Woodworker's Journal 1983-7-2, страница 14

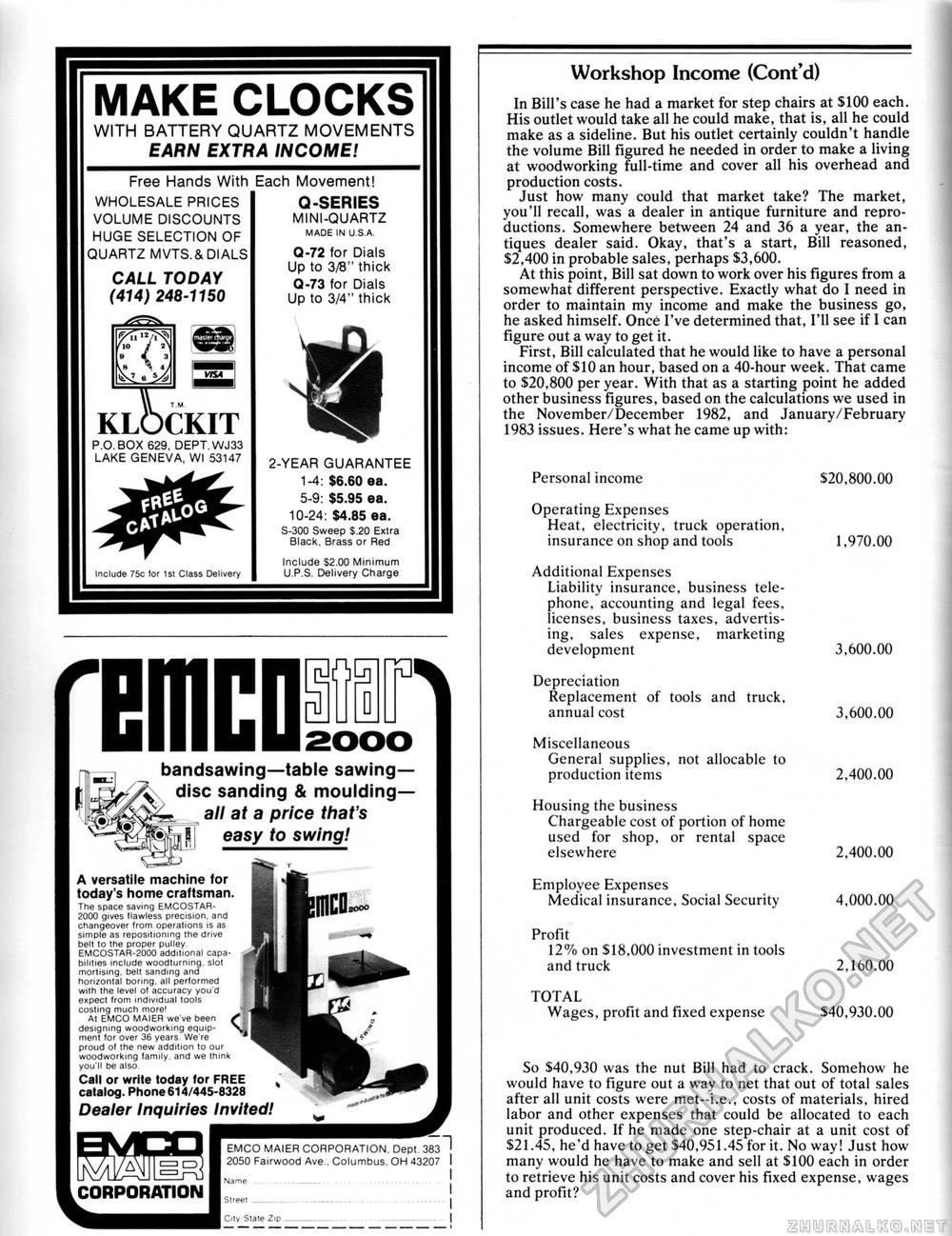

MAKE CLOCKS WITH BATTERY QUARTZ MOVEMENTS EARN EXTRA INCOME! Free Hands With WHOLESALE PRICES VOLUME DISCOUNTS HUGE SELECTION OF QUARTZ MVTS.& DIALS CALL TODAY (414) 248-1150 KLOCKIT P.O.BOX 629, DEPT.WJ33 LAKE GENEVA, Wl 53147 Include 75c for 1st Class Delivery Each Movement! Q-SERIES MINI-QUARTZ MADE IN U.S.A. Q-72 for Dials Up to 3/8" thick Q-73 for Dials Up to 3/4" thick 2-YEAR GUARANTEE 1-4: $6.60 ea. 5-9: $5.95 ea. 10-24: $4.85 ea. S-300 Sweep $.20 Extra Black. Brass or Red Include $2.00 Minimum U.P.S. Delivery Charge bandsawing—table sawing-disc sanding & moulding-all at a price that's easy to swing! A versatile machine for today's home craftsman. The space saving EMCOSTAR-2000 gives flawless precision, and changeover from operations is as simple as repositioning the drive belt to the proper pulley EMCOSTAR-2000 additional capabilities include woodturning. slot mortising, bell sanding and horizontal boring, all performed with the level of accuracy you'd expect from individual tools costing much more1 At EMCO MAIER we've been designing woodworking equipment for over 36 years We're proud of the new addition to our woodworking family, and we think you'll be also Call or write today for FREE catalog. Phone 614/445-8328 Dealer Inquiries Invited! .CORPORATION EMCO MAIER CORPORATION. Dept. 383 2050 Fairwood Ave , Columbus. OH 43207 I Name I Street -------- I City State Zip 1 Workshop Income (Cont'd) In Bill's case he had a market for step chairs at $100 each. His outlet would take all he could make, that is, all he could make as a sideline. But his outlet certainly couldn't handle the volume Bill figured he needed in order to make a living at woodworking full-time and cover all his overhead and production costs. Just how many could that market take? The market, you'll recall, was a dealer in antique furniture and reproductions. Somewhere between 24 and 36 a year, the antiques dealer said. Okay, that's a start, Bill reasoned, $2,400 in probable sales, perhaps $3,600. At this point, Bill sat down to work over his figures from a somewhat different perspective. Exactly what do I need in order to maintain my income and make the business go, he asked himself. Once I've determined that, I'll see if I can figure out a way to get it. First, Bill calculated that he would like to have a personal income of $10 an hour, based on a 40-hour week. That came to $20,800 per year. With that as a starting point he added other business figures, based on the calculations we used in the November/December 1982, and January/February 1983 issues. Here's what he came up with: Personal income $20,800.00 Operating Expenses Heat, electricity, truck operation, insurance on shop and tools 1,970.00 Additional Expenses Liability insurance, business telephone, accounting and legal fees, licenses, business taxes, advertising, sales expense, marketing development 3,600.00 Depreciation Replacement of tools and truck, annual cost 3,600.00 Miscellaneous General supplies, not allocable to production items 2,400.00 Housing the business Chargeable cost of portion of home used for shop, or rental space elsewhere 2,400.00 Employee Expenses Medical insurance. Social Security 4.000.00 Profit 12% on $18,000 investment in tools and truck 2,160.00 TOTAL Wages, profit and fixed expense $40,930.00 So $40,930 was the nut Bill had to crack. Somehow he would have to figure out a way to net that out of total sales after all unit costs were met-i.e., costs of materials, hired labor and other expenses that could be allocated to each unit produced. If he made one step-chair at a unit cost of $21.45, he'd have to get $40,951.45 for it. No way! Just how many would he have to make and sell at $100 each in order to retrieve his unit costs and cover his fixed expense, wages and profit? |