Popular Woodworking 2008-08 № 170, страница 60

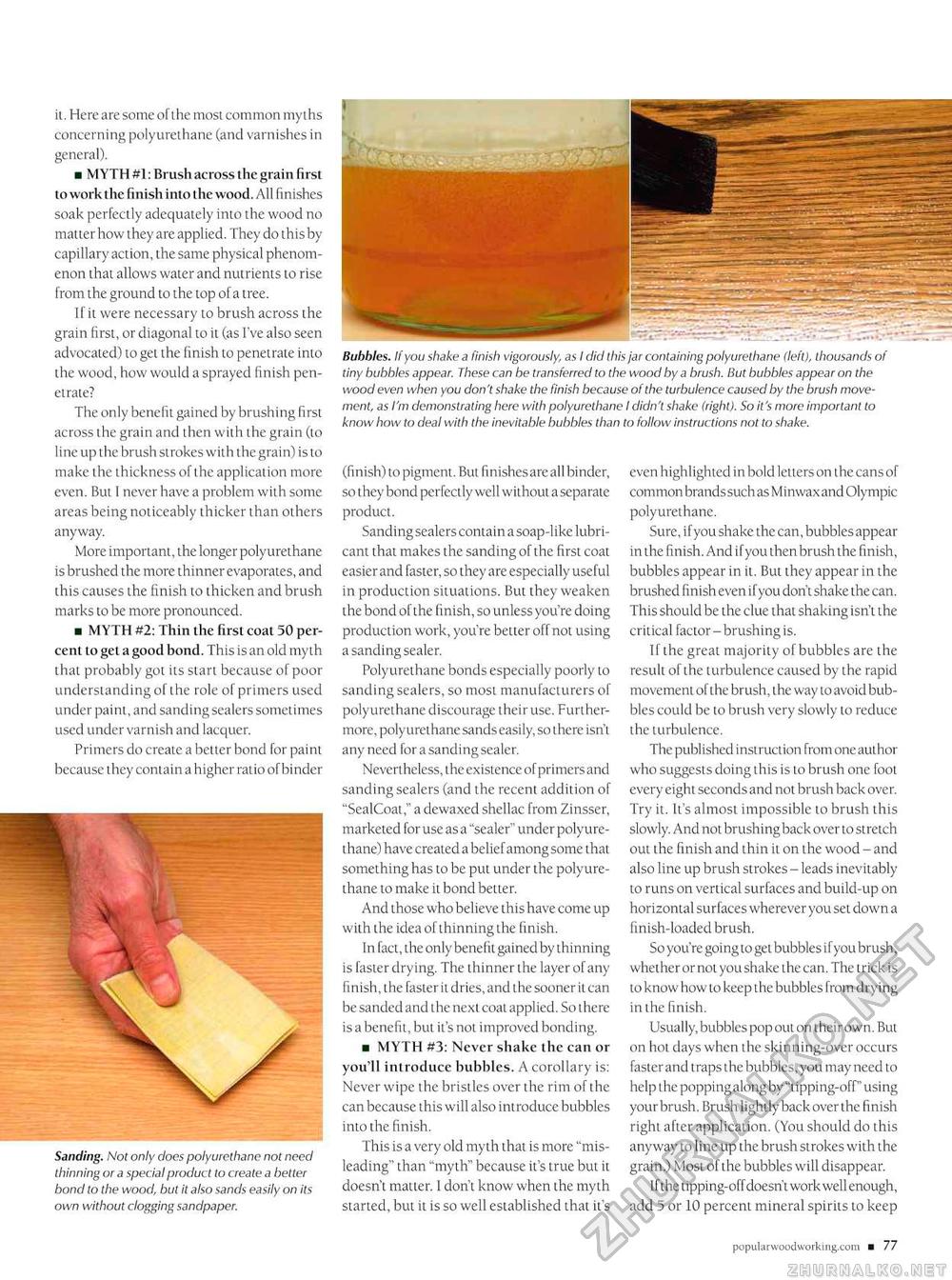

it. Here are some of the most common myths concerning polyurethane (and varnishes in general). ■ MYTH #1: Brush across the grain first to work the finish into the wood. All finishes soak perfectly adequately into the wood no matter how they are applied. They do this by capillary action, the same physical phenomenon that allows water and nutrients to rise from the ground to the top of a tree. If it were necessary to brush across the grain first, or diagonal to it (as I've also seen advocated) to get the finish to penetrate into the wood, how would a sprayed finish penetrate? The only benefit gained by brushing first across the grain and then with the grain (to line up the brush strokes with the grain) is to make the thickness of the application more even. But I never have a problem with some areas being noticeably thicker than others anyway. More important, the longer polyurethane is brushed the more thinner evaporates, and this causes the finish to thicken and brush marks to be more pronounced. ■ MYTH #2: Thin the first coat 50 percent to gel a good bond. This is an old myth that probably got its start because of poor understanding of the role of primers used under paint, and sanding sealers sometimes used under varnish and lacquer. Primers do create a better bond for paint because they contain a higher ratio of binder Bubbles. If you shake a finish vigorously, as I did this jar containing polyurethane (left), thousands ol tiny bubbles appear. These can be transferred to the wood by a brush. But bubbles appear on the wood even when you don't shake the finish because of the turbulence caused by the brush movement, as I'm demonstrating here with polyurethane I didn't shake (right). So it's more important to know how to deal with the inevitable bubbles than to follow instructions not to shake. Sanding. Not only does polyurethane not need thinning or a special product to create a better bond to the wood, but it also sands easily on its own without clogging sandpaper. (finish) to pigment. But finishesare all binder, so they bond perfectly well without a separate product. Sanding sealers contain a soap-like lubricant that makes the sanding of the first coat easier and faster, so they are especially useful in production situations. But they weaken the bond of the finish, so unless you're doing production work, you're better off not using a sanding sealer. Polyurethane bonds especially poorly to sanding sealers, so most manufacturers of polyurethane discourage their use. Furthermore, polyurethane