92, страница 45

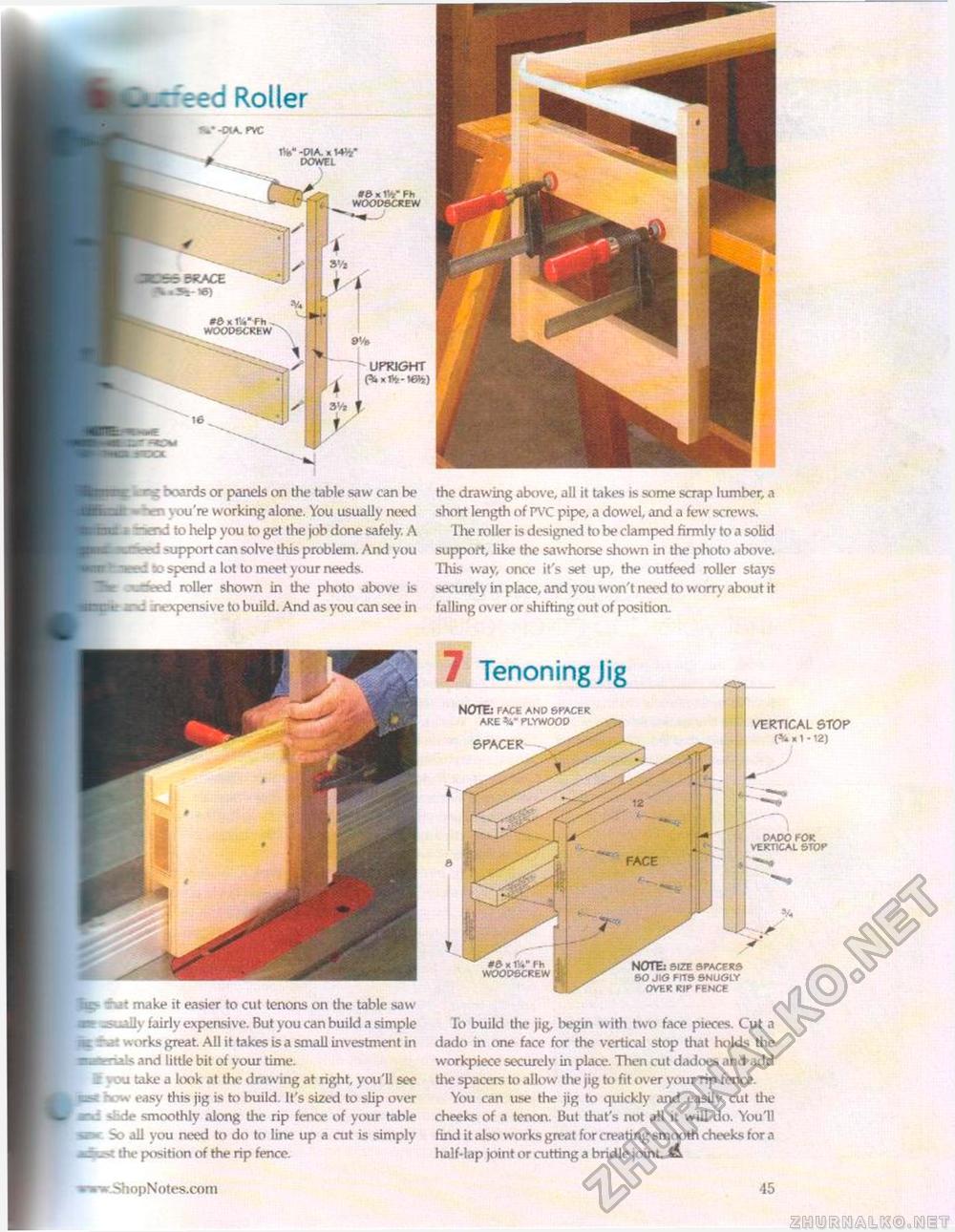

eed Roller or panels on the table saw can be you're working alone. Vou usually need to help you to get the job done safely. A support can solve this problem. And you to spend a lot to meet your needs. roller shown in the photo above is to build. And as you can see in the drawing above, all it takes is some scrap lumber, a short length of PVC pipe, a dowel, and a few screws. The roller is designed to be clamped firmly to a solid support, like the sawhorse shown in the photo above. This way, once it's set up, the outfeed roller stays securely in place, and you won't need to worry about it tailing over or shifting out of position. ■j Wt J UPKJGHT K-ShopNotes.com make it easier to cut tenons on the table saw fairly expensive. But you can build a simple •vorks great. All it takes is a small investment in bit of your time. It v chi take a look at the drawing at right, you'll see easy this jig is to build It's sized to slip over smoothly along the rip fence of your table fo all you need to do to line up a cut is simply the position of the rip fence. 7 Tenoning Jig NOTE: SIZE SPACERS 60 JIG FITS SNUGLY OVER RIP FENCE VERTICAL stop piKl- 12) DADO FOR VERTICAL STOP NOTE: PACE AND SPACER ARE PLYWOOD To build the jig, begin with two face pieces. Cut a dado in one face for the vertical stop that holds the workpiece securely in place. Then cut dadoes and add the spacers to allow the jig to fit over your rip fence. You can use the jig to quickly and easily cut the cheeks of a tenon. But that's not all it will do. You'll find it aLso works great for creating smcx>th cheeks for a half-lap joint or cutting a bridle joint. fL 45 |