92, страница 50

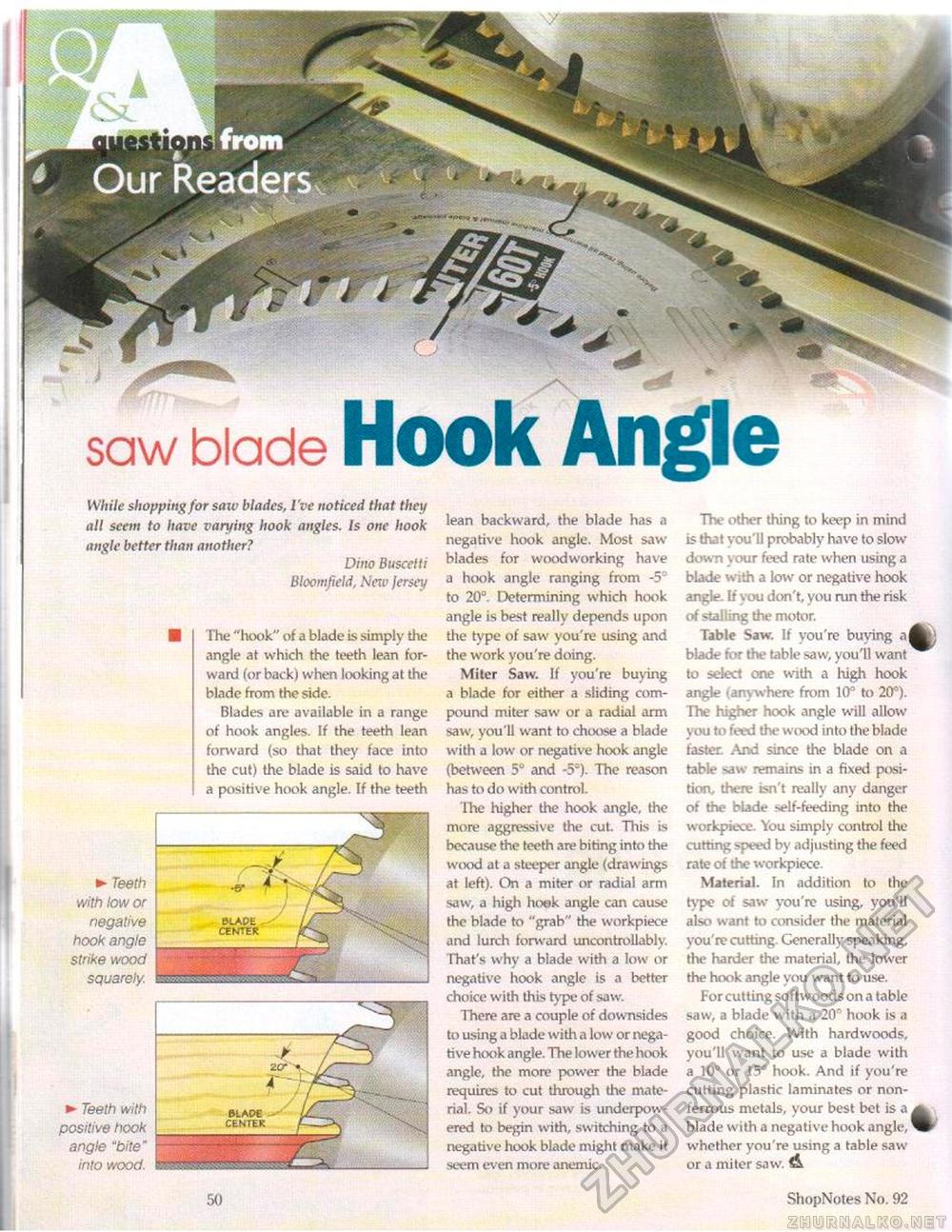

saw blade Hook AngleWhile shopping for saw blades, I've noticed that they all seem to have varying hook angles. Is one hook angle better than another? Ditto Buscetti Bloomfield, Neiv jersey ► Teeth with low or negative hook angle strike wood squarely. The "hcx)k" of a blade is simply the angle at which the teeth lean forward (or back) when looking at the blade from the side. Blades are available in a range of hook angles. If the teeth lean forward (so that they face into the cut) the blade is said to have a positive hook angle. If the teeth ► Teeth with positive hook angle "bite" into wood. lean backward, the blade has a negative hook angle. Most saw blades for woodworking have a hook angle ranging from -5° to 20°. Determining which hook angle is best really depends upon the type of saw you're using and the work you're doing. Miter Saw. If you're buying a blade for either a sliding compound miter saw or a radial arm saw, you'll want to choose a blade with a low or negative hook angle (between 5° and -5°). The reason has to do with control. Ihe higher the hook angle, the more aggressive the cut. This is because the teeth are biting into the wood at a steeper angle (drawings at left). On a miter or radial arm saw, a high hook angle can cause the blade to "grab" the workpiece and lurch forward uncontrollably. That's why a blade with a low or negative hook angle is a better choice with this type of saw. There are a couple of downsides to using a blade with a low or negative hook angle. The lower the hook angle, the more power the blade requires to cut through the material. So if your saw is underpowered to begin with, switching to a negative hook blade might make it seem even more anemic. The other thing to keep in mind is that you'll probably have to slowdown your feed rate when using a blade with a low or negative hook angle. If you don't, you run the risk of stalling the motor. Table Saw. If you're buying blade for the table saw, you'll want to select one with a high hook angle (anywhere from 10° to 20°). The higher hook angle will allow you to feed the wood into the blade faster And since the blade on a table >av\ remains in a fixed ptwi-tion, there isn't really any danger of the blade self-feeding into the workpiece You simply control the cutting speed by adjusting the feed rate of the workpiece. Material. In addition to the type erf saw you're using, you'll also want to consider the material you're cutting Generally speaking, the harder the material, the lower the hook angle you want to use. For cutting softwoods on a table saw, a blade with a 20° hook is a good choice. With hardwoods, you'll want to use a blade with a 10° or 15° hook. And if you're cutting plastic laminates or non-ferrous metals, your best bet is a ^ blade with a negative hook angle, ^P* whether you're using a table saw or a miter saw. A 50 ShopNotes No. 1)2 |