Woodworker's Journal 1983-7-5, страница 33

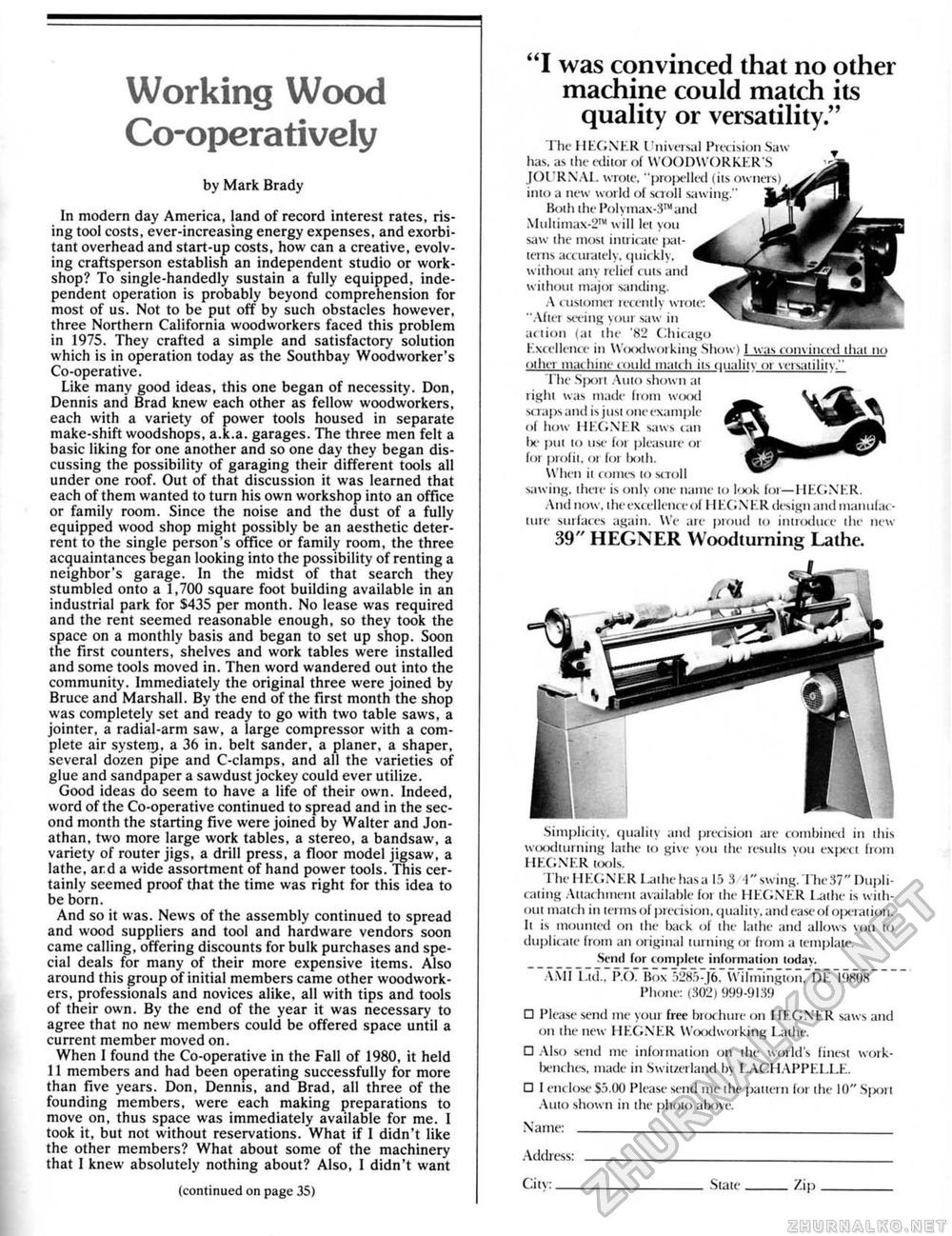

Working Wood Co-operatively by Mark Brady in modern day America, land of record interest rates, rising tool costs, ever-increasing energy expenses, and exorbitant overhead and start-up costs, how can a creative, evolving craftsperson establish an independent studio or workshop? To single-handedly sustain a fully equipped, independent operation is probably beyond comprehension for most of us. Not to be put off by such obstacles however, three Northern California woodworkers faced this problem in 1975. They crafted a simple and satisfactory solution which is in operation today as the Southbay Woodworker's Co-operative. Like many good ideas, this one began of necessity. Don, Dennis and Brad knew each other as fellow woodworkers, each with a variety of power tools housed in separate make-shift woodshops. a.k.a. garages. The three men felt a basic liking for one another and so one day they began discussing the possibility of garaging their different tools all under one roof. Out of that discussion it was learned that each of them wanted to turn his own workshop into an office or family room. Since the noise and the dust of a fully equipped wood shop might possibly be an aesthetic deterrent to the single person's office or family room, the three acquaintances began looking into the possibility of renting a neighbor's garage. In the midst of that search they stumbled onto a 1,700 square foot building available in an industrial park for S435 per month. No lease was required and the rent seemed reasonable enough, so they took the space on a monthly basis and began to set up shop. Soon the first counters, shelves and work tables were installed and some tools moved in. Then word wandered out into the community. Immediately the original three were joined by Bruce and Marshall. By the end of the first month the shop was completely set and ready to go with two table saws, a jointer, a radial-arm saw, a large compressor with a complete air systeip, a 36 in. belt sander, a planer, a shaper, several do/.en pipe and C-clamps. and all the varieties of glue and sandpaper a sawdust jockey could ever utilize. Good ideas do seem to have a life of their own. Indeed, word of the Co-operative continued to spread and in the second month the starting five were joined by Walter and Jonathan, two more large work tables, a stereo, a bandsaw, a variety of router jigs, a drill press, a floor model jigsaw, a lathe, ar.d a wide assortment of hand power tools. This certainly seemed proof that the time was right for this idea to be born. And so it was. News of the assembly continued to spread and