Popular Woodworking 2006-06 № 155, страница 76

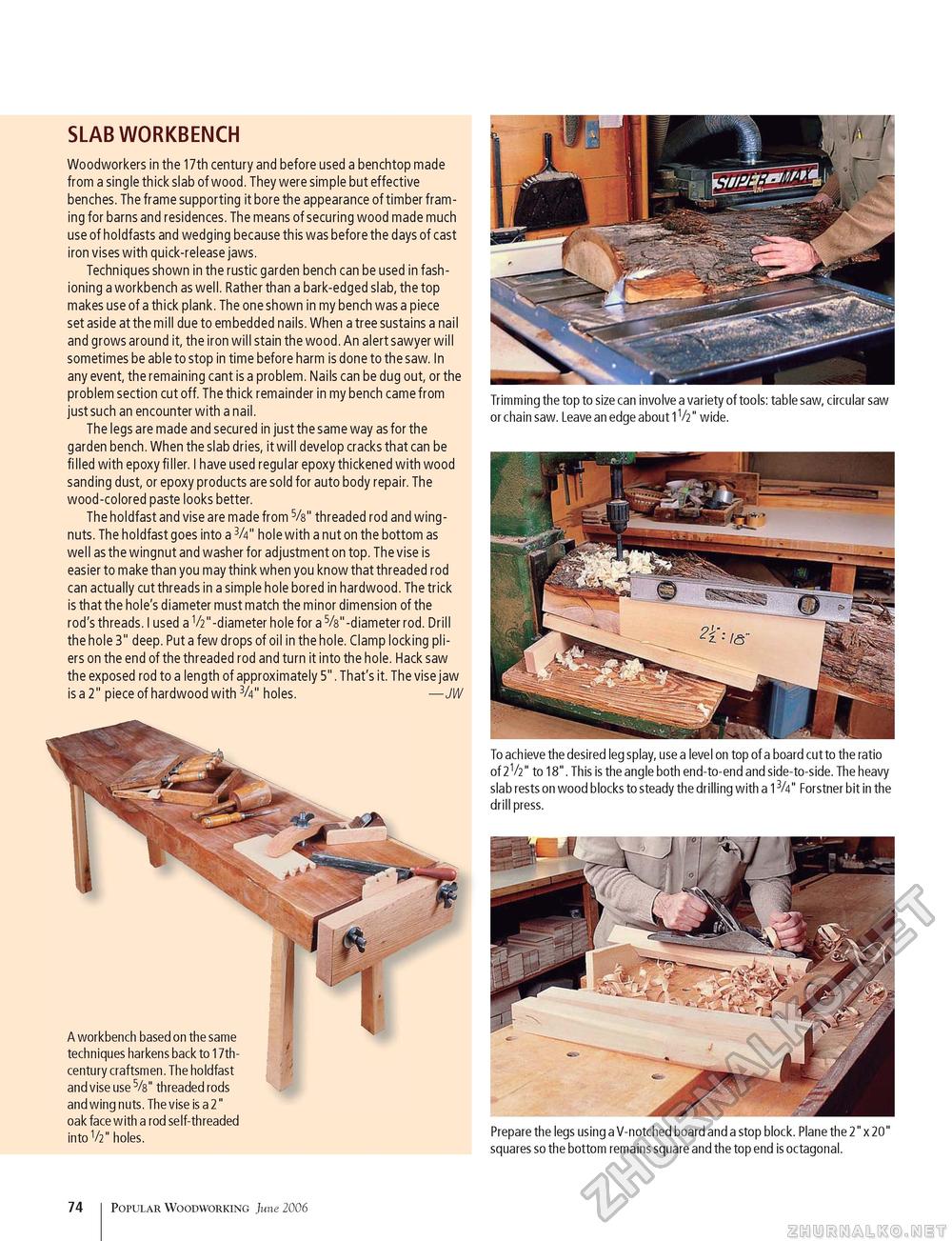

SLAB WORKBENCH Woodworkers in the 17th century and before used a benchtop made from a single thick slab of wood. They were simple but effective benches. The frame supporting it bore the appearance of timber framing for barns and residences. The means of securing wood made much use of holdfasts and wedging because this was before the days of cast iron vises with quick-release jaws. Techniques shown in the rustic garden bench can be used in fashioning a workbench as well. Rather than a bark-edged slab, the top makes use of a thick plank. The one shown in my bench was a piece set aside at the mill due to embedded nails. When a tree sustains a nail and grows around it, the iron will stain the wood. An alert sawyer will sometimes be able to stop in time before harm is done to the saw. In any event, the remaining cant is a problem. Nails can be dug out, or the problem section cut off. The thick remainder in my bench came from just such an encounter with a nail. The legs are made and secured in just the same way as for the garden bench. When the slab dries, it will develop cracks that can be filled with epoxy filler. I have used regular epoxy thickened with wood sanding dust, or epoxy products are sold for auto body repair. The wood-colored paste looks better. The holdfast and vise are made from 5/s" threaded rod and wing-nuts. The holdfast goes into a 3/4" hole with a nut on the bottom as well as the wingnut and washer for adjustment on top. The vise is easier to make than you may think when you know that threaded rod can actually cut threads in a simple hole bored in hardwood. The trick is that the hole's diameter must match the minor dimension of the rod's threads. I used a V2"-diameter hole for a 5/s"-diameter rod. Drill the hole 3" deep. Put a few drops of oil in the hole. Clamp locking pliers on the end of the threaded rod and turn it into the hole. Hack saw the exposed rod to a length of approximately 5". That's it. The vise jaw is a 2" piece of hardwood with 3/4" holes. — JW A workbench based on the same techniques harkens back to 17th-century craftsmen. The holdfast and vise use 5/s" threaded rods and wing nuts. The vise is a 2" oak face with a rod self-threaded into V2" holes. Trimming the top to size can involve a variety of tools: table saw, circular saw or chain saw. Leave an edge about 1V2" wide. To ach ieve the desired leg splay, use a level on top of a board cut to the ratio of 2V2" to 18". This is the angle both end-to-end and side-to-side. The heavy slab rests on wood blocks to steady the drilling with a 13/4" Forstner bit in the drill press. Prepare the legs using a V-notched board and a stop block. Plane the 2" x 20" squares so the bottom remains square and the top end is octagonal. 74 Popular Woodworking June 2006 |