Popular Woodworking 2005-08 № 149, страница 86

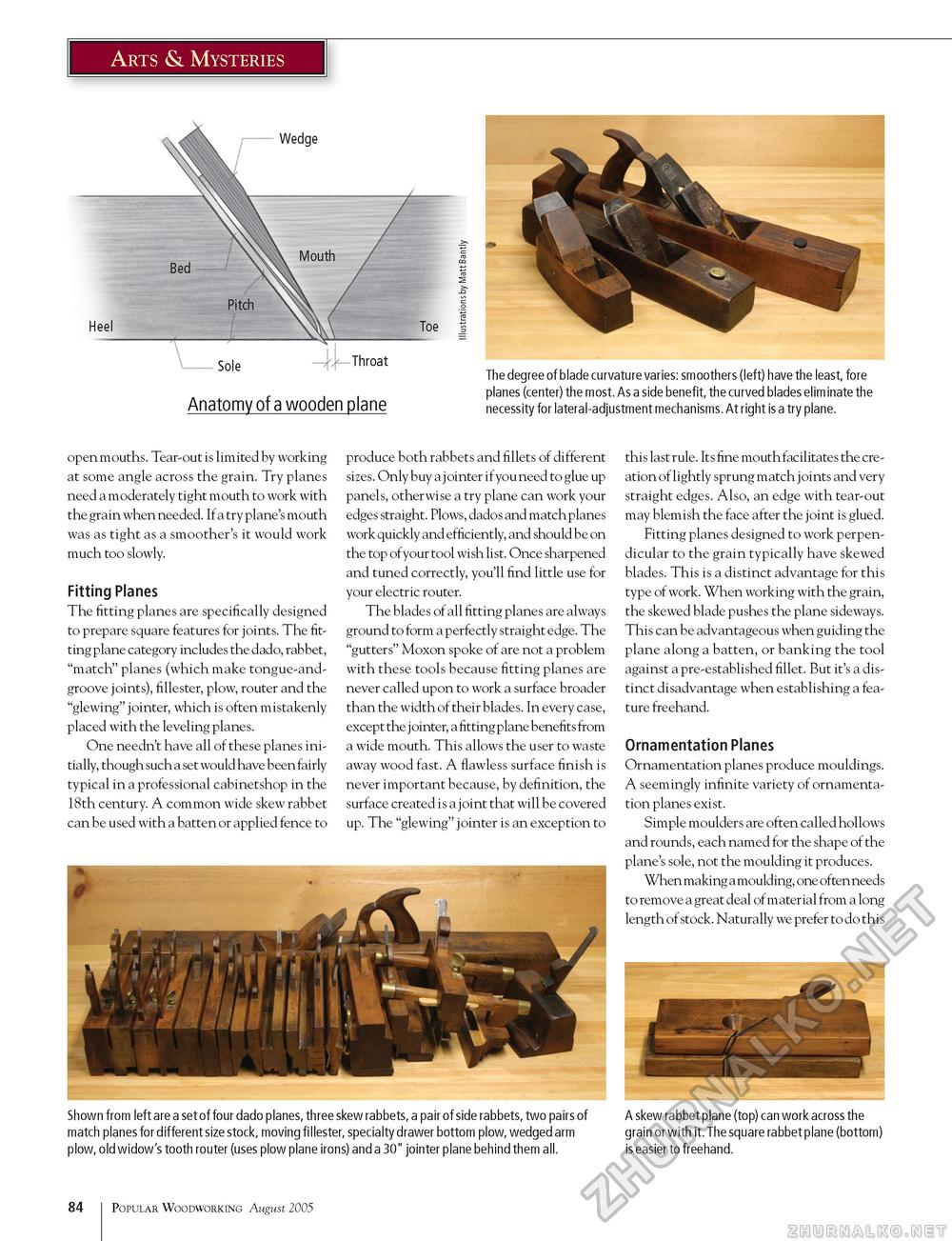

Arts & Mysteries ;-Sole Throat Anatomy of a wooden plane The degree of blade curvature varies: smoothers (left) have the least, fore planes (center) the most. As a side benefit, the curved blades elim inate the necessity for lateral-adjustment mechanisms. At right is a try plane. open mouths. Tear-out is limited by working at some angle across the grain. Try planes need a moderately tight mouth to work with the grain when needed. If a try plane's mouth was as tight as a smoother's it would work much too slowly. Fitting Planes The fitting planes are specifically designed to prepare square features for joints. The fitting plane category includes the dado, rabbet, "match" planes (which make tongue-and-groove joints), fillester, plow, router and the "glewing" jointer, which is often mistakenly placed with the leveling planes. One needn't have all of these planes initially, though such a set would have been fairly typical in a professional cabinetshop in the 18th century. A common wide skew rabbet can be used with a batten or applied fence to produce both rabbets and fillets of different sizes. Only buy a jointer if you need to glue up panels, otherwise a try plane can work your edges straight. Plows, dados and match planes work quickly and efficiently, and should be on the top ofyour tool wish list. Once sharpened and tuned correctly, you'll find little use for your electric router. The blades of all fitting planes are always ground to form a perfectly straight edge. The "gutters" Moxon spoke of are not a problem with these tools because fitting planes are never called upon to work a surface broader than the width of their blades. In every case, except the j ointer, a fitting plane benefits from a wide mouth. This allows the user to waste away wood fast. A flawless surface finish is never important because, by definition, the surface created is a joint that will be covered up. The "glewing" jointer is an exception to Shown from left are a set of four dado planes, three skew rabbets, a pair of side rabbets, two pairs of match planes for different size stock, moving fillester, specialty drawer bottom plow, wedged arm plow, old widow's tooth router (uses plow plane irons) and a 30" jointer plane behind them all. this last rule. Its fine mouth facilitates the creation of lightly sprung match joints and very straight edges. Also, an edge with tear-out may blemish the face after the joint is glued. Fitting planes designed to work perpendicular to the grain typically have skewed blades. This is a distinct advantage for this type of work. When working with the grain, the skewed blade pushes the plane sideways. This can be advantageous when guiding the plane along a batten, or banking the tool against a pre-established fillet. But it's a distinct disadvantage when establishing a feature freehand. Ornamentation Planes Ornamentation planes produce mouldings. A seemingly infinite variety of ornamentation planes exist. Simple moulders are often called hollows and rounds, each named for the shape of the plane's sole, not the moulding it produces. When making a moulding, one often needs to remove a great deal of material from a long length of stock. Naturally we prefer to do this A skew rabbet plane (top) can work across the grain or with it. The square rabbet plane (bottom) is easier to freehand. 84 Popular Woodworking August 2005 |