Popular Woodworking 2006-10 № 157, страница 6

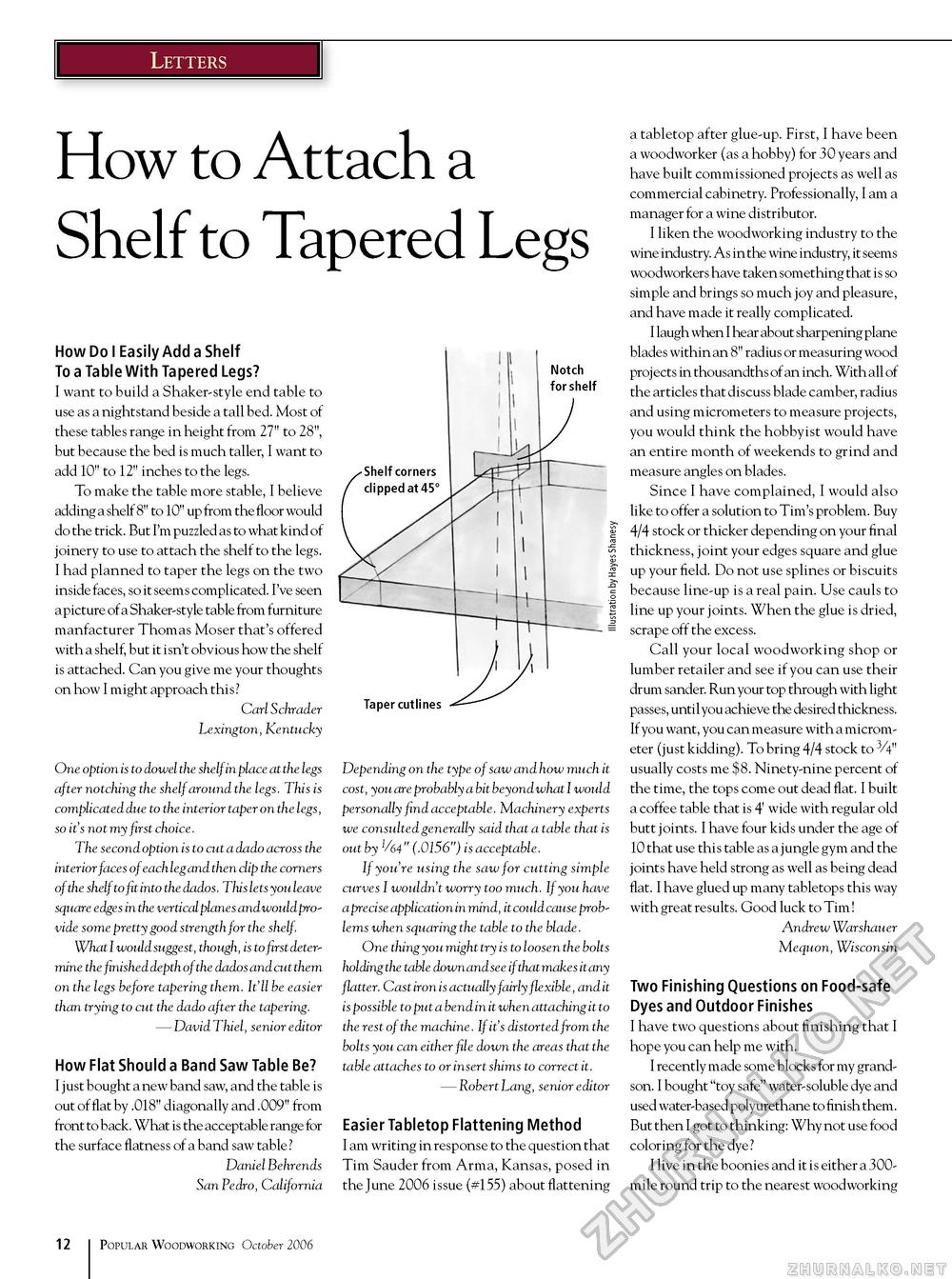

Letters How to Attach a Shelf to Tapered Legs How Do I Easily Add a Shelf To a Table With Tapered Legs? I want to build a Shaker-style end table to use as a nightstand beside a tall bed. Most of these tables range in height from 27" to 28", but because the bed is much taller, I want to add 10" to 12" inches to the legs. To make the table more stable, I believe adding a shelf 8" to 10" up from the floor would do the trick. But I'm puzzled as to what kind of joinery to use to attach the shelf to the legs. I had planned to taper the legs on the two inside faces, so it seems complicated. I've seen a picture of a Shaker-style table from furniture manfacturer Thomas Moser that's offered with a shelf, but it isn't obvious how the shelf is attached. Can you give me your thoughts on how I might approach this? Carl Schrader Lexington, Kentucky One option is to dowel the shelf in place at the legs after notching the shelf around the legs. This is complicated due to the interior taper on the legs, so it's not my first choice. The second option is to cut a dado across the interior faces of each leg and then clip the corners of the shelf to fit into the dados. This lets you leave square edges in the vertical planes and would provide some pretty good strength for the shelf. What I would suggest, though, is to first determine the finished depth of the dados and cut them on the legs before tapering them. It'll be easier than trying to cut the dado after the tapering. — David Thiel, senior editor How Flat Should a Band Saw Table Be? I just bought a new band saw, and the table is out of flat by .018" diagonally and .009" from front to back. What is the acceptable range for the surface flatness of a band saw table ? Daniel Behrends San Pedro, California Notch for shelf Taper cutlines Depending on the type of saw and how much it cost, you are probably a bit beyond what I would personally find acceptable. Machinery experts we consulted generally said that a table that is out by 1/64" (.0156") is acceptable. If you're using the saw for cutting simple curves I wouldn't worry too much. If you have a precise application in mind, it could cause problems when squaring the table to the blade. One thing you might try is to loosen the bolts holding the table down and see if that makes it any flatter. Cast iron is actually fairly flexible, and it is possible to put a bend in it when attaching it to the rest of the machine. If