Popular Woodworking 2006-11 № 158, страница 6

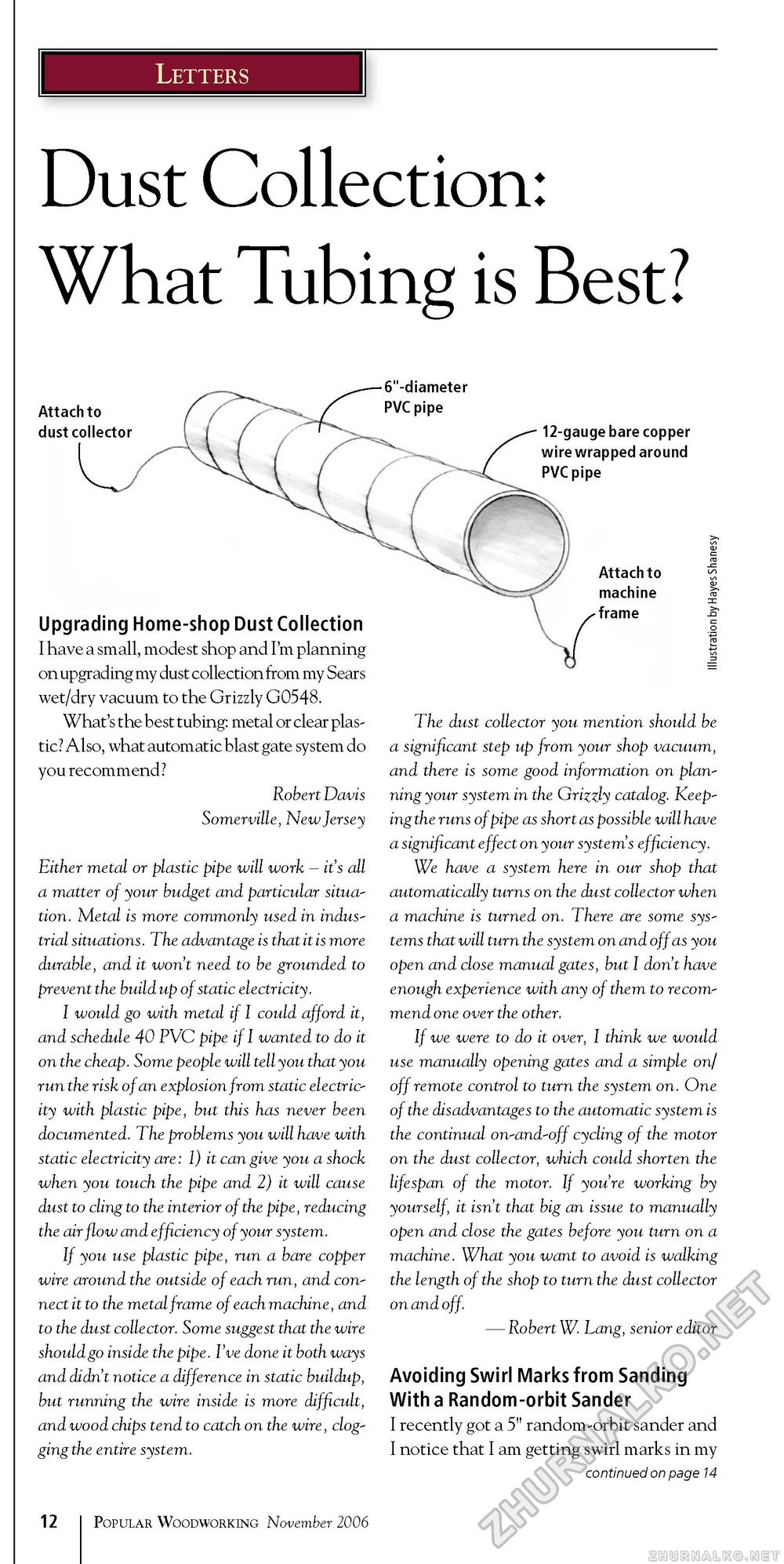

Letters Dust Collection: What Tubing is Best? Attach to dust collector 6"-diameter PVC pipe Upgrading Home-shop Dust Collection I have a small, modest shop and I'm planning on upgrading my dust collection from my Sears wet/dry vacuum to the Grizzly G0548. What's the best tubing: metal or clear plastic? Also, what automatic blast gate system do you recommend? Robert Davis Somerville, New Jersey Either metal or plastic pipe will work — it's all a matter of your budget and particular situation. Metal is more commonly used in industrial situations. The advantage is that it is more durable, and it won't need to be grounded to prevent the build up of static electricity. I would go with metal if I could afford it, and schedule 40 PVC pipe if I wanted to do it on the cheap. Some people will tell you that you run the risk of an explosion from static electricity with plastic pipe, but this has never been documented. The problems you will have with static electricity are: 1) it can give you a shock when you touch the pipe and 2) it will cause dust to cling to the interior of the pipe, reducing the air flow and efficiency of your system. If you use plastic pipe, run a bare copper wire around the outside of each run, and connect it to the metal frame of each machine, and to the dust collector. Some suggest that the wire should go inside the pipe. I've done it both ways and didn't notice a difference in static buildup, but running the wire inside is more difficult, and wood chips tend to catch on the wire, clogging the entire system. 12-gauge bare copper wire wrapped around PVCpipe Attach to machine frame The dust collector you mention should be a significant step up from your shop vacuum, and there is some good information on planning your system in the Grizzly catalog. Keeping the runs of pipe as short as possible will have a significant effect on your systems efficiency. We have a system here in our shop that automatically turns on the dust collector when a machine is turned on. There are some systems that will turn the system on and off as you open and close manual gates, but I don't have enough experience with any of them to recommend one over the other. If we were to do it over, I think we would use manually opening gates and a simple on/ off remote control to turn the system on. One of the disadvantages to the automatic system is the continual on-and-off cycling of the motor on the dust collector, which could shorten the lifespan of the motor. If you're working by yourself, it isn't that big an issue to manually open and close the gates before you turn on a machine. What you want to avoid is walking the length of the shop to turn the dust collector on and off. — Robert W. Lang, senior editor Avoiding Swirl Marks from Sanding With a Random-orbit Sander I recently got a 5" random-orbit sander and I notice that I am getting swirl marks in my continued on page 14 12 Popular Woodworking November 2006 |