Popular Woodworking 2008-04 № 168, страница 89

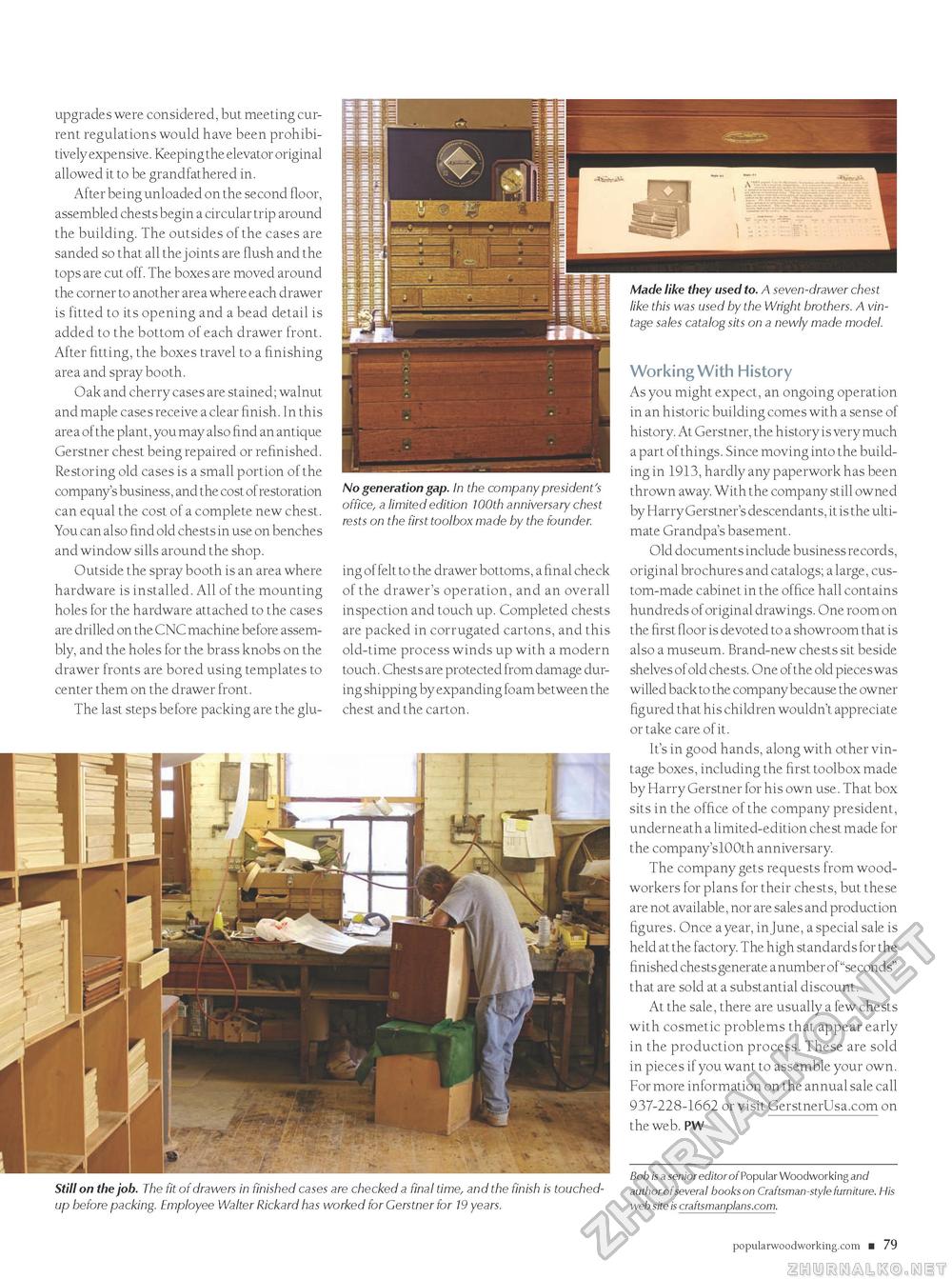

upgrades were considered, but meeting current regulations would have been prohibitively expensive. Keeping the elevator original allowed it to be grandfathered in. After being unloaded on the second floor, assembled chests begin a circular trip around the building. The outsides of the cases are sanded so that all the joints are flush and the tops are cut off. The boxes are moved around the corner to another area where each drawer is fitted to its opening and a bead detail is added to the bottom of each drawer front. After fitting, the boxes travel to a finishing area and spray booth. Oak and cherry cases are stained; walnut and maple cases receive a clear finish. In this area of the plant, you may also find an antique Gerstner chest being repaired or refinished. Restoring old cases is a small portion of the company's business, and the cost of restoration can equal the cost of a complete new chest. You can also find old chests in use on benches and window sills around the shop. Outside the spray booth is an area where hardware is installed. All of the mounting holes for the hardware attached to the cases are drilled on the CNC machine before assembly, and the holes for the brass knobs on the drawer fronts are bored using templates to center them on the drawer front. The last steps before packing are the glu- No generation gap. In the company president's office, a limited edition 100th anniversary chest rests on the first toolbox made by the founder. ing of felt to the drawer bottoms, a final check of the drawer's operation, and an overall inspection and touch up. Completed chests are packed in corrugated cartons, and this old-time process winds up with a modern touch. Chests are protected from damage during shipping by expanding foam between the chest and the carton. Still on the job. The fit of drawers in finished cases are checked a final time, and the finish is touched-up before packing. Employee Walter Rickard has worked for Gerstner for 19 years. Made like they used to. A seven-drawer chest like this was used by the Wright brothers. A vintage sales catalog sits on a newly made model. Working With History As you might expect, an ongoing operation in an historic building comes with a sense of history. At Gerstner, the history is very much a part of things. Since moving into the building in 1913, hardly any paperwork has been thrown away. With the company still owned by Harry Gerstner's descendants, it is the ultimate Grandpa's basement. Old documents include business records, original brochures and catalogs; a large, custom-made cabinet in the office hall contains hundreds of original drawings. One room on the first floor is devoted to a showroom that is also a museum. Brand-new chests sit beside shelves of old chests. One of the old pieces was willed back to the company because the owner figured that his children wouldn't appreciate or take care of it. It's in good hands, along with other vintage boxes, including the first toolbox made by Harry Gerstner for his own use. That box sits in the office of the company president, underneath a limited-edition chest made for the company's100th anniversary. The company gets requests from woodworkers for plans for their chests, but these are not available, nor are sales and production figures. Once a year, in June, a special sale is held at the factory. The high standards for the finished chests generate a number of "seconds" that are sold at a substantial discount. At the sale, there are usually a few chests with cosmetic problems that appear early in the production process. These are sold in pieces if you want to assemble your own. For more information on the annual sale call 937-228-1662 or visit GerstnerUsa.com on the web. PW Bob is a senior editor of Popular Woodworking and author of several books on Craftsman-style furniture. His web site is craftsmanplans.com. popularwoodworking.com ■ 79 CIRCLE #100 ON FREE INFORMATION CARD. |