wood suppliers and tool and hardware vendors soon came calling, offering discounts for bulk purchases and special deals for many of their more expensive items. Also around this group of initial members came other woodworkers, professionals and novices alike, all with tips and tools of their own. By the end of the year it was necessary to agree that no new members could be offered space until a current member moved on. When I found the Co-operative in the Fall of 1980, it held 11 members and had been operating successfully for more than five years, Don, Dennis, and Brad, all three of the founding members, were each making preparations to move on, thus space was immediately available for me. I took it, but not without reservations. What if 1 didn't like the other members? What about some of the machinery that I knew absolutely nothing about? Also, I didn't want (continued on page 35) "I was convinced that no other machine could match its quality or versatility." Simplicity, quality and precision are combined in this woodturning lathe to give you the results you exjx'c i from HEGNER tools. The HEGNER Lathe has a 15 3 •Tswing.The37"Dupli* eating Attachment available for the HEGNER Lathe ts within it match in terms of precision, quality, and ease ol opera don. Ii is mounted on the back of the lathe and allows you to duplicate from an original turning dr from a template. Send tor complete information today. " "AMI Lid.rP.oT Box Mftfr-jV"WiImington,~DE WdtT" Phone: (302)999-9139 P Please send me your free brochure on HEGNER saws and on the new* HEGNER Woodworking Lathe. □ Also send me information on the world's finest workbenches, made in Switzerland by LACHAPPELLE. □ I enclose $5.00 Please send me the pattern (or the 10" S|x h t Auto shown in the photo above. Name: _ Address: City:_ State. Zip . The HEGNER Universal Precision Saw has, as the editor of WOODWORKER'S JOURNAL wrote, "propelled (its owners) into a new world of scroll sawing." B< »th the Polymax-3™ and Muhimax-2™ will let you saw the most intricate pat-term accurately, quickly, without am relief cuts and without majot sanding. A customer recently wrote: "Aftet seeing your saw in action (at the Chicago Excellence in Woodworking Show) 1 was comincetl that no ul lie; mac linn-11 mid iti.ili I) iis c | u.ilm or vcisatilit \ The S|xiri Auto shown at l ight was made from wood straps and is just one example oj how HEGNER saws can lie pin to use fur pleasure ot lot profit, ot for Ixith. When ii comes to scroll sawing, there is only mic name to l< x>k foi — 11EGNER. And now, the excellence of HEGNER design and manufacture surfaces again. We are proud to introduce the new 39" HEGNER Woodturning Lathe. |