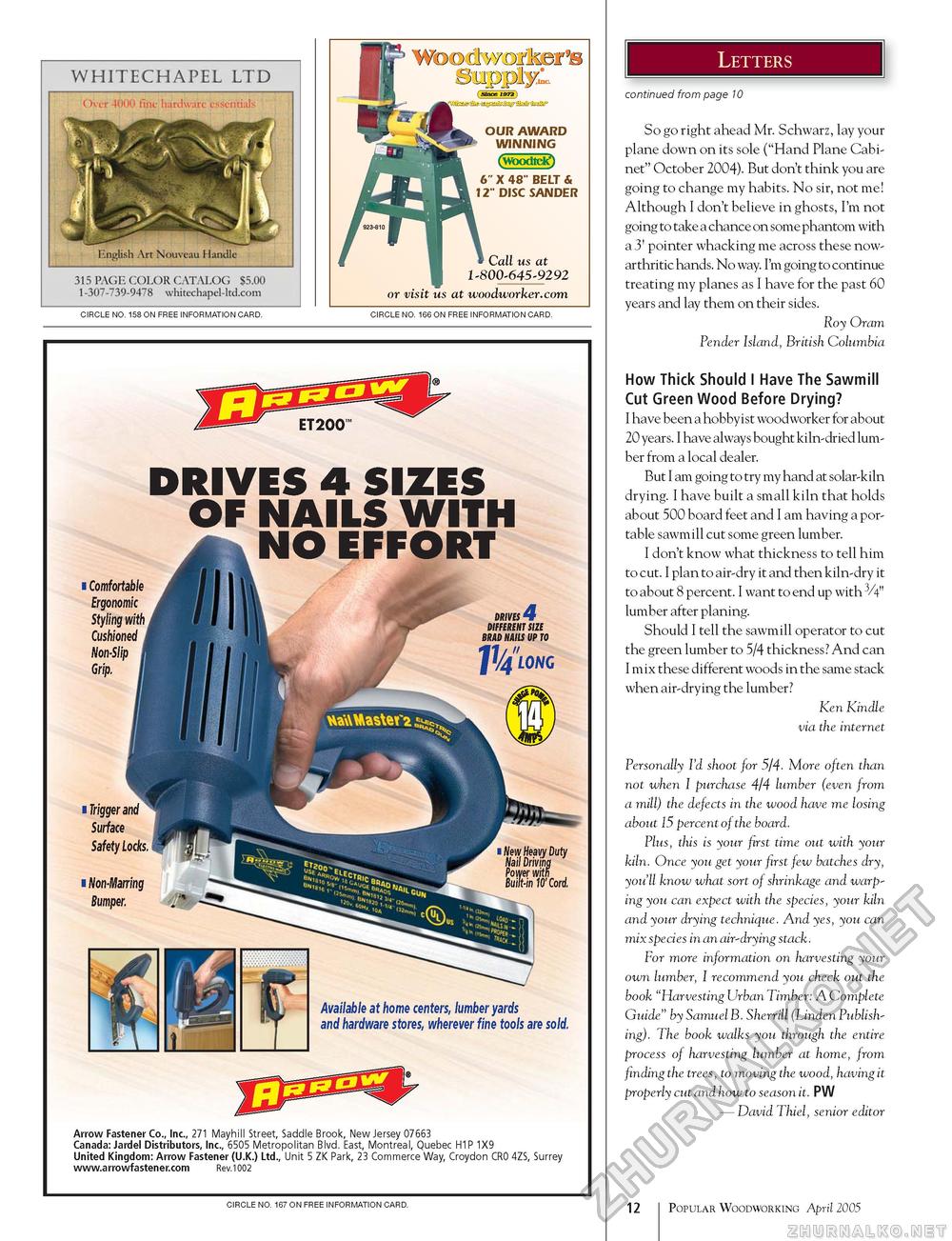

CIRCLE NO. 158 ON FREE INFORMATION CARD. CIRCLE NO. 166 ON FREE INFORMATION CARD. ET200™ DRIVES 4 OF NAILS WITH NO EFFORT Comfortable Ergonomic Styling with Cushioned Non-Slip Grip. drives 4 diffcrcnt size brad nails up to 1V4LONG Trigger and Surface Safety Locks. 1 Non-Marring Bumper. -J*

Available at home centers, lumber yards and hardware stores, wherever fine tools are sold. Arrow Fastener Co., Inc., 271 Mayhill Street, Saddle Brook, New Jersey 07663 Canada: Jardel Distributors, Inc., 6505 Metropolitan Blvd. East, Montreal, Quebec H1P 1X9 United Kingdom: Arrow Fastener (U.K.) Ltd., Unit 5 ZK Park, 23 Commerce Way, Croydon CR0 4ZS, Surrey www.arrowfastener.com Rev. 1002 Letters continued from page 10 So go right ahead Mr. Schwarz, lay your plane down on its sole ("Hand Plane Cabinet" October 2004). But don't think you are going to change my habits. No sir, not me! Although I don't believe in ghosts, I'm not going to take a chance on some phantom with a 3' pointer whacking me across these now-arthritic hands. No way. I'm going to continue treating my planes as I have for the past 60 years and lay them on their sides. Roy Oram Pender Island, British Columbia How Thick Should I Have The Sawmill Cut Green Wood Before Drying? I have been a hobbyist woodworker for about 20 years. I have always bought kiln-dried lumber from a local dealer. But I am going to try my hand at solar-kiln drying. I have built a small kiln that holds about 500 board feet and I am having a portable sawmill cut some green lumber. I don't know what thickness to tell him to cut. I plan to air-dry it and then kiln-dry it to about 8 percent. I want to end up with 3/4" lumber after planing. Should I tell the sawmill operator to cut the green lumber to 5/4 thickness? And can I mix these different woods in the same stack when air-drying the lumber? Ken Kindle via the internet Personally I'd shoot for 5/4. More often than not when I purchase 4/4 lumber (even from a mill) the defects in the wood have me losing about 15 percent of the board. Plus, this is your first time out with your kiln. Once you get your first few batches dry, you'll know what sort of shrinkage and warping you can expect with the species, your kiln and your drying technique. And yes, you can mix species in an air-drying stack. For more information on harvesting your own lumber, I recommend you check out the book "Harvesting Urban Timber: A Complete Guide" by Samuel B. Sherrill (Linden Publishing). The book walks you through the entire process of harvesting lumber at home, from finding the trees, to moving the wood, having it properly cut and how to season it. PW — David Thiel, senior editor CIRCLE NO. 167 ON FREE INFORMATION CARD. 12 Popular Woodworking April 2005 |