Woodworker's Journal 1981-5-6, страница 24

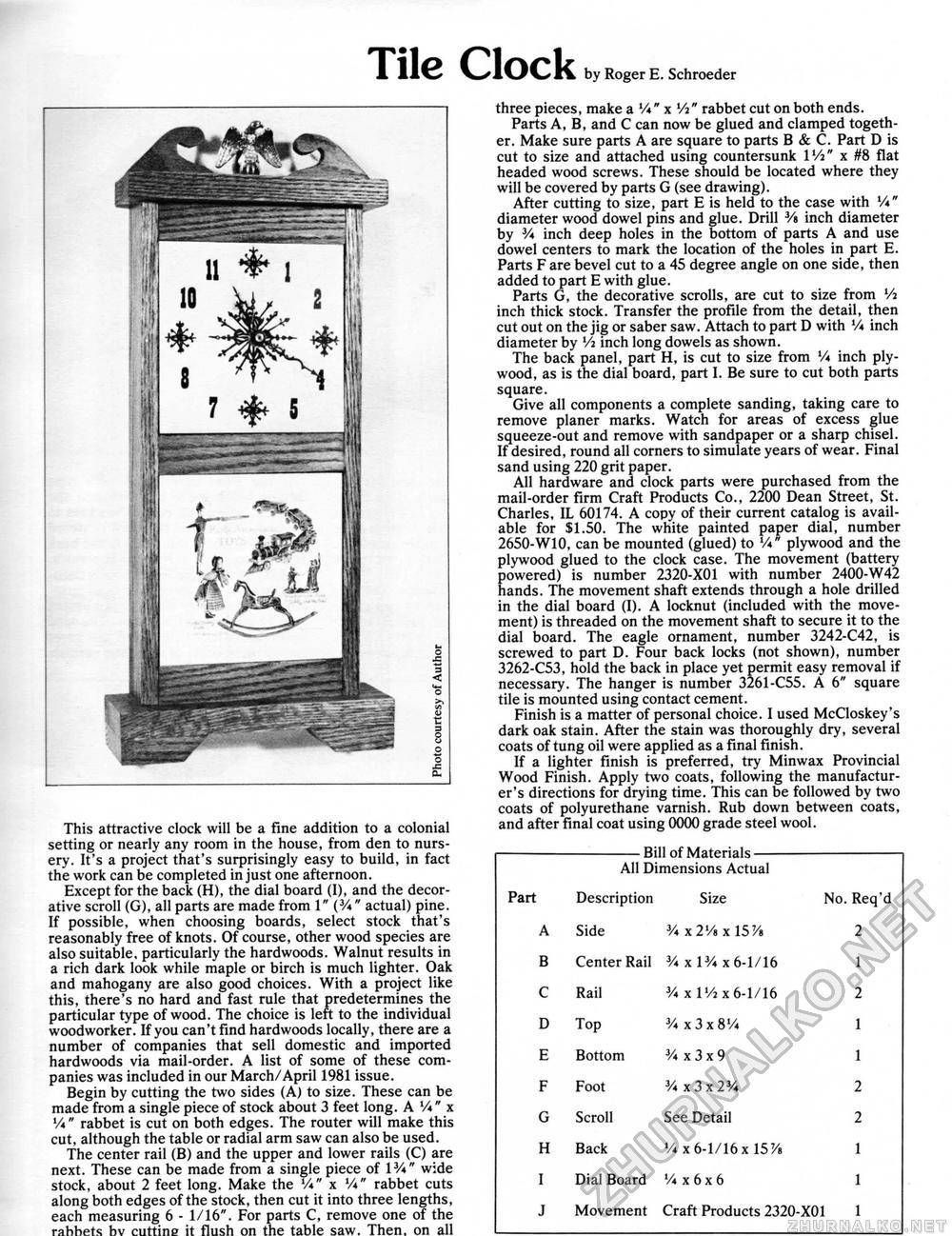

Tile Clock by Roger E. Schroeder This attractive clock will be a fine addition to a colonial setting or nearly any room in the house, from den to nursery. It's a project that's surprisingly easy to build, in fact the work can be completed in just one afternoon. Except for the back (H), the dial board (I), and the decorative scroll (G), all parts are made from 1" (V* " actual) pine. If possible, when choosing boards, select stock that's reasonably free of knots. Of course, other wood species are also suitable, particularly the hardwoods. Walnut results in a rich dark look while maple or birch is much lighter. Oak and mahogany are also good choices. With a project like this, there's no hard and fast rule that predetermines the particular type of wood. The choice is left to the individual woodworker. If you can't find hardwoods locally, there are a number of companies that sell domestic and imported hardwoods via mail-order. A list of some of these companies was included in our March/April 1981 issue. Begin by cutting the two sides (A) to size. These can be made from a single piece of stock about 3 feet long. A Vi" x Vi" rabbet is cut on both edges. The router will make this cut, although the table or radial arm saw can also be used. The center rail (B) and the upper and lower rails (C) are next. These can be made from a single piece of 13A" wide stock, about 2 feet long. Make the Vi" x Vi" rabbet cuts along both edges of the stock, then cut it into three lengths, each measuring 6 - 1/16". For parts C, remove one of the rabbets bv cutting it flush on the table saw. Then, on all three pieces, make a Vi" x Vi" rabbet cut on both ends. Parts A, B, and C can now be glued and clamped together. Make sure parts A are square to parts B & C. Part D is cut to size and attached using countersunk IVi" x #8 flat headed wood screws. These should be located where they will be covered by parts G (see drawing). After cutting to size, part E is held to the case with Vi" diameter wood dowel pins and glue. Drill V» inch diameter by Vi inch deep holes in the bottom of parts A and use dowel centers to mark the location of the holes in part E. Parts F are bevel cut to a 45 degree angle on one side, then added to part E with glue. Parts G, the decorative scrolls, are cut to size from Vi inch thick stock. Transfer the profile from the detail, then cut out on the jig or saber saw. Attach to part D with Vi inch diameter by Vi inch long dowels as shown. The back panel, part H, is cut to size from Vi inch plywood, as is the dial board, part I. Be sure to cut both parts square. Give all components a complete sanding, taking care to remove planer marks. Watch for areas of excess glue squeeze-out and remove with sandpaper or a sharp chisel. If desired, round all corners to simulate years of wear. Final sand using 220 grit paper. All hardware and clock parts were purchased from the mail-order firm Craft Products Co., 2200 Dean Street, St. Charles, IL 60174. A copy of their current catalog is available for $1.50. The white painted paper dial, number 2650-W10, can be mounted (glued) to Vi" plywood and the plywood glued to the clock case. The movement (battery powered) is number 2320-X01 with number 2400-W42 hands. The movement shaft extends through a hole drilled in the dial board (I). A locknut (included with the movement) is threaded on the movement shaft to secure it to the dial board. The eagle ornament, number 3242-C42, is screwed to part D. Four back locks (not shown), number 3262-C53, hold the back in place yet permit easy removal if necessary. The hanger is number 3261-C55. A 6" square tile is mounted using contact cement. Finish is a matter of personal choice. I used McCloskey's dark oak stain. After the stain was thoroughly dry, several coats of tung oil were applied as a final finish. If a lighter finish is preferred, try Minwax Provincial Wood Finish. Apply two coats, following the manufacturer's directions for drying time. This can be followed by two coats of polyurethane varnish. Rub down between coats, and after final coat using 0000 grade steel wool. -Bill of Materials- All Dimensions Actual All Dimensions Actual

|

||||||||||||||||||||||||||||||||||||||||||||