Woodworker's Journal 1981-5-6, страница 11

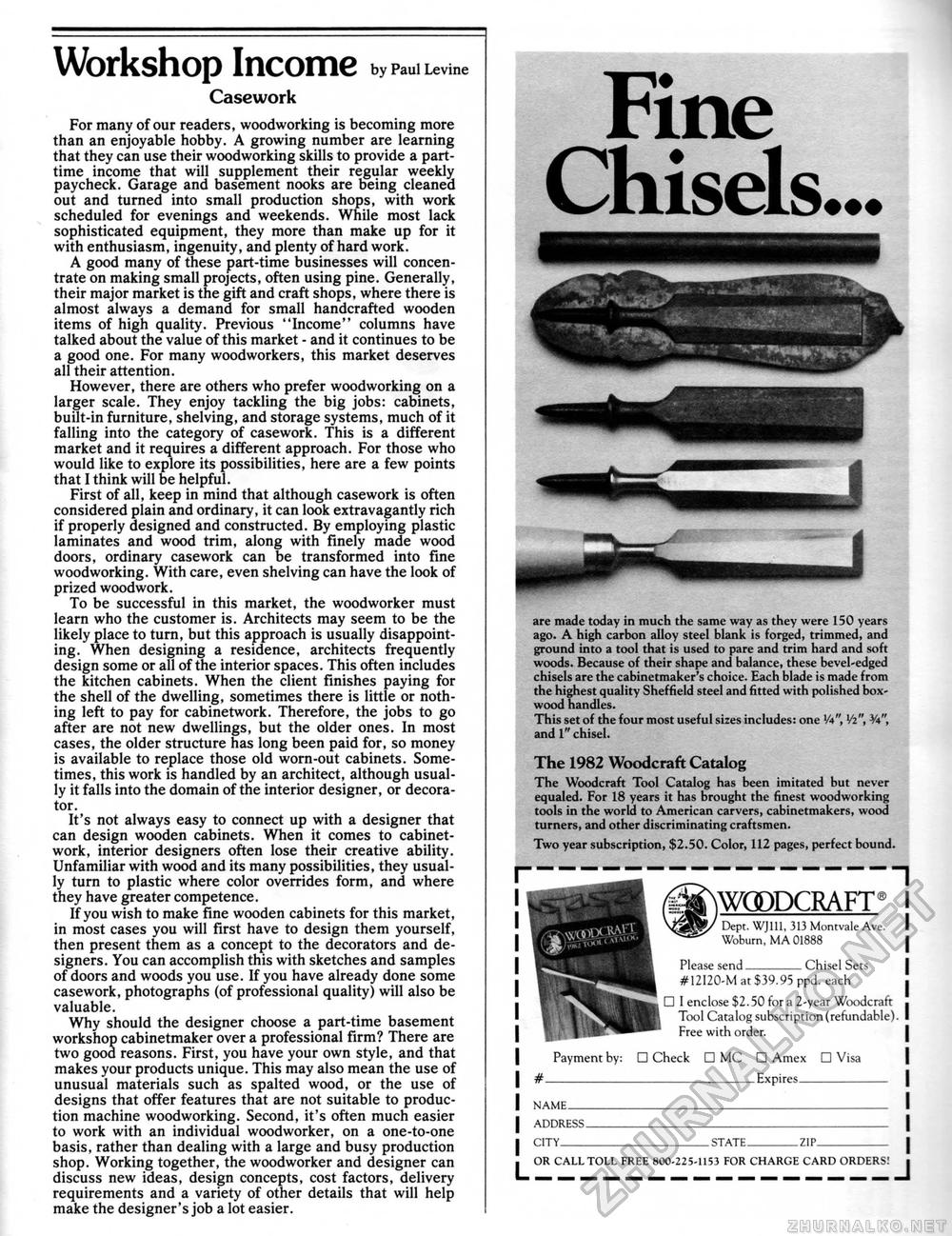

Workshop Income by Paul Levine Casework For many of our readers, woodworking is becoming more than an enjoyable hobby. A growing number are learning that they can use their woodworking skills to provide a part-time income that will supplement their regular weekly paycheck. Garage and basement nooks are being cleaned out and turned into small production shops, with work scheduled for evenings and weekends. While most lack sophisticated equipment, they more than make up for it with enthusiasm, ingenuity, and plenty of hard work. A good many of these part-time businesses will concentrate on making small projects, often using pine. Generally, their major market is the gift and craft shops, where there is almost always a demand for small handcrafted wooden items of high quality. Previous "Income" columns have talked about the value of this market - and it continues to be a good one. For many woodworkers, this market deserves all their attention. However, there are others who prefer woodworking on a larger scale. They enjoy tackling the big jobs: cabinets, built-in furniture, shelving, and storage systems, much of it falling into the category of casework. This is a different market and it requires a different approach. For those who would like to explore its possibilities, here are a few points that I think will be helpful. First of all, keep in mind that although casework is often considered plain and ordinary, it can look extravagantly rich if properly designed and constructed. By employing plastic laminates and wood trim, along with finely made wood doors, ordinary casework can be transformed into fine woodworking. With care, even shelving can have the look of prized woodwork. To be successful in this market, the woodworker must learn who the customer is. Architects may seem to be the likely place to turn, but this approach is usually disappointing. When designing a residence, architects frequently design some or all of the interior spaces. This often includes the kitchen cabinets. When the client finishes paying for the shell of the dwelling, sometimes there is little or nothing left to pay for cabinetwork. Therefore, the jobs to go after are not new dwellings, but the older ones. In most cases, the older structure has long been paid for, so money is available to replace those old worn-out cabinets. Sometimes, this work is handled by an architect, although usually it falls into the domain of the interior