sands easily, so there isn't any need for a sanding sealer. Nevertheless, the existence of primers and sanding sealers (and the recent addition of "SealCoat," a dewaxed shellac from Zinsser, marketed for use as a "sealer" under polyurethane) have created a belief among some that something has to be put under the polyurethane to make it bond better. And those who believe this have come up with the idea of thinning the finish. In fact, the only benefit gained by thinning is faster drying. The thinner the layer of any finish, the faster it dries, and the sooner it can be sanded and the next coal applied. So there is a benefit, but it's not improved bonding. ■ MYTH #3: Never shake the can or you'll introduce bubbles. A corollary is: Never wipe the bristles over the rim of the can because this will also introduce bubbles into the finish. This is a very old myth that is more "misleading" than "myth" because it's true but it doesn't matter. 1 don't know when the myth started, but it is so well established that it's even highlighted in bold letters on the cans of common brands such asMinwaxand Olympic polyurethane. Sure, if you shake the can, bubbles appear in the finish. And if you then brush the finish, bubbles appear in it. But they appear in the brushed finish even if you don't shake the can. This should be the clue that shaking isn't the critical factor - brushing is. If the great majority of bubbles are the result of the turbulence caused by the rapid movement of the brush, the way to avoid bubbles could be to brush very slowly to reduce the turbulence. The published instruction fromoneaulhor who suggests doing this is to brush one foot every eight seconds and not brush back over. Try it. It's almost impossible to brush this slowly. And not brushing back over to stretch out the finish and thin it on the wood - and also line up brush strokes - leads inevitably to runs on vertical surfaces and build-up on horizontal surfaces wherever you set down a finish-loaded brush. So you're going to get bubbles if you brush, whether or not you shake the can. The trick is to know how to keep the bubbles from drying in the finish. Usually, bubbles pop out on theirown. But on hot days when the skinning-over occurs faster and traps the bubbles, you may need to help the popping along by "tipping-off" using your brush. Brush lightly back over the finish right after application. (You should do this anyway to line up the brush strokes with the grain.) Most of the bubbles will disappear. If the tipping-off doesn't work well enough, add 5 or 10 percent mineral spirits to keep |