Popular Woodworking 2006-12 № 159, страница 6

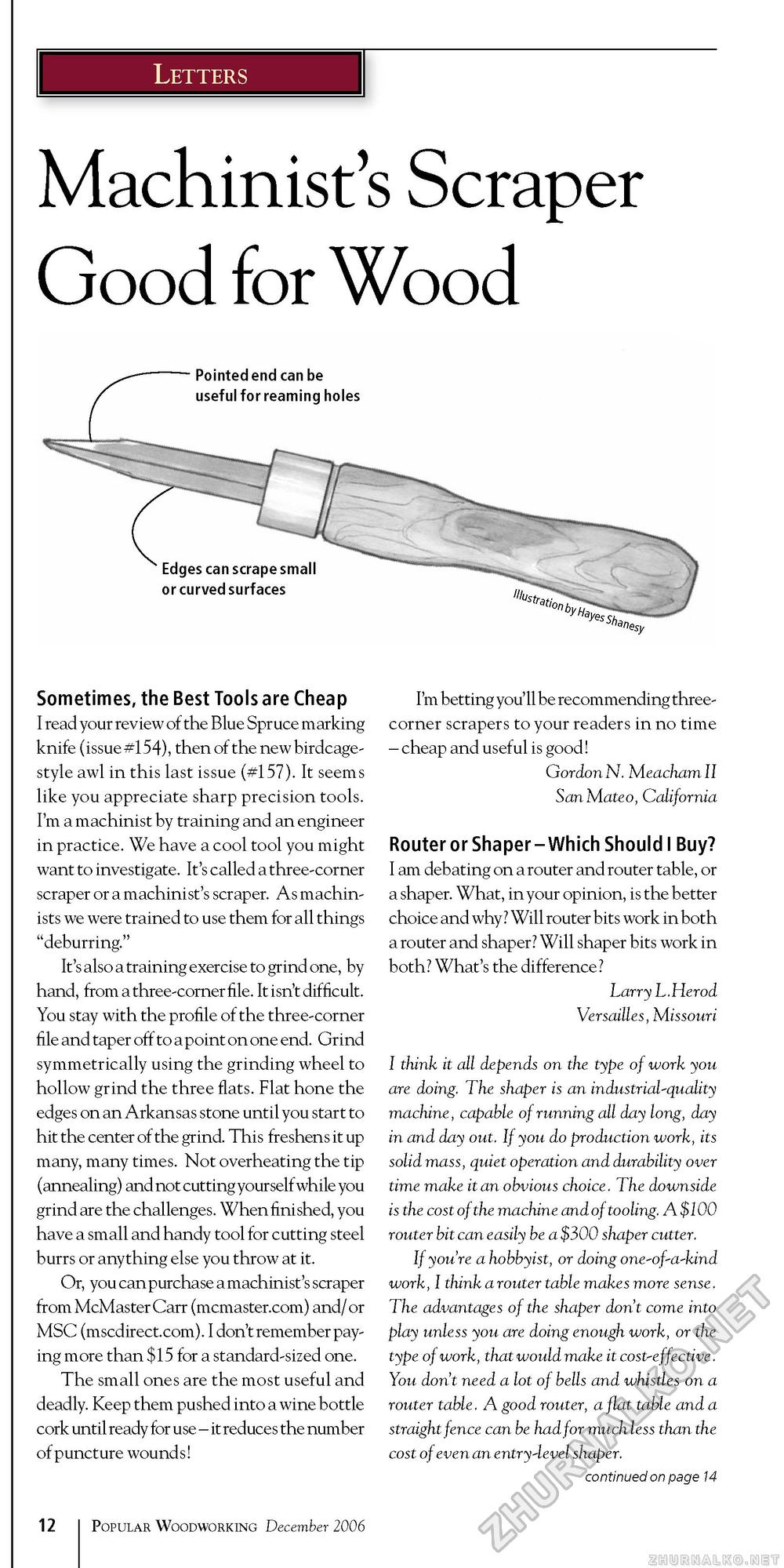

Letters Machinist's Scraper Good for Wood Pointed end can be useful for reaming holes ' Edges can scrape small or curved surfaces Sometimes, the Best Tools are Cheap I read your review of the Blue Spruce marking knife (issue #154), then of the new birdcage-style awl in this last issue (#157). It seems like you appreciate sharp precision tools. I'm a machinist by training and an engineer in practice. We have a cool tool you might want to investigate. It's called a three-corner scraper or a machinist's scraper. As machinists we were trained to use them for all things "deburring." It's also a training exercise to grind one, by hand, from a three-corner file. It isn't difficult. You stay with the profile of the three-corner file and taper off to a point on one end. Grind symmetrically using the grinding wheel to hollow grind the three flats. Flat hone the edges on an Arkansas stone until you start to hit the center of the grind. This freshens it up many, many times. Not overheating the tip (annealing) and not cutting yourself while you grind are the challenges. When finished, you have a small and handy tool for cutting steel burrs or anything else you throw at it. Or, you can purchase a machinist's scraper from McMaster Carr (mcmaster.com) and/ or MSC (mscdirect.com). I don't remember paying more than $15 for a standard-sized one. The small ones are the most useful and deadly. Keep them pushed into a wine bottle cork until ready for use - it reduces the number of puncture wounds! I'm betting you'll be recommending three-corner scrapers to your readers in no time - cheap and useful is good! Gordon N. Meacham II San Mateo, California Router or Shaper - Which Should I Buy? I am debating on a router and router table, or a shaper. What, in your opinion, is the better choice and why ? Will router bits work in both a router and shaper? Will shaper bits work in both? What's the difference? Larry L.Herod Versailles, Missouri I think it all depends on the type of work you are doing. The shaper is an industrial-quality machine, capable of running all day long, day in and day out. If you do production work, its solid mass, quiet operation and durability over time make it an obvious choice. The downside is the cost of the machine and of tooling. A $100 router bit can easily be a $300 shaper cutter. If you're a hobbyist, or doing one-of-a-kind work, I think a router table makes more sense. The advantages of the shaper don't come into play unless you are doing enough work, or the type of work, that would make it cost-effective. You don't need a lot of bells and whistles on a router table. A good router, a flat table and a straight fence can be had for much less than the cost of even an entry-level shaper. continued on page 14 12 Popular Woodworking December 2006 |