Popular Woodworking 2006-11 № 158, страница 23

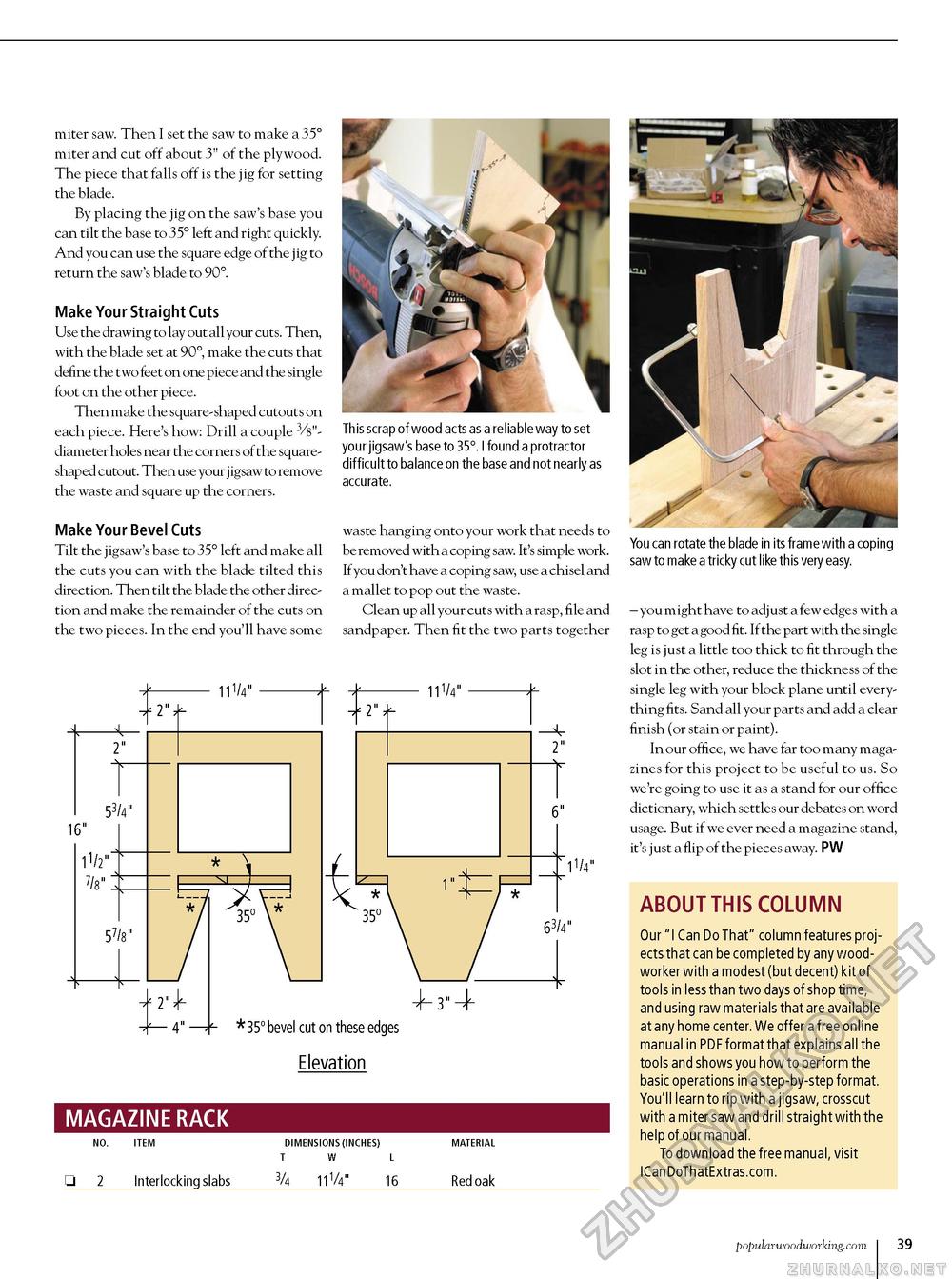

miter saw. Then I set the saw to make a 35° miter and cut off about 3" of the plywood. The piece that falls off is the jig for setting the blade. By placing the jig on the saw's base you can tilt the base to 35° left and right quickly. And you can use the square edge of the jig to return the saw's blade to 90°. Make Your Straight Cuts Use the drawing to lay out all your cuts. Then, with the blade set at 90°, make the cuts that define the two feet on one piece and the single foot on the other piece. Then make the square-shaped cutouts on each piece. Here's how: Drill a couple 3/s"-diameter holes near the corners of the square-shaped cutout. Then use your j igsaw to remove the waste and square up the corners. Make Your Bevel Cuts Tilt the jigsaw's base to 35° left and make all the cuts you can with the blade tilted this direction. Then tilt the blade the other direction and make the remainder of the cuts on the two pieces. In the end you'll have some This scrap of wood acts as a reliable way to set your jigsaw's base to 35°. I found a protractor difficult to balance on the base and not nearly as accurate. waste hanging onto your work that needs to be removed with a coping saw. It's simple work. If you don't have a coping saw, use a chisel and a mallet to pop out the waste. Clean up all your cuts with a rasp, file and sandpaper. Then fit the two parts together You can rotate the blade in its frame with a coping saw to make a tricky cut like this very easy. - you might have to adjust a few edges with a rasp to get a good fit. If the part with the single leg is just a little too thick to fit through the slot in the other, reduce the thickness of the single leg with your block plane until everything fits. Sand all your parts and add a clear finish (or stain or paint). In our office, we have far too many magazines for this project to be useful to us. So we're going to use it as a stand for our office dictionary, which settles our debates on word usage. But if we ever need a magazine stand, it's just a flip of the pieces away. PW ABOUT THIS COLUMN Our "I Can Do That" column features projects that can be completed by any woodworker with a modest (but decent) kit of tools in less than two days of shop time, and using raw materials that are available at any home center. We offer a free online manual in PDF format that explains all the tools and shows you how to perform the basic operations in a step-by-step format. You'll learn to rip with a jigsaw, crosscut with a miter saw and drill straight with the help of our manual. To download the free manual, visit ICanDoThatExtras.com. Elevation MAGAZINE RACK NO. ITEM DIMENSIONS (INCHES) MATERIAL T W L □ 2 Interlocking slabs 3k 11V4" 16 Red oak popularwoodworking.com i 39 |