Popular Woodworking 2009-02 № 174, страница 53

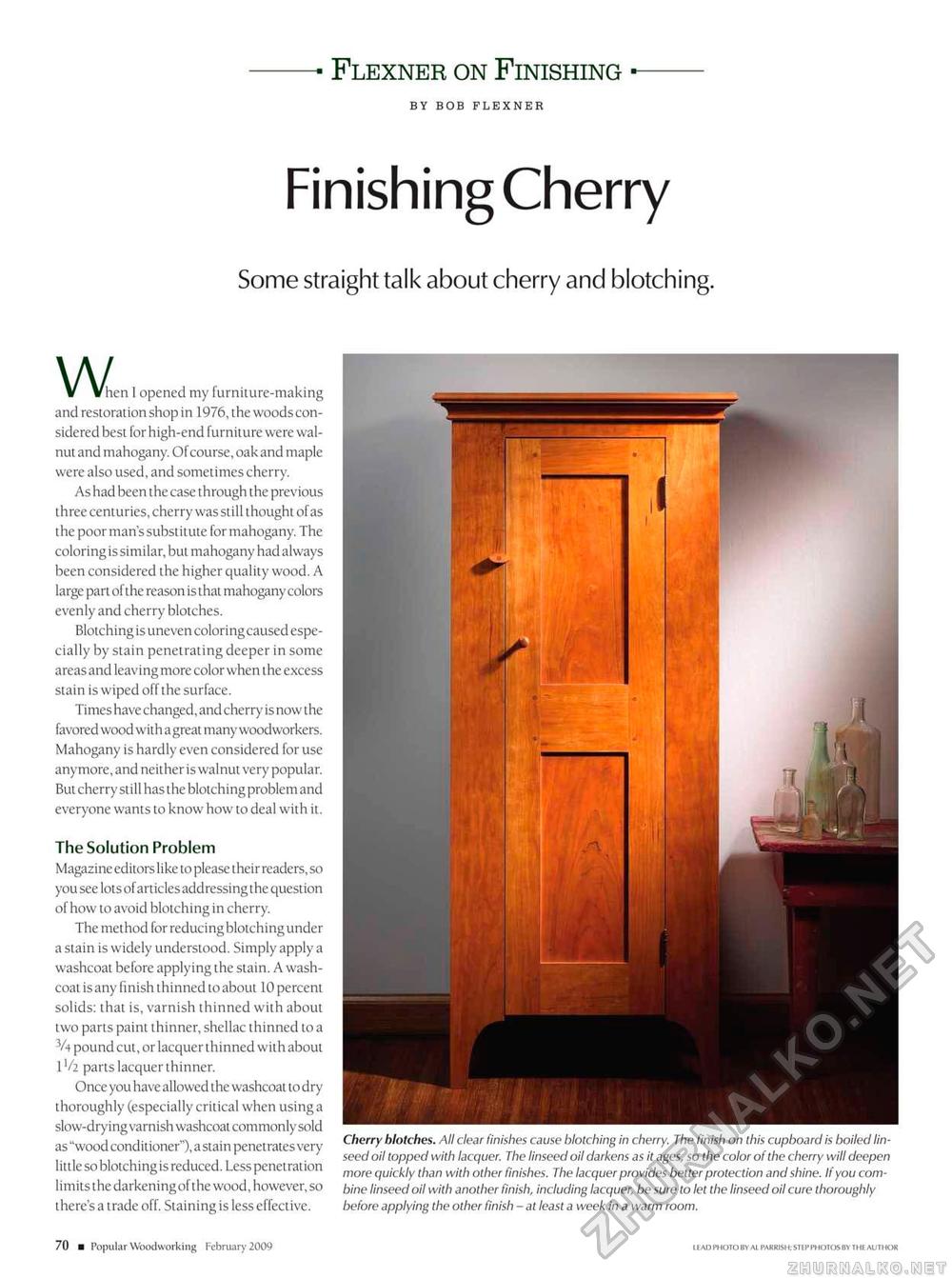

■ Flexner on Finishing ■ BY BOB FLEXNER Finishing Cherry Some straight talk about cherry and blotching. w If hen I opened my furniture-making and restoration shop in 1976, the woods considered best for high-end furniture were walnut and mahogany. Of course, oak and maple were also used, and sometimes cherry. As had been the case through the previous three centuries, cherry was still thought of as the poor man's substitute for mahogany. The coloring is similar, but mahogany had always been considered the higher quality wood. A large part of the reason is that mahogany colors evenly and cherry blotches. Blotching is uneven coloring caused especially by stain penetrating deeper in some areas and leaving more color when the excess stain is wiped off the surface. Times have changed, and cherry is now the favored wood with a great many woodworkers. Mahogany is hardly even considered for use anymore, and neither is walnut very popular. But cherry still has the blotching problem and everyone wants to know how to deal with it. The Solution Problem Magazine editors like to please their readers, so you see lots of articles addressing the question of how to avoid blotching in cherry. The method for reducing blotching under a stain is widely understood. Simply apply a washcoat before applying the stain. A wash-coat is any finish thinned to about 10 percent solids: that is, varnish thinned with about two parts paint thinner, shellac thinned to a 3A pound cut, or lacquer thinned with about l'/2 parts lacquer thinner. Once you have allowed the washcoat to dry thoroughly (especially critical when using a slow-drying varnish washcoat commonly sold as "wood conditioner"), a stain penetrates very little soblotchingis reduced. Less penetration limits the darkening of the wood, however, so there's a trade off. Staining is less effective. Cherry blotches. All clear finishes cause blotching in cherry. The finish on this cupboard is boiled linseed oil topped with lacquer. The linseed oil darkens as it ages, so the color of the cherry will deepen more quickly than with other finishes. The lacquer provides better protection and shine. If you combine linseed oil with another finish, including lacquer, be sure to let the linseed oil cure thoroughly before applying the other finish - at least a week in a warm room. 70 ■ Popular Woodworking February 2009 |