Woodworker's Journal 1983-7-4, страница 49

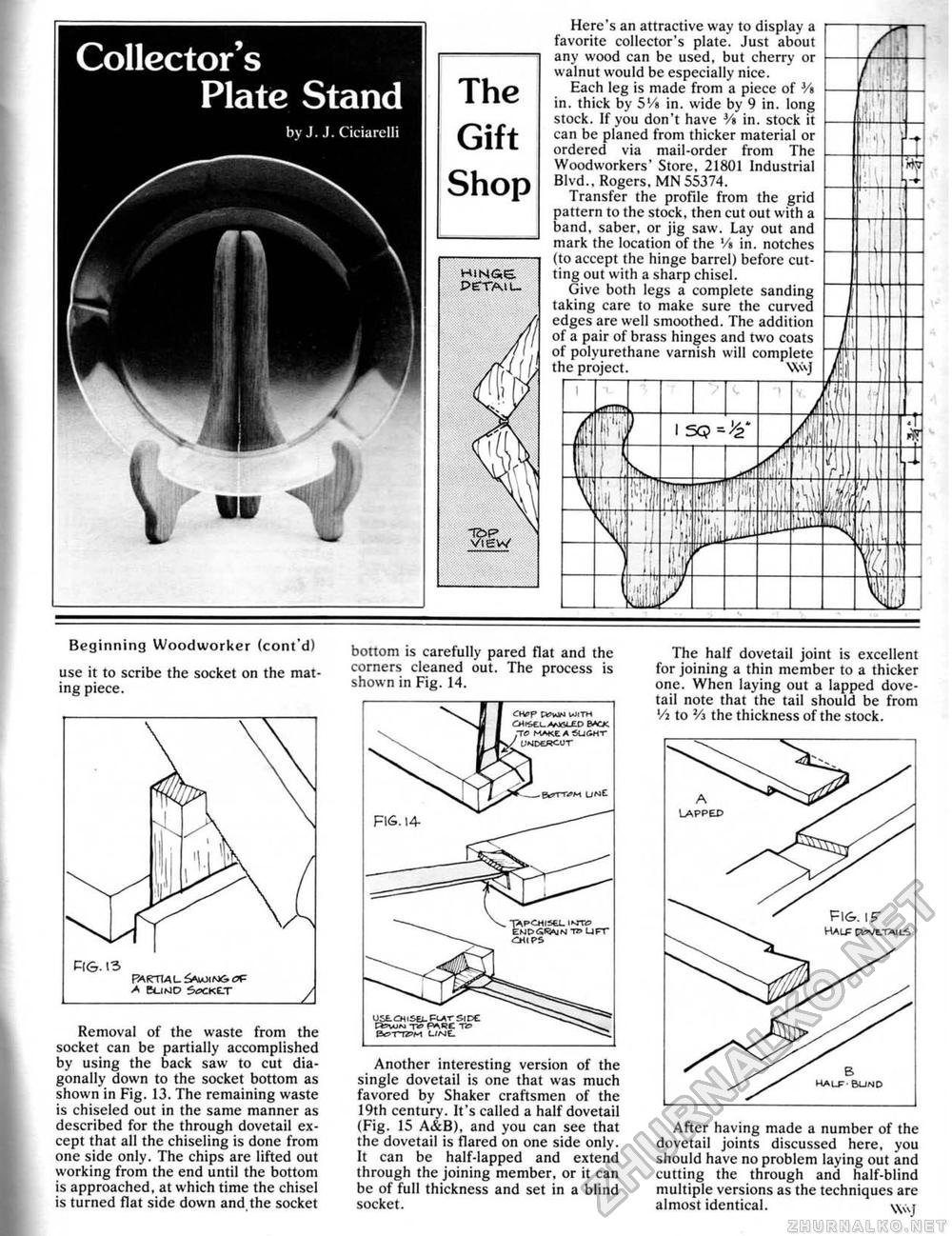

The Gift ShopBeginning Woodworker (cont'd) use it to scribe the socket on the mat ing piece. bottom is carefully pared flat and the corners cleaned out. The process is shown in Fig. 14, The half dovetail joint is excellent for joining a thin member to a thicker one. When laying out a lapped dovetail note that 'the tail should be from Vi to % the thickness of the stock. half rsme.toius ENDSSJMW TP LIFT .CHIPS Removal of the waste from the socket can be partially accomplished by using the back saw to cut diagonally down to the socket bottom as shown in Fig. 13. The remaining waste is chiseled out in the same manner as described for the through dovetail except that all the chiseling is done from one side only. The chips are lifted out working from the end until the bottom is approached, at which time the chisel is turned flat side down and the socket Another interesting version of the single dovetail is one that was much favored by Shaker craftsmen of the 19th century. It's called a half dovetail (Fig. 15 A&B), and you can see that the dovetail is flared on one side only. It can be half-lapped and extend through the joining member, or it can be of full thickness and set in a blind socket. half1' Bund After having made a number of the dovetail joints discussed here, you should have no problem laying out and cutting the through and half-blind multiple versions as the techniques are almost identical. km PETAlU Here's an attractive way to display a favorite collector's plate". Just about any wood can be used, but cherry or walnut would be especially nice, Each leg is made from a piece of Vt in. thick by 5Vt in. wide by 9 in. long stock. If you don't have Vt in. stock it can be planed from thicker material or ordered via mail-order from The Woodworkers' Store, 21801 Industrial Blvd., Rogers. MN 55374. Transfer the profile from the grid pattern to the stock, then cut out with a band, saber, or jig saw. Lay out and mark the location of the Vt in, notches (to accept the hinge barrel) before cutting out with a sharp chisel. Give both legs a complete sanding taking care to make sure the curved edges are well smoothed. The addition of a pair of brass hinges and two coats of polyurethane varnish will complete the project. |