it's distorted from the bolts you can either file down the areas that the table attaches to or insert shims to correct it. — Robert Lang, senior editor Easier Tabletop Flattening Method I am writing in response to the question that Tim Sauder from Arma, Kansas, posed in the June 2006 issue (#155) about flattening a tabletop after glue-up. First, I have been a woodworker (as a hobby) for 30 years and have built commissioned projects as well as commercial cabinetry. Professionally, I am a manager for a wine distributor. I liken the woodworking industry to the wine industry. As in the wine industry, it seems woodworkers have taken something that is so simple and brings so much joy and pleasure, and have made it really complicated. I laugh when I hear about sharpening plane blades within an 8" radius or measuring wood proj ects in thousandths of an inch. With all of the articles that discuss blade camber, radius and using micrometers to measure projects, you would think the hobbyist would have an entire month of weekends to grind and measure angles on blades. Since I have complained, I would also like to offer a solution to Tim's problem. Buy 4/4 stock or thicker depending on your final thickness, joint your edges square and glue up your field. Do not use splines or biscuits because line-up is a real pain. Use cauls to line up your joints. When the glue is dried, scrape off the excess. Call your local woodworking shop or lumber retailer and see if you can use their drum sander. Run your top through with light passes, until you achieve the desired thickness. If you want, you can measure with a micrometer (just kidding). To bring 4/4 stock to 3/4" usually costs me $8. Ninety-nine percent of the time, the tops come out dead flat. I built a coffee table that is 4' wide with regular old butt joints. I have four kids under the age of 10 that use this table as a jungle gym and the joints have held strong as well as being dead flat. I have glued up many tabletops this way with great results. Good luck to Tim! Andrew Warshauer Mequon, Wisconsin Two Finishing Questions on Food-safe Dyes and Outdoor Finishes I have two questions about finishing that I hope you can help me with. I recently made some blocks for my grandson. I bought "toy safe" water-soluble dye and used water-based polyurethane to finish them. But then I got to thinking: Why not use food coloring for the dye ? I live in the boonies and it is either a 300-mile round trip to the nearest woodworking 12 Popular Woodworking October 2006 |