Popular Woodworking 2008-04 № 168, страница 14

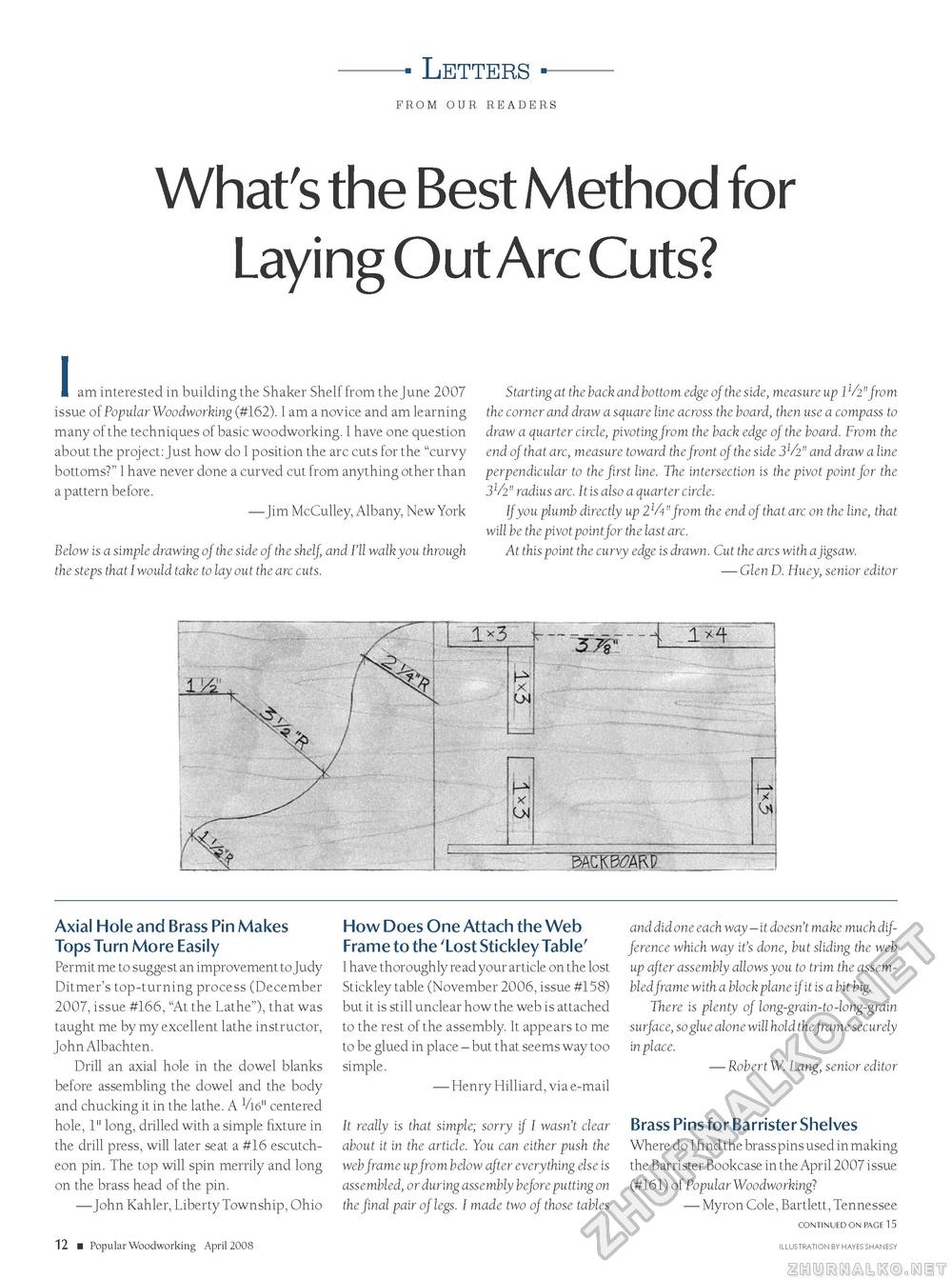

- Letters - FROM OUR READERS What's the Best Method for Laying Out Arc Cuts? I am interested in building the Shaker Shelf from the June 2007 issue of Popular Woodworking (#162). I am a novice and am learning many of the techniques of basic woodworking. I have one question about the project: Just how do I position the arc cuts for the "curvy bottoms?" I have never done a curved cut from anything other than a pattern before. —Jim McCulley, Albany, New York Below is a simple drawing of the side of the shelf, and I'll walk you through the steps that I would take to lay out the arc cuts. Starting at the back and bottom edge of the side, measure up 11/2" from the corner and draw a square line across the board, then use a compass to draw a quarter circle, pivoting from the back edge of the board. From the end of that arc, measure toward the front of the side 31/2" and draw a line perpendicular to the first line. The intersection is the pivot point for the 31/2" radius arc. It is also a quarter circle. If you plumb directly up 21/4" from the end of that arc on the line, that will be the pivot pointfor the last arc. At this point the curvy edge is drawn. Cut the arcs with a jigsaw. — Glen D. Huey, senior editor Axial Hole and Brass Pin Makes Tops Turn More Easily Permit me to suggest an improvement to Judy Ditmer's top-turning process (December 2007, issue #166, "At the Lathe"), that was taught me by my excellent lathe instructor, John Albachten. Drill an axial hole in the dowel blanks before assembling the dowel and the body and chucking it in the lathe. A Vi6" centered hole, 1" long, drilled with a simple fixture in the drill press, will later seat a #16 escutcheon pin. The top will spin merrily and long on the brass head of the pin. —John Kahler, Liberty Township, Ohio How Does One Attach the Web Frame to the 'Lost Stickley Table' I have thoroughly read your article on the lost Stickley table (November 2006, issue #158) but it is still unclear how the web is attached to the rest of the assembly. It appears to me to be glued in place - but that seems way too simple. — Henry Hilliard, via e-mail It really is that simple; sorry if I wasn't clear about it in the article. You can either push the web frame up from below after everything else is assembled, or during assembly before putting on the final pair of legs. I made two of those tables and did one each way—it doesn't make much difference which way it's done, but sliding the web up after assembly allows you to trim the assembled frame with a block plane if it is a bit big. There is plenty of long-grain-to-long-grain surface, so glue alone will hold the frame securely in place. — Robert W. Lang, senior editor Brass Pins for Barrister Shelves Where do I find the brass pins used in making the Barrister Bookcase in the April 2007 issue (#161) of Popular Woodworking? — Myron Cole, Bartlett, Tennessee CONTINUED ON PAGE 15 12 ■ Popular Woodworking April 2008 ILLUSTRATION BY HAYES SHANESY |