Popular Woodworking 2008-06 № 169, страница 63

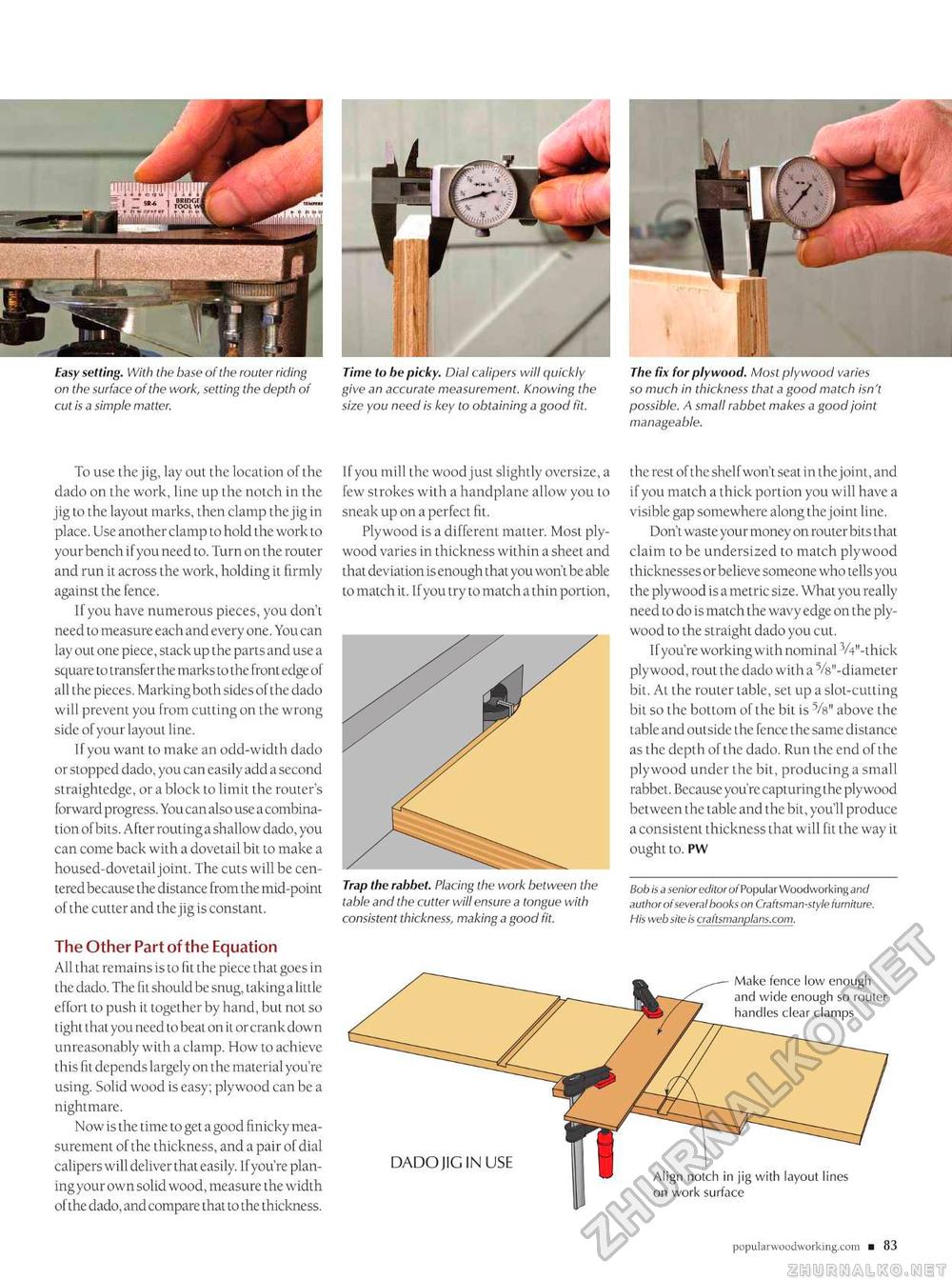

Easy selling. With the base ofthe router riding on the surface ofthe work, setting the depth of cut is a simple matter. Time to be picky. Dial calipers will quickly give an accurate measurement. Knowing the size you need is key to obtaining a good fit. The fix for plywood. Most plywood varies so much in thickness that a good match isn't possible. A small rabbet makes a good joint manageable. To use the jig, lay out the location ofthe dado on the work, line up the notch in the jig to the layout marks, then clamp the jig in place. Use another clamp to hold the work to your bench if you need to. Turn on the router and run it across the work, holding it firmly against the fence. If you have numerous pieces, you don't need to measure each and every one. You can lay out one piece, stack up the parts and use a square to transfer the marks to the front edge of all the pieces. Marking both sides ofthe dado will prevent you from cutting on the wrong side of your layout line. If you want to make an odd-width dado or stopped dado, you can easily add a second straightedge, or a block to limit the router's forward progress. You can also use a combination of bits. After routing a shallow dado, you can come back with a dovetail bit to make a housed-dovetail joint. The cuts will be centered because the distance from the mid-point of the cutter and the jig is constant. The Other Part ofthe Equation All that remains is to fit the piece that goes in the dado. The fit should be snug, taking a 1 iule effort to push it together by hand, but not so tight that you need to beat on it or crank down unreasonably with a clamp. How to achieve this fit depends largely on the material you're using. Solid wood is easy; plywood can be a nightmare. Now is the time to get a good finicky measurement ofthe thickness, and a pair of dial calipers will deliver that easily. If you're planing your own solid wood, measure the width ofthe dado, and compare that to the thickness. If you mill the wood just slightly oversize, a few strokes with a handplane allow you to sneak up on a perfect fit. Plywood is a different matter. Most plywood varies in thickness within a sheet and that deviation is enough that you won't be able to match it. If you try to match a thin portion. Trap the rabbet. Placing the work between the table and the cutter will ensure a tongue with consistent thickness, making a good fit. the rest of theshelfwon't seat in thejoint, and if you match a thick portion you will have a visible gap somewhere along thejoint line. Don't waste your money on router bits that claim to be undersized to match plywood thicknesses or believe someone who tells you the plywood is a metric size. What you really need to do is match the wavy edge on the plywood to the straight dado you cut. If you're working with nominal 3/-t "-thick plywood, rout the dado with a Vs'-diameter bit. At the router table, set up a slot-cutting bit so the bottom ofthe bit is 5/s" above the table and outside the fence the same distance as the depth ofthe dado. Run the end of the plywood under the bit, producing a small rabbet. Because you're capturing the plywood between the table and the bit, you'll produce a consistent thickness that will fit the way it ought to. PW Bob is a senior editor (/Popular Woodworking and author of several books on Craftsman-style furniture. His web site is craftsmanplans.com. Make fence low enough and wide enough so router handles clear clamps DADO JIG IN USE Align notch in jig with layout lines on work surface |