designer, or decorator. It's not always easy to connect up with a designer that can design wooden cabinets. When it comes to cabinetwork, interior designers often lose their creative ability. Unfamiliar with wood and its many possibilities, they usually turn to plastic where color overrides form, and where they have greater competence. If you wish to make fine wooden cabinets for this market, in most cases you will first have to design them yourself, then present them as a concept to the decorators and designers. You can accomplish this with sketches and samples of doors and woods you use. If you have already done some casework, photographs (of professional quality) will also be valuable. Why should the designer choose a part-time basement workshop cabinetmaker over a professional firm? There are two good reasons. First, you have your own style, and that makes your products unique. This may also mean the use of unusual materials such as spalted wood, or the use of designs that offer features that are not suitable to production machine woodworking. Second, it's often much easier to work with an individual woodworker, on a one-to-one basis, rather than dealing with a large and busy production shop. Working together, the woodworker and designer can discuss new ideas, design concepts, cost factors, delivery requirements and a variety of other details that will help make the designer's job a lot easier. are made today in much the same way as they were 150 years ago. A high carbon alloy steel blank is forged, trimmed, and ground into a tool that is used to pare and trim hard and soft woods. Because of their shape and balance, these bevel'edged chisels are the cabinetmaker's choice. Each blade is made from the highest quality Sheffield steel and fitted with polished boxwood handles. This set of the four most useful sizes includes: one 'A", Vi", W, and 1" chisel. The 1982 Woodcraft Catalog The Woodcraft Tool Catalog has been imitated but never equaled. For 18 years it has brought the finest woodworking tools in the world to American carvers, cabinetmakers, wood turners, and other discriminating craftsmen. Two year subscription, $2.50. Color, 112 pages, perfect bound. Please send _ iWGDDCRAFT Dept. WJ1U, 313 Montvale Ave. Woburn, MA 01888 . Chisel Sets #12I20-M at $39.95 ppd. each □ I enclose $2.50 for a 2-year Woodcraft Tool Catalog subscription(refundable). Free with order. ADDRESS CITY □ Check □ MC STATE- □ Amex Expires_ □ Visa _Z1P_ ^ OR CALL TOLL FREE 800-225-1153 FOR CHARGE CARD ORDERS! |