Popular Woodworking 2006-12 № 159, страница 42

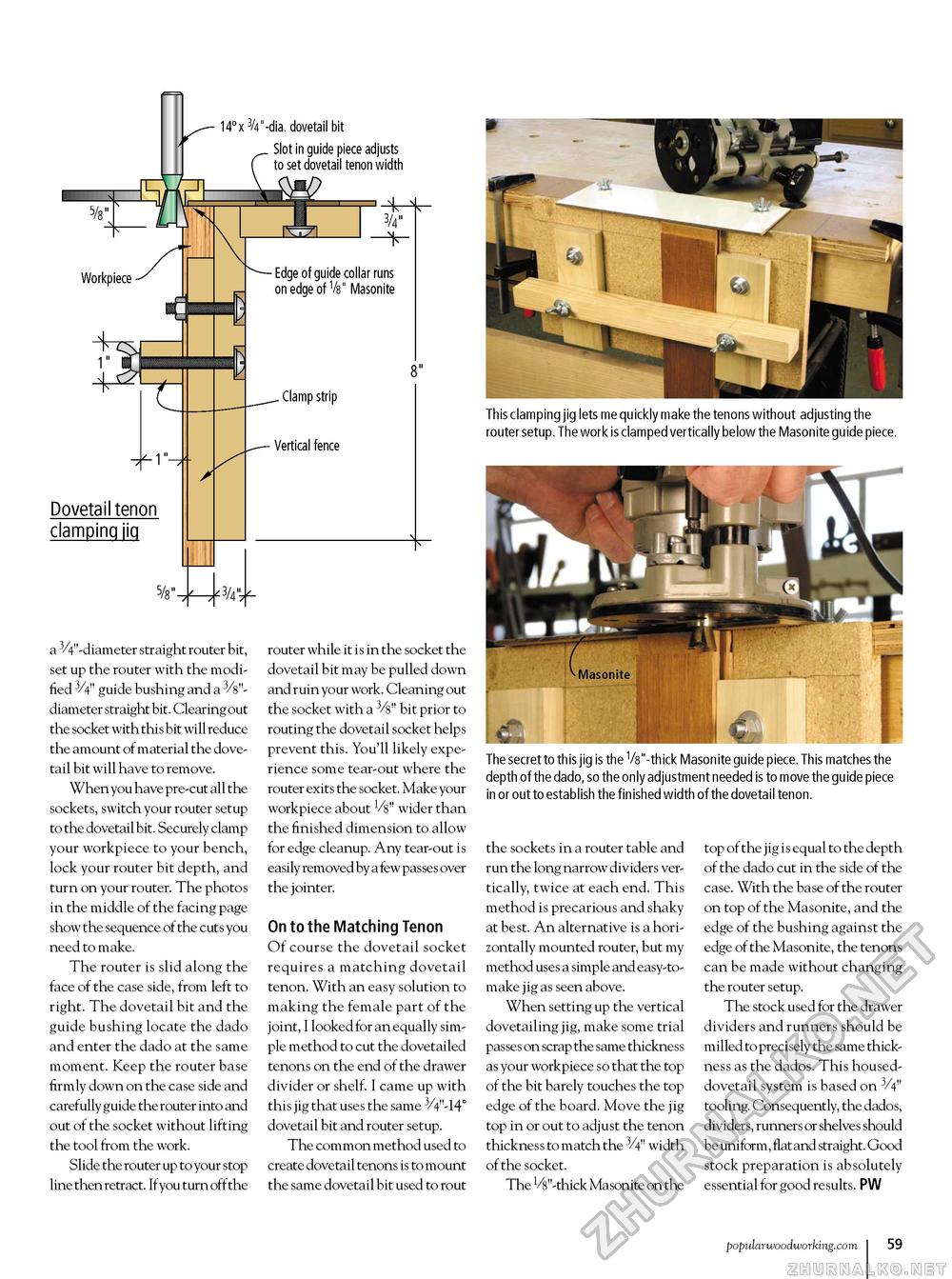

140x3/4"-dia. dovetail bit Slot in guide piece adjusts to set dovetail tenon width a 3/4"-diameter straight router bit, set up the router with the modified 3/4" guide bushing and a 3/8"-diameter straight bit. Clearing out the socket with this bit will reduce the amount of material the dovetail bit will have to remove. When you have pre-cut all the sockets, switch your router setup to the dovetail bit. Securely clamp your workpiece to your bench, lock your router bit depth, and turn on your router. The photos in the middle of the facing page show the sequence of the cuts you need to make. The router is slid along the face of the case side, from left to right. The dovetail bit and the guide bushing locate the dado and enter the dado at the same moment. Keep the router base firmly down on the case side and carefully guide the router into and out of the socket without lifting the tool from the work. Slide the router up to your stop line then retract. If you turn off the This clamping jig lets me quickly make the tenons without adjusting the router setup. The work is clamped vertically below the Masonite guide piece. router while it is in the socket the dovetail bit may be pulled down and ruin your work. Cleaning out the socket with a 3/8" bit prior to routing the dovetail socket helps prevent this. You'll likely experience some tear-out where the router exits the socket. Make your workpiece about V8" wider than the finished dimension to allow for edge cleanup. Any tear-out is easily removed by a few passes over the jointer. On to the Matching Tenon Of course the dovetail socket requires a matching dovetail tenon. With an easy solution to making the female part of the joint, I looked for an equally simple method to cut the dovetailed tenons on the end of the drawer divider or shelf. I came up with this jig that uses the same 3/4'-14° dovetail bit and router setup. The common method used to create dovetail tenons is to mount the same dovetail bit used to rout The secret to this jig is the 1/8"-thick Masonite guide piece. This matches the depth of the dado, so the only adjustment needed is to move the guide piece in or out to establish the finished width of the dovetail tenon. the sockets in a router table and run the long narrow dividers vertically, twice at each end. This method is precarious and shaky at best. An alternative is a horizontally mounted router, but my method uses a simple and easy-to-make jig as seen above. When setting up the vertical dovetailing jig, make some trial passes on scrap the same thickness as your workpiece so that the top of the bit barely touches the top edge of the board. Move the jig top in or out to adjust the tenon thickness to match the 3/4" width of the socket. The V8"-thick Masonite on the top of the jig is equal to the depth of the dado cut in the side of the case. With the base of the router on top of the Masonite, and the edge of the bushing against the edge of the Masonite, the tenons can be made without changing the router setup. The stock used for the drawer dividers and runners should be milled to precisely the same thickness as the dados. This housed-dovetail system is based on 3/4" tooling. Consequently, the dados, dividers, runners or shelves should be uniform, flat and straight. Good stock preparation is absolutely essential for good results. PW popularwoodworking.com i 59 |