Popular Woodworking 2005-04 № 147, страница 24

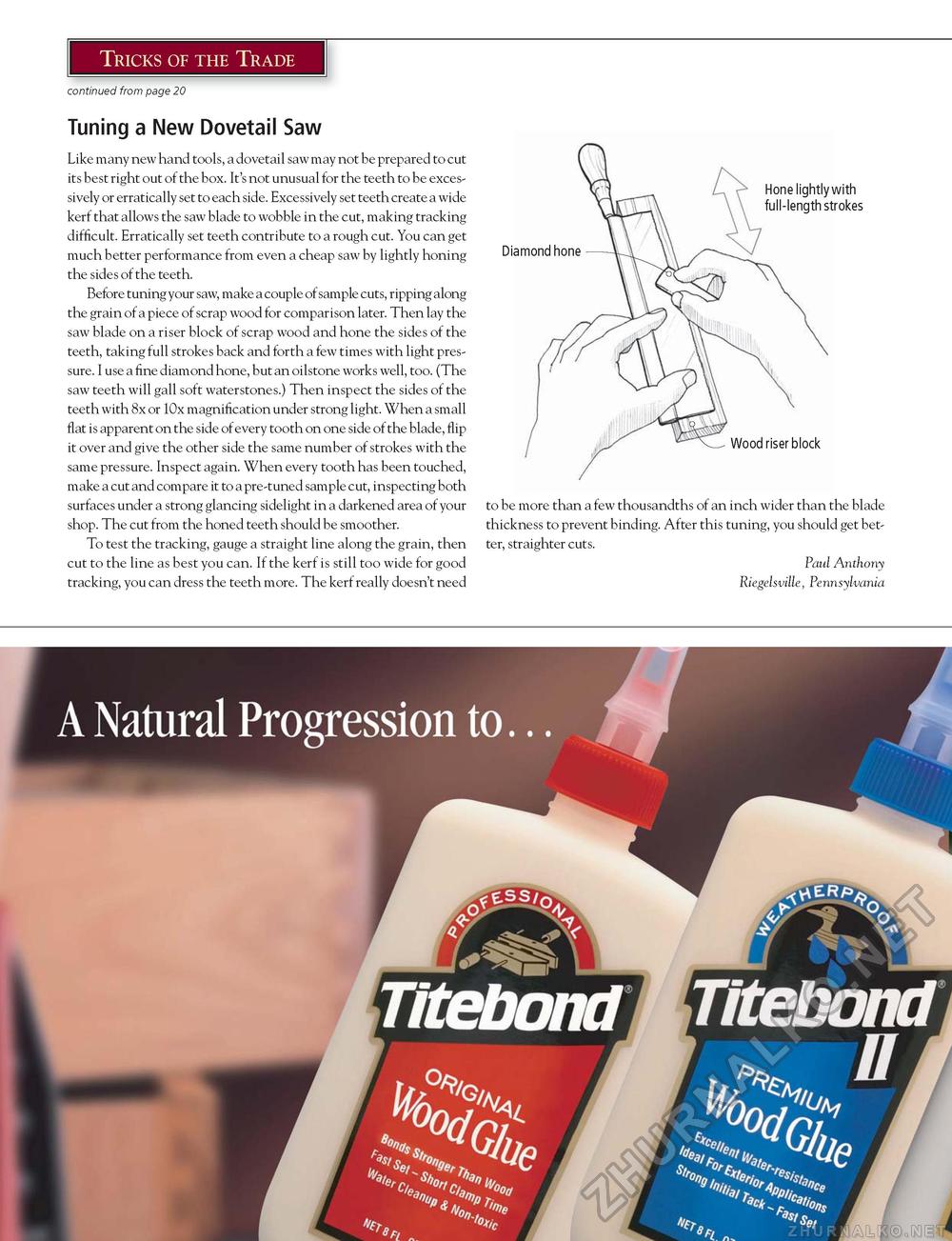

Tricks of the Trade continued from page 20 Tuning a New Dovetail Saw Like many new hand tools, a dovetail saw may not be prepared to cut its best right out of the box. It's not unusual for the teeth to be excessively or erratically set to each side. Excessively set teeth create a wide kerf that allows the saw blade to wobble in the cut, making tracking difficult. Erratically set teeth contribute to a rough cut. You can get much better performance from even a cheap saw by lightly honing the sides of the teeth. Before tuning your saw, make a couple of sample cuts, ripping along the grain of a piece of scrap wood for comparison later. Then lay the saw blade on a riser block of scrap wood and hone the sides of the teeth, taking full strokes back and forth a few times with light pressure. I use a fine diamond hone, but an oilstone works well, too. (The saw teeth will gall soft waterstones.) Then inspect the sides of the teeth with 8x or 10x magnification under strong light. When a small flat is apparent on the side of every tooth on one side of the blade, flip it over and give the other side the same number of strokes with the same pressure. Inspect again. When every tooth has been touched, make a cut and compare it to a pre-tuned sample cut, inspecting both surfaces under a strong glancing sidelight in a darkened area of your shop. The cut from the honed teeth should be smoother. To test the tracking, gauge a straight line along the grain, then cut to the line as best you can. If the kerf is still too wide for good tracking, you can dress the teeth more. The kerf really doesn't need Hone lightly with full-length strokes Diamond hone Wood riser block to be more than a few thousandths of an inch wider than the blade thickness to prevent binding. After this tuning, you should get better, straighter cuts. Paul Anthony Riegelsville, Pennsylvania |