Popular Woodworking 2007-08 № 163, страница 37

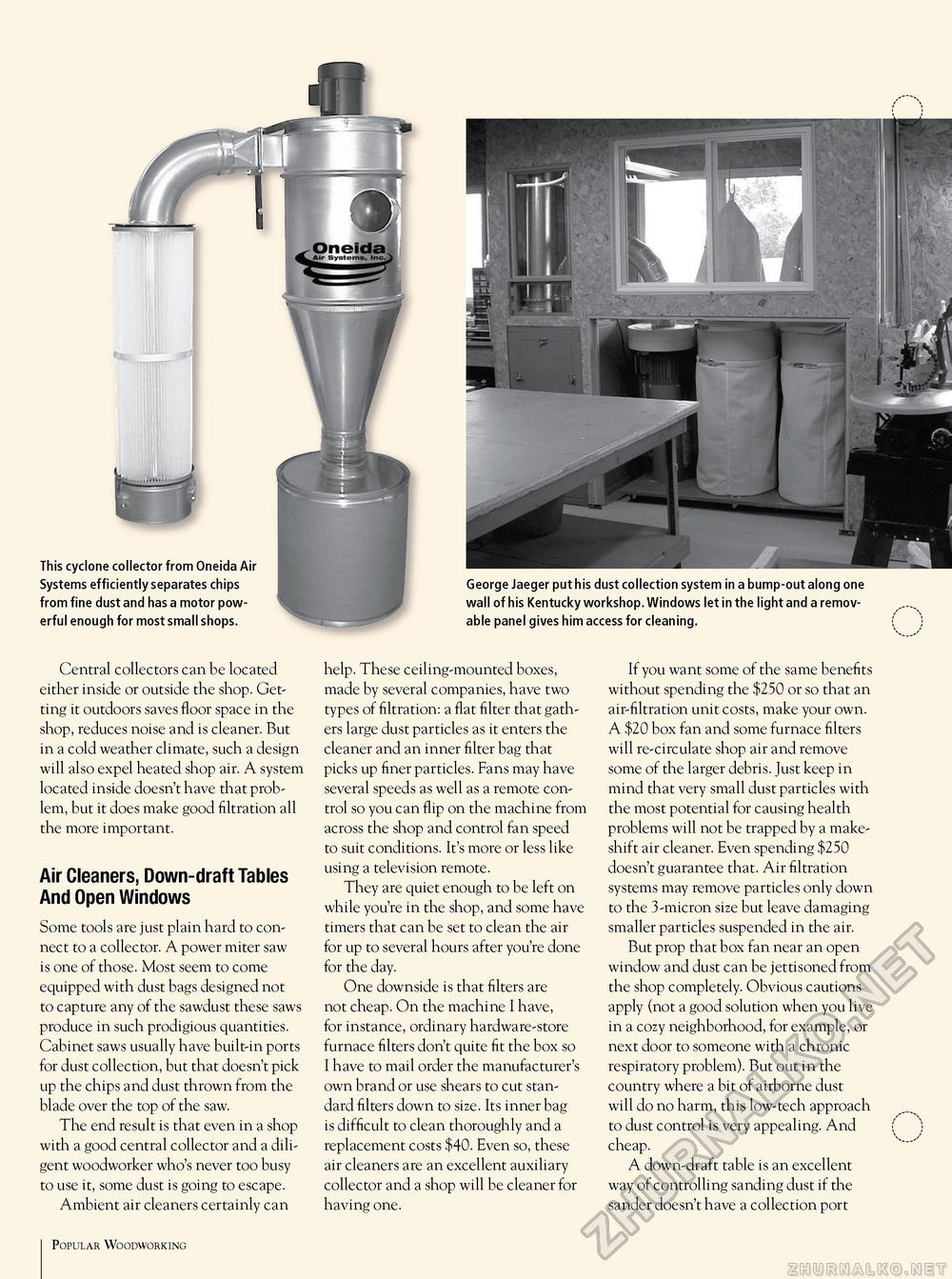

This cyclone collector from Oneida Air Systems efficiently separates chips from fine dust and has a motor pow erful enough for most small shops. George Jaeger put his dust collection system in a bump-out along one wall of his Kentucky workshop. Windows let in the light and a removable panel gives him access for cleaning. Central collectors can be located either inside or outside the shop. Getting it outdoors saves floor space in the shop, reduces noise and is cleaner. But in a cold weather climate, such a design will also expel heated shop air. A system located inside doesn't have that problem, but it does make good filtration all the more important. Air Cleaners, Down-draft Tables And Open Windows Some tools are just plain hard to connect to a collector. A power miter saw is one of those. Most seem to come equipped with dust bags designed not to capture any of the sawdust these saws produce in such prodigious quantities. Cabinet saws usually have built-in ports for dust collection, but that doesn't pick up the chips and dust thrown from the blade over the top of the saw. The end result is that even in a shop with a good central collector and a diligent woodworker who's never too busy to use it, some dust is going to escape. Ambient air cleaners certainly can Popular Woodworking help. These ceiling-mounted boxes, made by several companies, have two types of filtration: a flat filter that gathers large dust particles as it enters the cleaner and an inner filter bag that picks up finer particles. Fans may have several speeds as well as a remote control so you can flip on the machine from across the shop and control fan speed to suit conditions. It's more or less like using a television remote. They are quiet enough to be left on while you're in the shop, and some have timers that can be set to clean the air for up to several hours after you're done for the day. One downside is that filters are not cheap. On the machine I have, for instance, ordinary hardware-store furnace filters don't quite fit the box so I have to mail order the manufacturer's own brand or use shears to cut standard filters down to size. Its inner bag is difficult to clean thoroughly and a replacement costs $40. Even so, these air cleaners are an excellent auxiliary collector and a shop will be cleaner for having one. If you want some of the same benefits without spending the $250 or so that an air-filtration unit costs, make your own. A $20 box fan and some furnace filters will re-circulate shop air and remove some of the larger debris. Just keep in mind that very small dust particles with the most potential for causing health problems will not be trapped by a makeshift air cleaner. Even spending $250 doesn't guarantee that. Air filtration systems may remove particles only down to the 3-micron size but leave damaging smaller particles suspended in the air. But prop that box fan near an open window and dust can be jettisoned from the shop completely. Obvious cautions apply (not a good solution when you live in a cozy neighborhood, for example, or next door to someone with a chronic respiratory problem). But out in the country where a bit of airborne dust will do no harm, this low-tech approach to dust control is very appealing. And cheap. A down-draft table is an excellent way of controlling sanding dust if the sander doesn't have a collection port |