Popular Woodworking 2006-06 № 155, страница 94

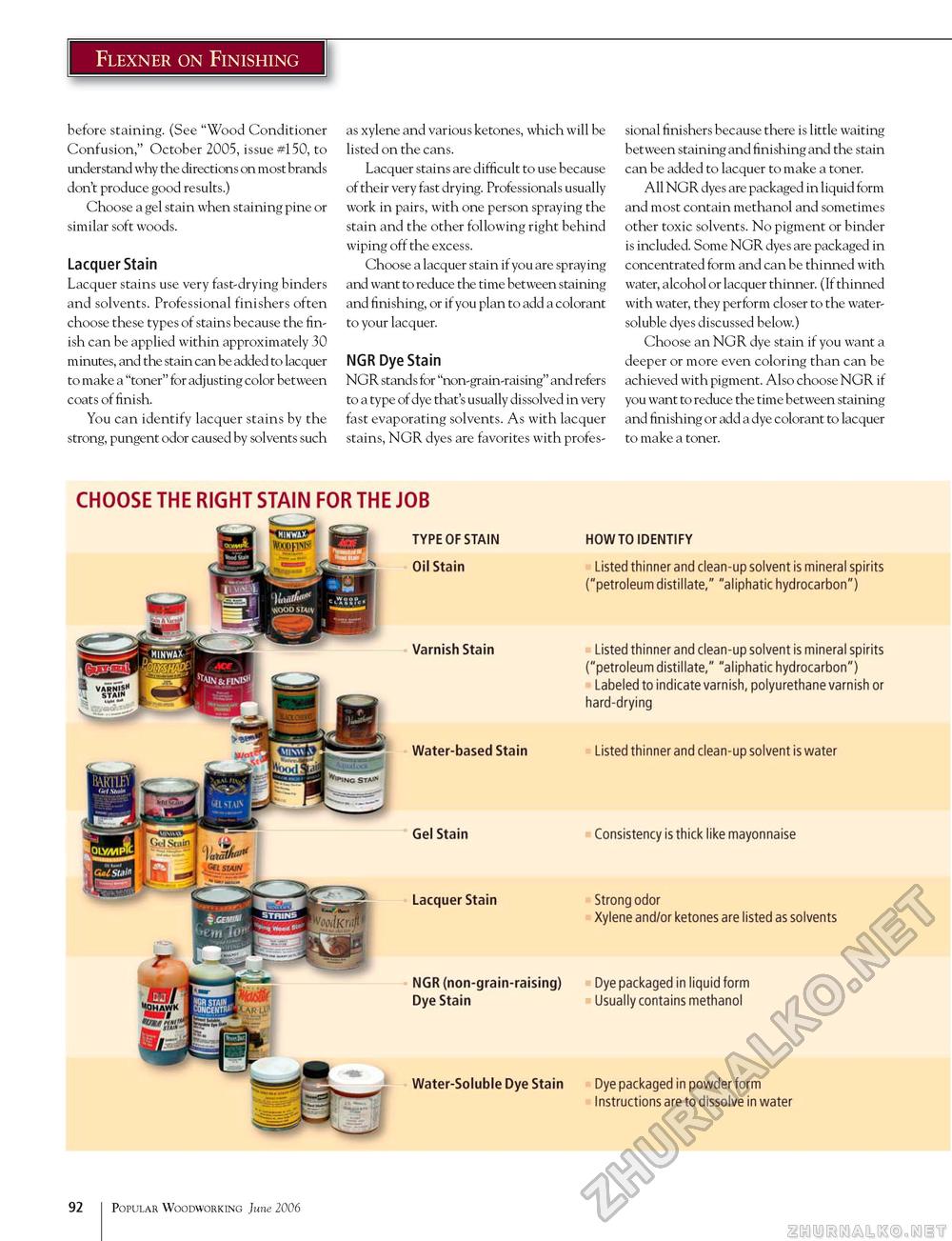

Flexner on Finishing before staining. (See "Wood Conditioner Confusion," October 2005, issue #150, to understand why the directions on most brands don't produce good results.) Choose a gel stain when staining pine or similar soft woods. Lacquer Stain Lacquer stains use very fast-drying binders and solvents. Professional finishers often choose these types of stains because the finish can be applied within approximately 30 minutes, and the stain can be added to lacquer to make a "toner" for adjusting color between coats of finish. You can identify lacquer stains by the strong, pungent odor caused by solvents such as xylene and various ketones, which will be listed on the cans. Lacquer stains are difficult to use because of their very fast drying. Professionals usually work in pairs, with one person spraying the stain and the other following right behind wiping off the excess. Choose a lacquer stain if you are spraying and want to reduce the time between staining and finishing, or if you plan to add a colorant to your lacquer. NGR Dye Stain NGR stands for "non-grain-raising" and refers to a type of dye that's usually dissolved in very fast evaporating solvents. As with lacquer stains, NGR dyes are favorites with profes sional finishers because there is little waiting between staining and finishing and the stain can be added to lacquer to make a toner. All NGR dyes are packaged in liquid form and most contain methanol and sometimes other toxic solvents. No pigment or binder is included. Some NGR dyes are packaged in concentrated form and can be thinned with water, alcohol or lacquer thinner. (If thinned with water, they perform closer to the water-soluble dyes discussed below.) Choose an NGR dye stain if you want a deeper or more even coloring than can be achieved with pigment. Also choose NGR if you want to reduce the time between staining and finishing or add a dye colorant to lacquer to make a toner. 92 Popular Woodworking June 2006 |