Popular Woodworking 2006-08 № 156, страница 23

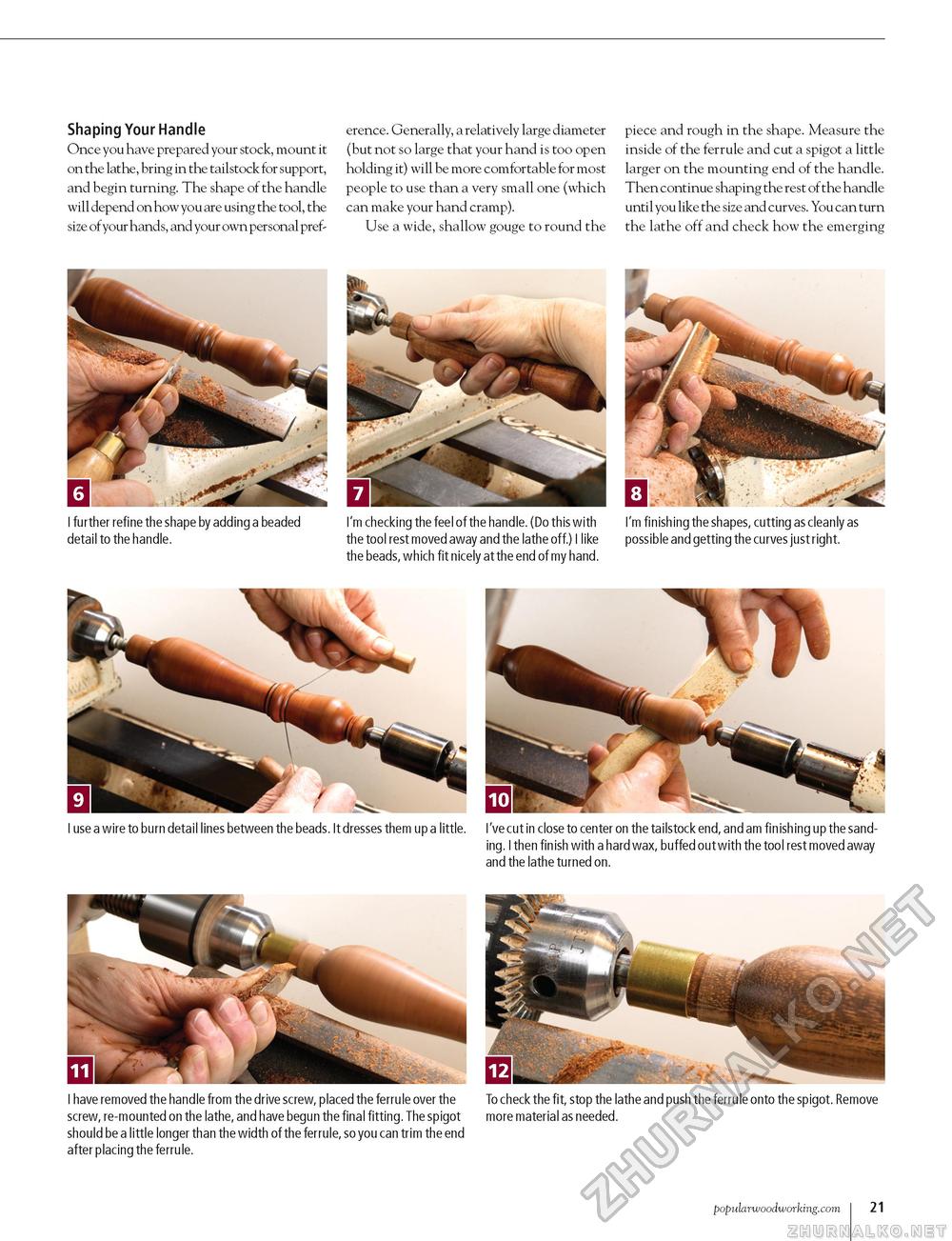

Shaping Your Handle Once you have prepared your stock, mount it on the lathe, bring in the tailstock for support, and begin turning. The shape of the handle will depend on how you are using the tool, the size ofyour hands, and your own personal pref erence. Generally, a relatively large diameter (but not so large that your hand is too open holding it) will be more comfortable for most people to use than a very small one (which can make your hand cramp). Use a wide, shallow gouge to round the piece and rough in the shape. Measure the inside of the ferrule and cut a spigot a little larger on the mounting end of the handle. Then continue shaping the rest of the handle until you like the size and curves. You can turn the lathe off and check how the emerging I further refine the shape by adding a beaded I'm checking the feel of the handle. (Do this with I'm finishing the shapes, cutting as cleanly as detail to the handle. the tool rest moved away and the lathe off.) I like possible and getting the curves just right. the beads, which fit nicely at the end of my hand. I use a wire to burn detail lines between the beads. It dresses them up a little. I've cut in close to center on the tailstock end, and am finishing up the sanding. I then finish with a hard wax, buffed out with the tool rest moved away and the lathe turned on. I have removed the handle from the drive screw, placed the ferrule over the To check the fit, stop the lathe and push the ferrule onto the spigot. Remove screw, re-mounted on the lathe, and have begun the final fitting. The spigot more material as needed. should be a little longer than the width of the ferrule, so you can trim the end after placing the ferrule. popularwoodworking.com I 21 |