Popular Woodworking 2005-10 № 150, страница 22

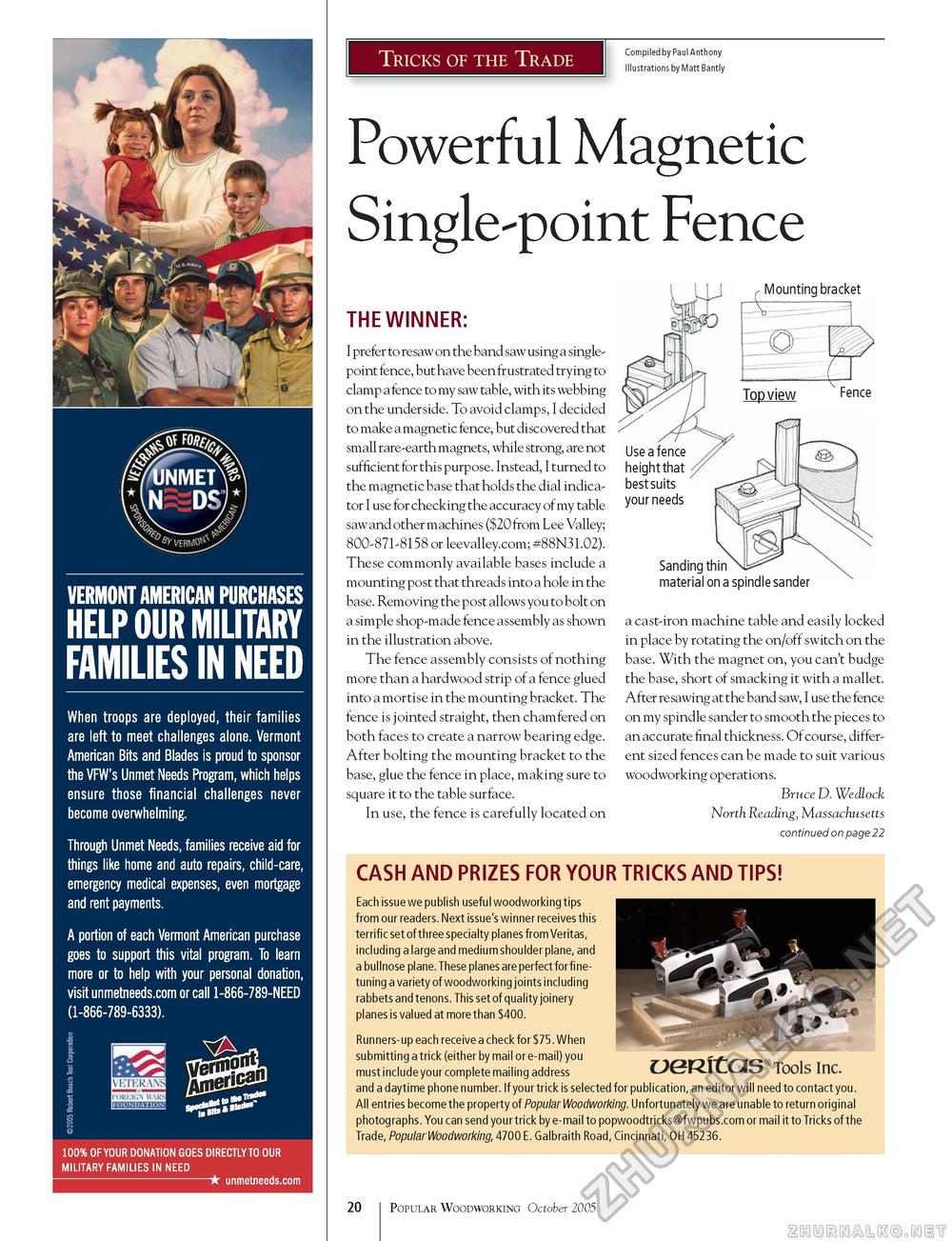

WNMETW VN DSJi i^vtm^jy VERMONT AMERICAN PURCHASES HELP OUR MILITARY FAMILIES IN NEED When troops are deployed, their families are left to meet challenges alone. Vermont American Bits and Blades is proud to sponsor the VFW's Unmet Needs Program, which helps ensure those financial challenges never become overwhelming. Through Unmet Needs, families receive aid for things like home and auto repairs, child-care, emergency medical expenses, even mortgage and rent payments. A portion of each Vermont American purchase goes to support this vital program. To learn more or to help with your personal donation, visit unmetneeds.com or call 1-866-789-NEED (1-866-789-6333). Tricks of the Trade Compiled by Paul Anthony Illustrations by Matt Bantly Powerful Magnetic Single-point Fence THE WINNER: I prefer to resaw on the band saw using a single-point fence, but have been frustrated trying to clamp afence to my saw table, with its webbing on the underside. To avoid clamps, I decided to make a magnetic fence, but discovered that small rare-earth magnets, while strong, are not sufficient for this purpose. Instead, I turned to the magnetic base that holds the dial indicator I use for checking the accuracy of my table saw and other machines ($20 from Lee Valley; 800-871-8158 or leevalley.com; #88N31.02). These commonly available bases include a mounting post that threads into a hole in the base. Removing the post allows you to bolt on a simple shop-made fence assembly as shown in the illustration above. The fence assembly consists of nothing more than a hardwood strip of a fence glued into a mortise in the mounting bracket. The fence is jointed straight, then chamfered on both faces to create a narrow bearing edge. After bolting the mounting bracket to the base, glue the fence in place, making sure to square it to the table surface. In use, the fence is carefully located on Mounting bracket Top view Fence OS Use a fence height that best suits your needs Sanding thin material on a spindle sander a cast-iron machine table and easily locked in place by rotating the on/off switch on the base. With the magnet on, you can't budge the base, short of smacking it with a mallet. After re sawing at the band saw, I use the fence on my spindle sander to smooth the pieces to an accurate final thickness. Of course, different sized fences can be made to suit various woodworking operations. Bruce D. Wedlock North Reading, Massachusetts continued on page 22 CASH AND PRIZES FOR YOUR TRICKS AND TIPS! Each issue we publish useful woodworking tips from our readers. Next issue's winner receives this terrific set of three specialty planes from Veritas, including a large and medium shoulder plane, and a bullnose plane. These planes are perfect for fine-tuning a variety of woodworking joints including rabbets and tenons. This set of quality joinery planes is valued at more than $400. Runners-up each receive a check for $75. When submitting a trick (either by mail or e-mail) you must include your complete mailing address and a daytime phone number. If your trick is selected for publication, an editor will need to contact you. All entries become the property of Popular Woodworking. Unfortunately we are unable to return original photographs. You can send your trick by e-mail to popwoodtricks@fwpubs.com or mail it to Tricks of the Trade, PopularWoodwoking, 4700 E. Galbraith Road, Cincinnati, OH 45236. OeRltQS Tools Inc. 20 Popular Woodworking October 2005 |