Popular Woodworking 2006-02 № 153, страница 37

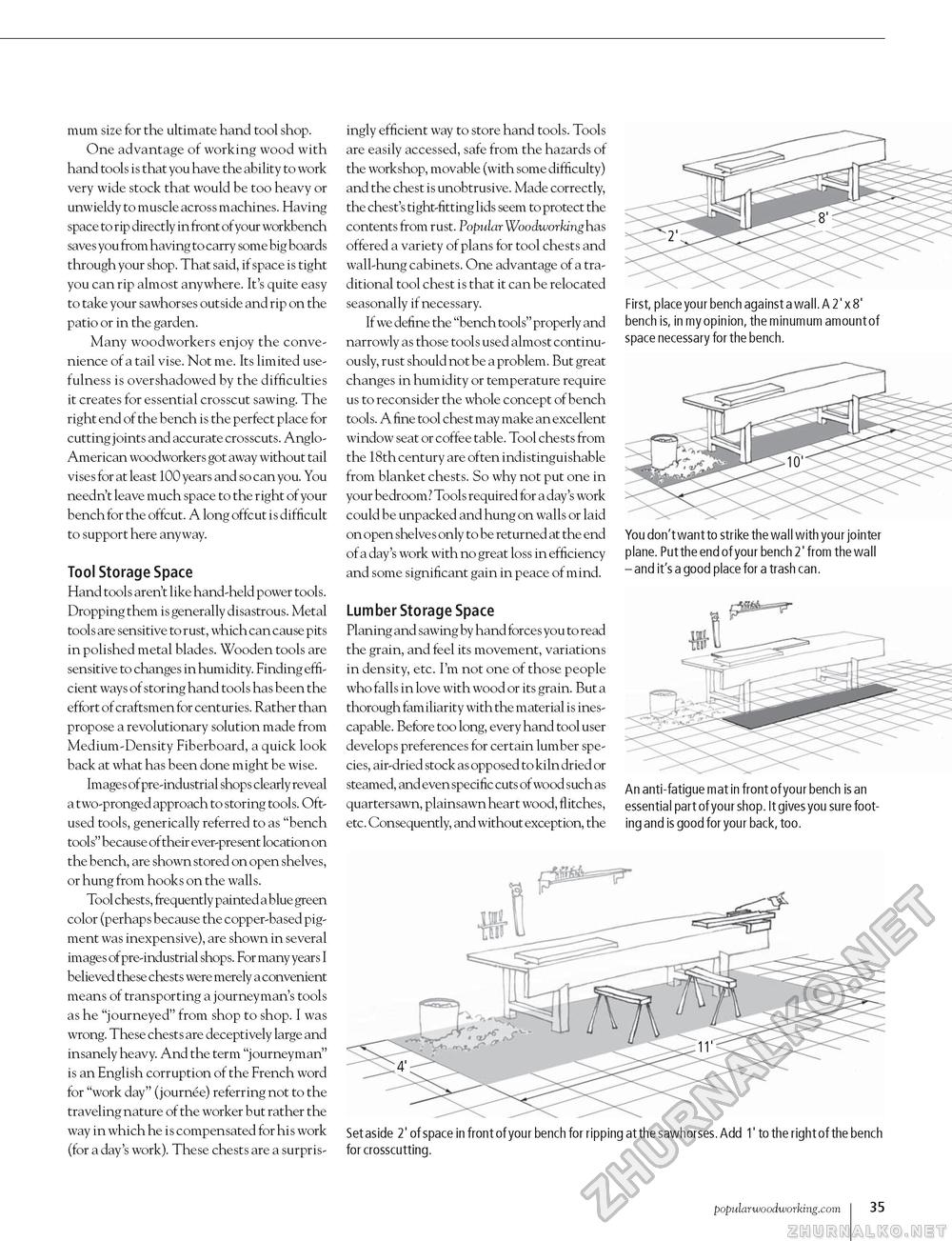

mum size for the ultimate hand tool shop. One advantage of working wood with hand tools is that you have the ability to work very wide stock that would be too heavy or unwieldy to muscle across machines. Having space to rip directly in front of your workbench saves you from having to carry some big boards through your shop. That said, if space is tight you can rip almost anywhere. It's quite easy to take your sawhorses outside and rip on the patio or in the garden. Many woodworkers enjoy the convenience of a tail vise. Not me. Its limited usefulness is overshadowed by the difficulties it creates for essential crosscut sawing. The right end of the bench is the perfect place for cutting joints and accurate crosscuts. Anglo-American woodworkers got away without tail vises for at least 100 years and so can you. You needn't leave much space to the right of your bench for the offcut. A long offcut is difficult to support here anyway. Tool Storage Space Hand tools aren't like hand-held power tools. Dropping them is generally disastrous. Metal tools are sensitive to rust, which can cause pits in polished metal blades. Wooden tools are sensitive to changes in humidity. Finding efficient ways of storing hand tools has been the effort of craftsmen for centuries. Rather than propose a revolutionary solution made from Medium-Density Fiberboard, a quick look back at what has been done might be wise. Images of pre-industrial shops clearly reveal a two-pronged approach to storing tools. Oft-used tools, generically referred to as "bench tools" because of their ever-present location on the bench, are shown stored on open shelves, or hung from hooks on the walls. Tool chests, frequently painted a blue green color (perhaps because the copper-based pigment was inexpensive), are shown in several images of pre-industrial shops. For many years I believed these chests were merely a convenient means of transporting a journeyman's tools as he "journeyed" from shop to shop. I was wrong. These chests are deceptively large and insanely heavy. And the term "journeyman" is an English corruption of the French word for "work day" (journee) referring not to the traveling nature of the worker but rather the way in which he is compensated for his work (for a day's work). These chests are a surpris ingly efficient way to store hand tools. Tools are easily accessed, safe from the hazards of the workshop, movable (with some difficulty) and the chest is unobtrusive. Made correctly, the chest's tight-fitting lids seem to protect the contents from rust. Popular Woodworking has offered a variety of plans for tool chests and wall-hung cabinets. One advantage of a traditional tool chest is that it can be relocated seasonally if necessary. If we define the "bench tools" properly and narrowly as those tools used almost continuously, rust should not be a problem. But great changes in humidity or temperature require us to reconsider the whole concept of bench tools. A fine tool chest may make an excellent window seat or coffee table. Tool chests from the 18th century are often indistinguishable from blanket chests. So why not put one in your bedroom? Tools required for a day's work could be unpacked and hung on walls or laid on open shelve s only to be returned at the end of a day's work with no great loss in efficiency and some significant gain in peace of mind. Lumber Storage Space Planing and sawing by hand forces you to read the grain, and feel its movement, variations in density, etc. I'm not one of those people who falls in love with wood or its grain. But a thorough familiarity with the material is inescapable. Before too long, every hand tool user develops preferences for certain lumber species, air-dried stock as opposed to kiln dried or steamed, and even specific cuts of wood such as quartersawn, plainsawn heart wood, flitches, etc. Consequently, and without exception, the First, place your bench against a wall. A 2' x 8' bench is, in my opinion, the minumum amount of space necessary for the bench. You don't want to strike the wall with your jointer plane. Put the end of your bench 2' from the wall - and it's a good place for a trash can. An anti-fatigue mat in front of your bench is an essential part of your shop. It gives you sure footing and is good for your back, too. Set aside 2' of space in front of your bench for ripping at the sawhorses. Add 1' to the right of the bench for crosscutting. popularwoodworking.com I 103 |